Fibre Rigging - Custom Build Instructions

Jimmy Green Advisory - Loop splices are pulled out straight and together for measurement purposes.

The Jimmy Green Rigging Sales Team are happy to advise you on any aspect of the custom build process for ordering your fibre rigging

There is a toggle to switch from Custom Build to a simple Cut Length where applicable.

CUT LENGTH ROPE MEASUREMENT ADVISORY

Follow the Jimmy Green Custom Build Process to get an instant quote and complete the order yourself

- Step 1 - Splicing, optional - Choose your finish for one end - not making a selection will result in a basic knife/scissors cut through wrapped tape

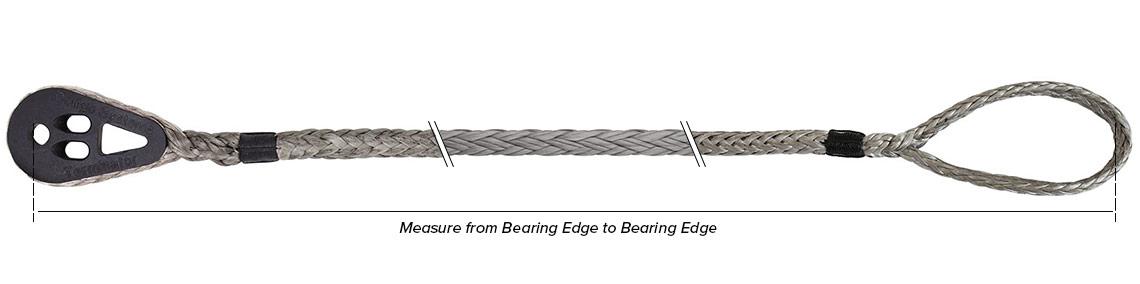

- Step 2 - Rope, required - Select the rope and enter your finished length - this will be the length from bearing edge to bearing edge

- Step 3 - Splicing, optional - Choose your finish for the other end - not making a selection will result in a basic knife/scissors cut through wrapped tape

- Step 4 - Add a Custom Product Name, optional - add any notes for yourself or the Rigging Team as necessary

N.B. It is not possible to make a neat heat sealing in 100% Dyneema or Vectran.

Once you have made your selection in all the drop-down boxes, our website will generate:

- a picture version of what you have chosen

- an overall length

- a price including VAT, or excluding VAT if you are signed in with an export delivery address

Jimmy Green Custom Build Fibre Rigging Advisory

The website will accept a length to 3 decimal points. However, this is not usually practicable.

For short finished lengths of 12 strand Dyneema with a critical high load, super low stretch, control line application, the Jimmy Green Rigging Team aim for a bearing edge to bearing edge measurement which is accurate to within + or - the diameter of the rope.

However, Jimmy Green Marine will only accept responsibility for bearing edge-to-bearing edge measurements to within 2 x + or - the diameter of the line.

For a longer sheet, halyard, or simple control line, the Jimmy Green Rigging Team will aim for a generous finished length, but for the price of a metre or two, it is advisable to round up your estimate of the length required to avoid an inconvenient result.

Jimmy Green Rigging Team Whipping Advisory

If you don't need a splice, a whipping is advisable to prevent the end from unraveling and to maintain the integrity of the rope construction.

This not only prevents the end from fraying but also keeps the two parts of the line in synchronised tension.

If the core and cover can move independently, the line integrity of the line will be compromised.

We offer a heat sealing option which melts and moulds the end of the rope, and the additional option of a heat shrink band to keep the end of the line bound together.

However, these are only temporary solutions, and a proper whipping is always recommended to guarantee the integrity of the line.

Of course, we understand that you may wish to apply the finishing touch yourself, and we sell all the FIDS, TOOLS AND WHIPPING TWINES to add to your onboard service kit.

The Next Steps:

- Check the item is designed as you wish. You can alter any of the boxes and the website will update the picture and the price.

- Check the quantity that you want to purchase and click the orange Add to Basket button to put it in your shopping basket

- Select Continue Shopping or Proceed to Checkout

- To view the items you have selected, go to your basket or direct to checkout

Additional Notes for your Custom Build

You can add a note for your own benefit or advise the Rigging Team of a specific requirement.

This note will appear in the product description in your basket

Common examples:

- Add a name for identifying your selection

- Splice on a fitting that is not in the custom build drop-down menu

- Request a different loop size

Jimmy Green Additional Fitting Advisory

When a fitting is requested from outside the custom build process, it will be assumed that the finished length is measured to the bearing edge of the additional fitting(s)

In other words, the finished length will include any shackles, hooks or fittings.

The same principle applies to special requests for different lengths of loops.

The Jimmy Green Rigging Team Finished Length Process for Fibre Rigging Lines with a splice at both ends

- Splice one end

- Secure the spliced end to the bearing edge pin on the splicing bench

- Lay the rope out straight against the fixed tape measure

- Calculate and mark the turning point for the splice at the other end of the rope

- Estimate the extra length required to complete the splice and cut accordingly

- Complete the second splice

- Check the finished length against your order

Quality Control

The Jimmy Green Rigging Team undertake to check your rope meticulously during the production process to ensure that it is 100% First Quality.

The Jimmy Green Despatch Team make a second thorough quality inspection of each item, including a careful check that it matches your order, before packing it into your parcel.

Additional Information

The finished length is measured from the bearing edge to the bearing edge = the inside face of a loop/thimble where a shackle pin would take the load and therefore NOT the overall outside length.

The splicing price includes the extra rope required to make the splice and meet the overall finished length

Please take extra care when ordering because once a bespoke item has been started (cut) it can neither be cancelled nor returned for a refund.