How to Choose between Plain, Roller and Ball Bearing Blocks

Blocks, also known as pulleys, are available with plain, roller or ball bearings.

Select the bearing type according to the use that the block will serve onboard.

Plain Bearing Blocks

The plain bearing block, mainstay of the running rigging on a cruising yacht, is developed from the traditional dead eye, which has no moving parts and originated as a piece of hardwood, e.g. lignum vitae, with carefully grooved holes through it. Things have gone full circle with the advent of the modern low-friction ring equivalent.

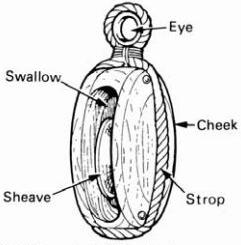

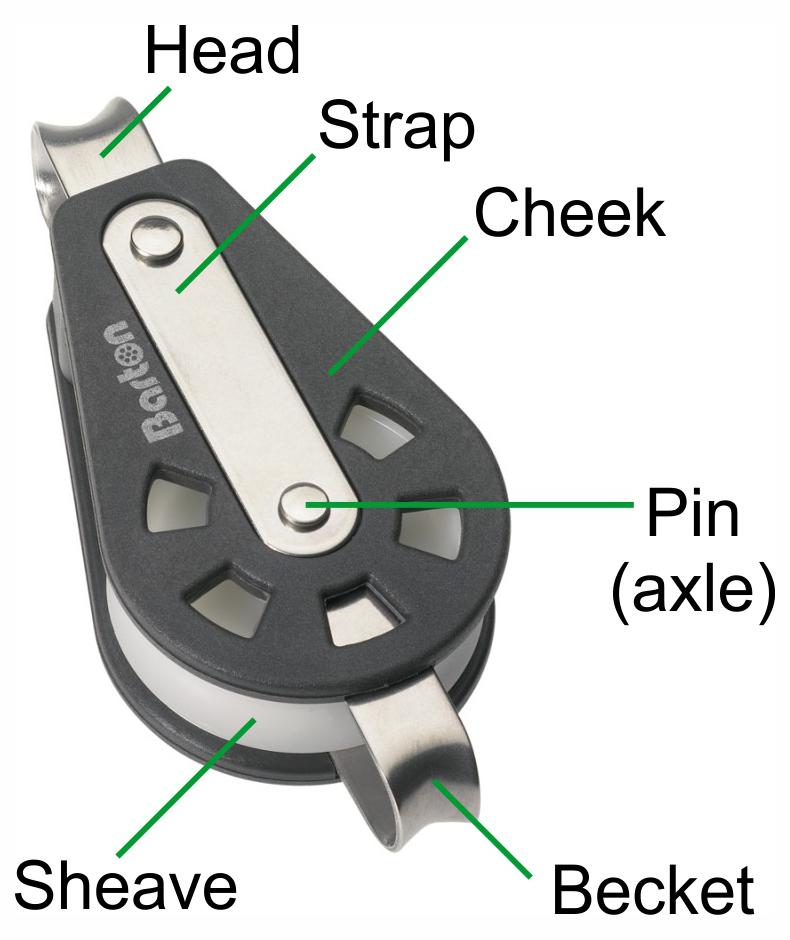

N.B. Plain bearing means that the sheave rotates directly on a simple central axle, i.e. the transverse pin between the cheeks of the block

N.B. the sheave (pulley wheel) may have a load-bearing bush, also known as a bushing or sleeve bearing.

A bush is added to reduce friction and resultant wear.

The bush that bears the load is the origin of the term Plain Bearing.

The picture shows a Barton plain bearing block, a sheave with a bush fitted and a sheave with no bush.

Plain bearing block features:

- No ball bearings, no roller bearings!

- Simple construction with only one moving part, the least possible to construct a serviceable pulley.

- Low maintenance

- The sheave rotates directly on a simple axle pin, which may have a load-bearing bush - sheaves have a groove designed to accept rope or wire sympathetically and are machined from nylon, aluminium alloy, brass or similar materials.

- Cost-effective and reasonably priced compared with ball bearing or roller bearing blocks.

- Excellent for high static loads – blocks with bearings will run faster under light load and cope much better with fine-tuning adjustments under extreme load

- Excellent all-around, multi-purpose functionality

- Excellent working life – no bearings to be crushed and/or fall out

Blocks with rolling elements are an engineering development of the plain bearing block.

Ball Bearing Blocks

Ball Bearing Blocks are ideal for running rigging applications where the line needs to run smoothly through the system and where there is a need for constant fine-tuning adjustment of the line under load, e.g. dinghy sheets - release, pump, tension.

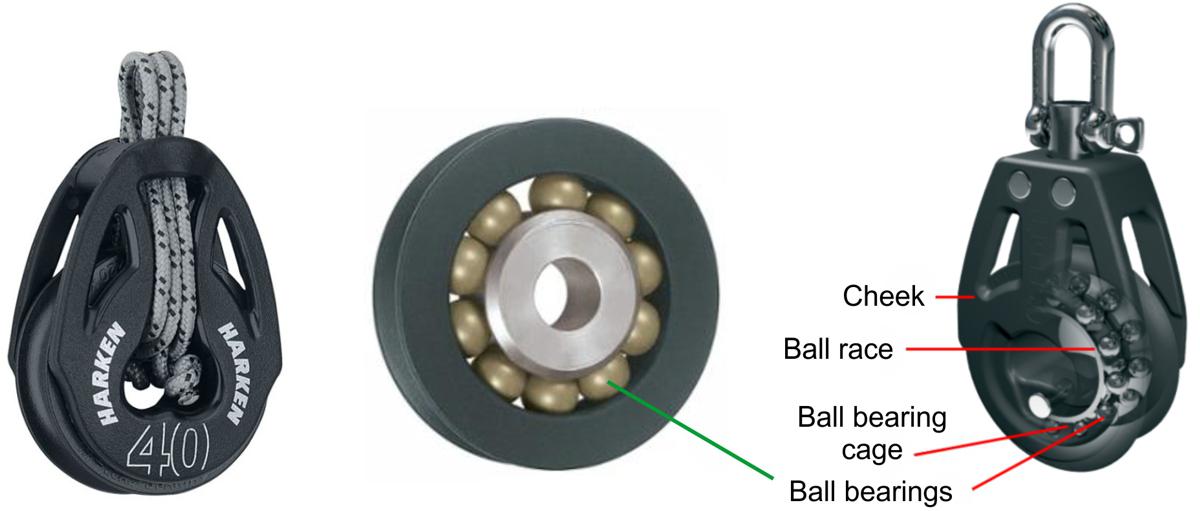

Ball Bearings in blocks are designed to rotate freely and can be identified by the distinctive whizzing sound they make when spun by hand under no load.

Ball Bearings are a set of multiple, relatively small in diameter, spherical balls encapsulated in a ball race or cage between the sheave and the rotating shaft.

The inner and outer ball races hold the balls captive and allow them to roll so freely that they are as close to frictionless as possible.

The hardened, round surfaces of the spherical balls can handle both radial and thrust loads.

The minimal contact surface area between the small spherical balls is the reason for their minimal resistance to movement.

However, because the load-bearing surface is also low, ball bearings are susceptible to distortion when subjected to heavy force.

The picture shows a Harken ball bearing block, a ball bearing and a Selden ball bearing block.

Ball bearing block features:

- Virtually frictionless sheave rotation for free-running lines

- Outstanding response under dynamic loads

- Ultimate performance functionality for Racing

- Suitable for rapid release and continual tuning

- Excellent durability with Torlon ball bearings

Roller Bearing Blocks

Roller Bearing Blocks are the 'Rolls Royce' premium choice for high load bearing capability and low resistance under dynamic load.

Go for roller bearings if you want exceptional performance for Racing, Regatta or Performance Cruising, especially for applications where it may be necessary to release or adjust a control line when under extreme tension.

Prompt, safe and uncomplicated manoeuvres can be more easily achieved if the control line can be fine-tuned or released under pressure, e.g. your running backstay/vang/kicker purchase, main sheet or spinnaker halyard.

Roller Bearings are a succession of small diameter tubes or cylinders fitted into a roller 'race or cage' between the sheave and the axle.

Roller bearings have a greater surface contact area than ball bearings.

The increased surface area increases the load capacity and distributes it more evenly, so that roller bearing blocks generally have a much higher resistance to distortion under load than ball bearing blocks.

Roller bearings don't run quite as freely as ball bearings, but they are exceptionally low-friction.

The picture shows a roller bearing on a sheave, an exploded diagram of a Harken roller bearing block and another design of roller bearing.

Roller bearing block features:

- Ultimate dynamic load capacity

- Premium Choice for severe conditions

- Excellent effectiveness under extreme static loads

- Outstanding response under acute dynamic loads

- Ultimate all-round, multi-purpose high performance functionality for Regatta sailing

- Excellent durability with Torlon roller bearings

Shop for Roller Bearing Blocks

Parts of a Yacht Rigging Block, traditional and modern