How to Select a Suitable Halyard Rope

The main criteria are Stretch, Strength, Durability, Abrasion Resistance, and Handling.

Stretch comes first because what you feel is acceptable will determine the budget, or looking at it from the other way; your budget will determine how low a stretch line you can afford.

Stretch

There are two different types of stretch in a manufactured rope:

The natural extension of the fibre - Nylon, Polypropylene and Spun Polyester are naturally stretchy, while Dyneema and Vectran are not – High Tensile Monofilament Polyester can be engineered into a low-stretch rope. Manufacturers also use a heat setting process, further reducing the natural tendency to lengthen under load.

Constructional Extension – the structure of the strands or plaits will gradually settle into their elongated form after a bedding-in period – So, you should expect your new halyards to need ‘running in’ to achieve their optimal performance.

Will you be Cruising (including performance cruising) or Racing?

Regatta and Offshore Racing Skippers specify ultra-low stretch lines which will transfer wind velocity without dissipation in the search for boat speed, knowing that their racing rig is designed to withstand and utilise those forces.

Cruising Yacht Skippers should know that their cruising rig may not have been designed for extreme loads. Ameliorating the demands on the rigging will reduce the strain and extend the working life of all the integral parts. This should have the knock-on effect of lowering replacement frequency and cost.

Upwind Sails – Jib, Genoa, Main

Halyards for upwind sails (wind forward of the beam) should have the minimum stretch possible within your budget. Manage your expectations by judging how important sailing efficiency and a ship-shape rig are to you. Minimal extension is critical to achieving a tight luff (leading edge). Maintaining luff tension is crucial to sail shape and pointing performance.

If the line is not low stretch, it will eventually lengthen under load regardless of how hard you try when you first hoist the sail. The gradual lapse in tautness is generally known as sag. You can winch a line until it is bar tight, but if it isn’t a sufficiently low stretch line, it will eventually slacken, and you will need to apply more tension repeatedly.

Downwind Sails, including Reaching - Code Zero, Gennaker, Spinnaker

Stretch is not so critical in halyards for reaching sails (wind across the beam) and less important for downwind sails (wind aft of the beam) because they don’t rely on a bar-tight luff to achieve their design effectiveness.

A note on 2:1 Purchase Halyards

2:1 Pros

- Effective at reducing stretch and load on the line

- May allow a reduction in line diameter

2:1 Cons

- Increase in cost, the line will be 40%-50% longer

- The extra line will need to be managed at the mast base or in the cockpit

- The effort and time required to hoist the sail are significantly increased

Conclusion – a higher performance lower stretch line in a regular 1:1 system may represent better value

Strength

Sufficient strength is necessary, but most good-quality yachting ropes should have an adequate break load if you select the correct diameter.

For cruising yachts, 100% polyester lines should be suitable, but a Dyneema core will deliver a higher break load and reduce the strain compared with the applied strain.

Rope Manufacturers publish ultimate breaking point strains or guaranteed break loads but don’t generally refer to Safe Working Loads.

However, for any given force, a stronger line is subjected to a smaller percentage of the rated break load resulting in a better safety factor.

The advantage of reducing the rigging load proportionally is to lessen any stress on the fibres and extend a rope’s working life.

Upsizing a line to achieve a greater break load may be restricted by the size of the blocks, clutches, and organisers in your deck layout or on your mast. In this case, a higher specification rope with a polyester jacket over a Dyneema core or even a 100% Dyneema line may be highly beneficial, even on cruising yachts.

Durability

UV is the enemy. All rope fibres degrade when exposed to the sun for prolonged periods. The speed at which the deterioration occurs depends on the rope you select.

Happily, Polyester and Dyneema both have excellent natural resistance to the sun’s harmful rays. LIROS and Marlow also impregnate Dyneema with a polyurethane coating to enhance their resilience. Counteracting UV deterioration should be a significant consideration for yachts in the Mediterranean and the Tropics.

Abrasion Resistance

A working rig will continually cause natural wear on your lines. This includes all the sheaves, blocks, and clutches. Any rope routing system not specified and aligned correctly will induce unnecessary wear. Ropes that make any contact with the deck or extraneous hardware as they pass through the system will be subject to unnecessary damage from chafing, scuffing, or snagging.

Anti-chafe characteristics depend on the base filaments or yarns employed; the method used to twist the threads into strands, and the finished structure.

Polyester and Dyneema are naturally resilient to the effects of working a yacht rig, but a closer weave improves abrasion resistance and dramatically reduces the risk of snagging and tearing; for example, 32plait will be superior to 16plait.

A close weave jacket over a Dyneema core will be harder wearing than a 100% Dyneema 12-strand hollowbraid.

Salt ingress is inevitable and can lead to internal abrasion. Regularly washing your lines in fresh water to purge them of the salt will help to prolong a rope’s working life.

Comfort and Handling

The rope fibre, the finished structure construction, and the line diameter combine to determine how comfortable a line is to handle. Halyards are static for long periods, but when hoisted or dropped, there will be plenty of line to stow.

Coiling and Hanking - Balanced braiding is key to producing a non-kinking rope that won’t end in a snarl-up with repeated twisted looping. Braided and Plaited ropes should be allowed to fall naturally into a figure of eight in your hand to ensure that you are not introducing unwanted rotation into the rope, which will culminate in that dreaded twisted tangle you are trying to avoid.

It is worth noting that a closer weave yarn structure improves wear resistance, but by the same token, it will be less supple.

Clutches

A solid, round, and firm braid on braid construction will provide a good grip in clutches which is essential to prevent slippage.

Splicing - Why splice and whip your running rigging lines?

Knots reduce the strength of any rope by an alarming degree; this varies between ropes, but the weakening effect can be as severe as 50%.

Splicing will retain approximately 85% of the rope strength and an even higher percentage than that for many running rigging lines.

Whipping is crucial to match the tension of the cover to the core and to prevent fraying and unravelling.

Why take the risk when we can provide the service for you?

The Jimmy Green Custom Build Professional Finish Opportunity

Why do the splicing and whipping yourself when it is so easy to specify and order precisely what you want on our website using our innovative, step-by-step Custom Build process?

Summary - the Selection Process:

- Do you need Cruising or Performance – these are divided primarily by their stretch properties

Budget will be a significant factor in making this choice:

- Cruising includes 100% Polyester lines and Polyester Jacket with a Cruising Dyneema core

- Performance steps up to Polyester Jacket with a Racing SK78 core, Blended covers with a Racing SK99 core and a Vectran core option

- Select a line and check the Plus Factors in the category description to see whether they match your requirements

- Select the diameter

- Custom Build your line with length, colour, splicing, whipping and a shackle if required.

- You can alter any drop-down menu option, and our website will update the specification and the price.

- Save your choices by adding the line to your basket.

- You are ready to add another line or try a different rope option for comparison in your basket.

Cruising Halyards and their Star Qualities

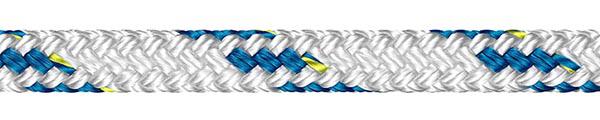

LIROS Braid on Braid EVO- Simply the Top All-Round Choice

- LIROS superb quality consistency

- Our customers’ most popular selection

- Most reasonable cost

- Optimal polyester solution for all running rigging

- Stretch at working load < 5%

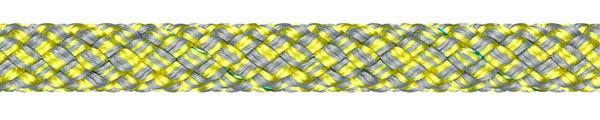

LIROS Herkules - The Serious Cruisers’ Upgrade

- LIROS superb quality consistency

- Logical wear and heat resistance upgrade from EVO for extended cruising

- Optimal polyester solution for hard-working rigging

- Close weave, abrasion-resistant 1:1 plait spin-dyed polyester

- Stretch at working load < 5%

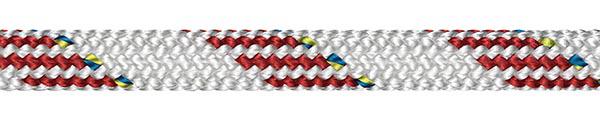

LIROS Dynamic Plus - The Top Cruising Dyneema Upgrade

- LIROS superb quality consistency

- The optimum Cruising Dyneema solution for hard-working rigging

- Superb uplift in performance due to Dyneema SK78 inner core

- Close weave, abrasion resistant 24/32plait spin-dyed polyester

- Stretch at working load < 2%

Marlowbraid - The Marlow Cruising Option

- Popular high-tenacity polyester solution for Marlow enthusiasts

- Stretch on a par with LIROS EVO due to loose lay core

- Downside - the tendency to flatten around winches and in clutches

- Stretch at working load c 4-5%

Marlow D2 Club - The Marlow Cruising Dyneema Upgrade

- Entry-level cruising Dyneema solution for Marlow enthusiasts

- Improved lower stretch due to coated Dyneema SK75 blended core

- Increased Break Load due to SK75 core content

- Stretch at working load c 2.5-3%

Marlow Blue Ocean - The Sustainable Choice

- The eco-friendly option

- Manufactured from 100% Rpet recycled polyester

- Yarn sourced entirely from waste plastic bottles

- Braid on Braid Construction

- Attractive marble effect blended colours

- Stretch at working load c 5%

LIROS Rope spliced to Wire - The Wire Option

- Traditional low-stretch halyard solution

- Excellent combination of LIROS polyester and stainless steel wire

- Spliced together by the Jimmy Green Rigging Team

Performance Halyards and Their Star Qualities

LIROS Regatta - The LIROS Performance Recommendation

- LIROS superb quality consistency

- LIROS optimum Regatta Performance Dyneema core solution

- Full capacity, coated, heat-set Dyneema SK78 core

- 30% enhanced abrasion resistance steel blue polyester cover

- Stretch at working load < 1.5%

LIROS Racer - The Top Racers’ Choice

- Stylish plain colours, no tracer yarn

- Optimum Racing Dyneema core solution

- Full capacity, coated heat-set Dyneema SK78 core

- Specially engineered 32plait polyester cover

- Stretch at working load < 1.5%

LIROS Control XTR - The Top Extreme Option

- LIROS XTR = the ultimate in extreme performance

- Super pre-stretched, coated, heat-set Dyneema SK99 core

- Specially engineered 32plait polyester/Technora blended cover

- Stretch at working load < 1.0%

LIROS V Force - The LIROS Vectran Performance Option

- Zero creep and minimal initial stretch

- Full capacity 100% Vectran core

- Specially engineered 32plait polyester cover

- Stretch at working load < 1.0%

Marlow D2 Racing - The Marlow Racing Option

- Racing Dyneema solution for Marlow enthusiasts

- 24plait polyester cover

- Full capacity coated Dyneema SK78 core

- Stretch at working load c 1.5%

Marlow D2 Grand Prix - The Marlow Top Performance Option

- Hard Racing Dyneema solution for Marlow enthusiasts

- 24plait polyester/Technora blended cover

- Super-pre stretched, coated Dyneema SK78 core

- Stretch at working load c 1.5%