How to select Sheets and Guys

The Main Factors to consider in selecting your Sheets and Guys

The main criteria are Strength, Stretch, Durability, Heat and Abrasion Resistance, and Handling

Strength

Based on selecting the correct diameter for the application, all the sheets listed on our website should have the necessary break load.

LIROS publish a handy guide for establishing a benchmark diameter for each line by sail area: Recommended Line Diameters

There are two charts: Cruising and Racing.

For cruising yachts, 100% polyester lines should be suitable, but a Cruising Dyneema core will deliver a higher break load and reduce the strain compared with the applied tension.

For example, a large overlapping Genoa controlled by 14mm or even 16mm 100% polyester sheets could be substituted by a 12mm Cruising Dyneema without reducing the ratio of rigging strain to rope strength.

Upgrading from a 12mm 100% polyester to a 12mm cruising Dyneema line will significantly lessen the strain relative to the rated break load resulting in a better safety factor.

Lowering this ratio should help to lessen any stress on the fibres and extend the working life of the line.

Mainsheets typically have a purchase system which shares the load between all the lines. 4:1 is quite a common arrangement and divides the load by 4.

A 4:1 is a simple system, e.g. a fiddle (two sheaves) block and a fiddle block with becket (for attaching the end of the line) and cam (jamming cleat)

Remember that the blocks and their attachment points must be strong enough to take the total undivided force.

To achieve the higher break load required to withstand the associated extra strain, racing yachts should consider a full-specification Racing Dyneema line.

Stretch

100% polyester should be suitable for most cruising sheets.

Lower stretch ropes transfer the wind force to the rig more efficiently, getting the most out of each gust.

For cruising purposes, a little give in the system will dampen those forces, reducing the stress on all the rigging without unduly affecting progress.

Racing yachts will benefit from the lower stretch provided by a full-specification Dyneema line.

Durability

All rope fibres suffer from UV degradation when exposed to hot sun for prolonged periods. The rate of decline depends on the outer surface fibres of the rope you select.

Fortunately, the two most popular fibres, Polyester and Dyneema, both naturally resist the sun’s harmful rays. LIROS and Marlow Dyneema are impregnated with a polyurethane coating as part of the manufacturing process to increase that resistance.

UV deterioration should always be considered when purchasing ropes for use on yachts in tropical and subtropical climates.

Salt ingress can lead to harmful internal abrasion. Regularly rinsing the salt from your lines in freshwater will extend the working life of your rope.

Abrasion Resistance

Ropes naturally wear as they repeatedly pass through all the sheaves, blocks, and clutches that make up a working rig. Incorrectly specified and aligned routing will cause unnecessary wear. Contact with the deck or extraneous hardware as they move through the system will cause avoidable chafing, scuffing, or snagging.

Anti-chafe properties are based on the natural resistance of the fibres, the twisting process that creates the strands, and the tightness of the weave on the finished rope.

Polyester and Dyneema fibres are naturally endowed with the properties required for working a yacht rig.

A compact, consolidated braid improves abrasion resistance and significantly diminishes the chances of snagging and tearing; for example, 32plait will be preferable to 8plait.

A 32plait cover over a 12 strand Dyneema core will have better chafe resistance than a 12 strand 100% Dyneema hollowbraid.

Technora has superb cut resistance. LIROS and Marlow blend Polyester and Technora, combining their merits to create enhanced chafe-resisting properties.

Heat Resistance

Lines generate considerable heat when they are working around a winch.

Polyester has a relatively high melting point compared with polypropylene, nylon Dyneema and Vectran, making it suitable for most cruising sheets.

Technora has an extremely high charring temperature (it doesn’t melt at all)

LIROS and Marlow blend polyester with Technora (Aramid) to create a heat-resistant cover designed to withstand the rigours of intensive racing practices.

Comfort and Handling

The diameter makes a difference - crew with delicate hands will not enjoy trying to haul on lines that are too thin, and equally, they will struggle if the lines are too big to grasp and manhandle easily. Select a comfortable size in the hand where possible – 8mm-14mm will be the kindest.

The finish can be engineered to create a softer feel, e.g. the spun polyester yarn used to produce LIROS Mat Plait Polyester, or a bright smooth finish, e.g. LIROS Braid on Braid EVO.

Rope manufacturers blend Technora or Vectran into the rope jacket to increase grip factor and abrasion resilience. By the same token, this makes the line coarser to handle.

Coiling and Hanking – Consistent, balanced braiding is the key to manufacturing a non-kinking line that will not twist itself into a snarl. All braided or plaited lines should naturally adopt a figure of eight shape when stowed in a hank. Introducing a twist by rolling your thumb over the line helps to maintain the correct form for a three strand rope, but it is the single most common cause of kinking in a braided rope.

It is worth noting that a closer weave yarn structure improves wear resistance, but by the same token, it will reduce flexibility.

Grip

A firm, round braid on braid construction will minimise any flattening effect when a line is working around winches under tension and will provide essential grip in clutches and jammers.

Technora (Aramid) has an outstanding Gip Factor.

Splicing - Why splice your sheets?

Knots reduce the strength of any rope by an alarming degree; this varies between ropes but can induce a severe weakening by as much as 50%. Splicing will retain approximately 85% of the rope strength and an even higher percentage than that for some ropes.

Splicing - Why whip the end of your sheets

A stitch and whipped end will prolong the working life of your sheets by binding the cover and the core together. This helps to equalise the tension in each part throughout the length of the line. Whipping is the most enduring method of preventing the end of a line from untidy fraying and disastrous unravelling.

The Jimmy Green Custom Build Splicing and Whipping Service

Why not ask the Jimmy Green Rigging Team to splice and whip your new lines for you? It is such a simple exercise to specify and order all your lines professionally finished on our website using our innovative, step by step Custom Build process.

Summary - the Selection Process:

- Do you need Cruising or Performance?

- Cruising includes 100% Polyester lines and Polyester Jacket with a Cruising Dyneema core

- Performance steps up to Polyester Jacket with a Racing core, Blended covers with a Racing core, and 100% Dyneema

- Select a line and check their Plus factors to see how they match your requirements Select the diameter Make your selection for length, colour, splicing, whipping and a shackle if required.

- Our website will update the specification and the price each time you alter a drop-down menu option

- Save your choices by adding the finished line to your basket

- You can give each line a name or add any special notes for yourself or the rigger

- You are ready to add another line or try a different rope option for comparison in your basket.

Cruising Sheets and their Star Qualities

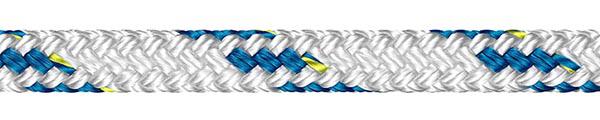

LIROS Braid on Braid EVO - Simply the Top All-Round Choice

- LIROS superb quality consistency

- Our customers’ most popular selection

- Most reasonable cost

- Optimal polyester solution for all running rigging

- Stretch at working load < 5%

LIROS Matt Plait - The Softer Handling Option

- Traditional spun yarn finish

- Comfortable grip in the hand

- LIROS superb quality consistency

- Available in white and various colours

- Stretch at working load < 6%

LIROS Top Grip - The New Generation Grippy Option

- Modern replacement for traditionally spun yarn

- Exceptional Grip

- Excellent Abrasion resistance

- LIROS superb quality consistency

- Stretch at working load < 5%

LIROS Herkules The logical LIROS Upgrade for Extended Cruising

- LIROS superb quality consistency

- Logical wear and heat resistance upgrade from EVO for extended cruising

- Optimal polyester solution for hard-working rigging

- Close weave, abrasion-resistant 1:1 plait spin-dyed polyester

- Stretch at working load < 5%

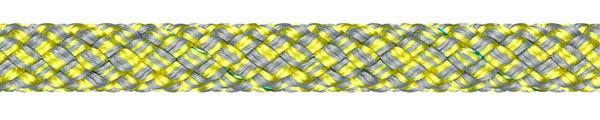

LIROS Dynamic Plus - The Top Cruising Dyneema Upgrade

- LIROS superb quality consistency

- The optimum Cruising Dyneema solution for hard-working rigging

- Superb uplift in performance due to Dyneema SK78 inner core

- Close weave, abrasion resistant 24/32plait spin-dyed polyester

- Stretch at working load < 2%

Marlowbraid - The Marlow Cruising Option

- Popular high-tenacity polyester solution for Marlow enthusiasts

- Stretch on a par with LIROS EVO due to loose lay core

- Downside - the tendency to flatten around winches and in clutches

- Stretch at working load c 4-5%

Marlow D2 Club - The Marlow Cruising Dyneema Upgrade

- Entry-level cruising Dyneema solution for Marlow enthusiasts

- Improved lower stretch due to coated Dyneema SK75 blended core

- Increased Break Load due to SK75 core content

- Stretch at working load c 2.5-3%

Marlow Blue Ocean - The Sustainable Choice

- The eco-friendly option

- Manufactured from 100% Rpet recycled polyester

- Yarn sourced entirely from waste plastic bottles

- Attractive marble effect blended colours

- Stretch at working load c 5%

Performance Sheets and their Star Qualities

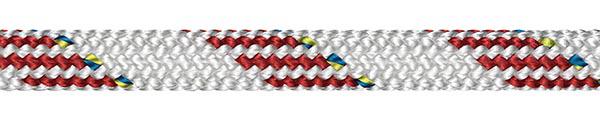

LIROS Racer - The Top Racing Option

- Stylish plain colours, no tracer yarn

- Optimum Racing Dyneema core solution

- Full capacity, coated heat-set Dyneema SK78 core

- Specially engineered 32plait polyester cover

- Stretch at working load < 1.5%

LIROS Control XTR - The Top Extreme Option

- LIROS XTR = the ultimate in extreme performance

- Super-pre stretched, coated, heat-set Dyneema SK99 core

- Specially engineered 32plait polyester/Technora blended cover

- Stretch at working load < 1.0%

Marlow D2 Racing - The Marlow Racing Option

- Racing Dyneema solution for Marlow enthusiasts

- 24plait polyester cover

- Full capacity coated Dyneema SK78 core

- Stretch at working load c 1.5%

Marlow D2 Grand Prix - The Marlow Top Performance Option

- Hard Racing Dyneema solution for Marlow enthusiasts

- 24plait polyester/Technora blended cover

- Super-pre stretched, coated Dyneema SK78 core

- Stretch at working load c 1.5%