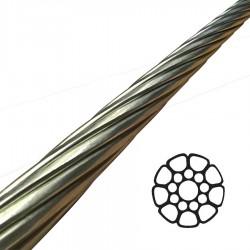

Compacted Strand stainless steel wire is designed for high-performance shrouds, backstays, and forestays on sailboats and yachts committed to racing or extended/performance cruising.

The compacted strand structure delivers lower stretch and higher break loads per diameter than standard 1x19 wire.

Compacted Strand was previously known as Dyform.

The increase in performance comfortably offsets the minimal weight increase.

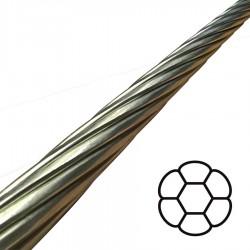

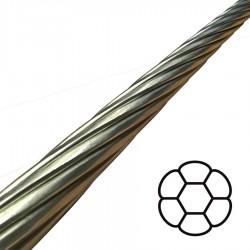

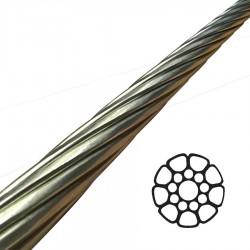

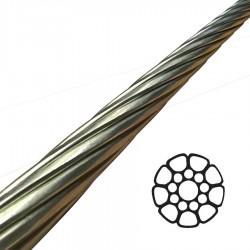

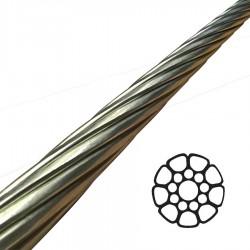

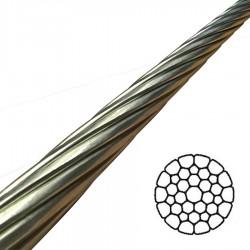

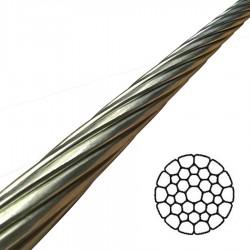

2.5mm, 3mm, and 4mm diameters are available in 1x7 construction ~ 5mm up to and including 12mm diameter is manufactured in 1x19 construction ~ 14mm diameter, and above is manufactured in 1x36

Jimmy Green Marine currently offer Compacted Strand wire from Petersen Stainless, hamma™ Pro Strand, and world leading wire manufacturer KOS = KOSFORM.

Jimmy Green Marine operate a strict accountability process for every reel of wire that the Jimmy Green Rigging Team use and record the corresponding batch number on every rigging order.

Traceability is an essential feature of the Jimmy Green assurance policy: Stainless Steel Wire - Quality Control and Care

You can be assured that your rigging will only be made up from top quality, fully accredited Compacted Stainless Wire.

All wire terminals are roller swaged onto the wire using Wiretechnik Roller Swaging Engineering Technology.

Roller Swaging is available in wire diameters from 2.5mm up to 16mm diameter (up to 12mm onsite). Assembly of finished wires 14mm and over is carried out at Sta-lok in the UK to JGM specifications using KOS wire.

WireTechnik are acknowledged throughout the marine industry as the leading manufacturer of top quality, reliable wire termination roller swaging machines.

Jimmy Green Marine offer the full range of Sta-Lok and Hamma Regatta swage terminals, e.g. eye, forks, tees, strap toggles, plus all manner of turnbuckle and backstay insulator options. Terminals from Petersen, Selden, Hasselfors, Bluewave, Navtec, and OS/BSI are also available.

Custom Build Wire Rigging Prices include swaging onto the wire. Custom Build Instructions

KOSFORM compact strand wire is now available. We are adding the option to our custom build system as the stock arrives. Email for more details if the diameter you require needs to be listed.

Compact Strand Facts, Features, and Plus Factors:

- 2.5mm, 3mm, and 4mm diameters = 1x7 construction

- 5mm up to and including 12mm diameter = 1x19 construction

- 14mm diameter and larger = 1x36 construction

- Compacting process makes it denser, heavier

- Sleek, uniform, burnished finish

- Superior corrosion resistance

- Appreciably stronger than standard 1x19 construction

- Increased strength means a greater safe working load factor - the load applied to the rig is a smaller percentage of the break load

- Lower stretch characteristic than standard 1x19 wire

- Compact Strand is generally acknowledged as a high performance rigging wire

- Pre-stressing is not required

How strong is Compact Stranded wire compared with KOS standard 1x19?

Manufacturer Minimum Break Load Comparison Chart for Stainless Steel Wire

| Wire Diameter |

2.5mm |

3mm |

4mm |

5mm |

6mm |

7mm |

8mm |

10mm |

12mm |

| KOS 1x19 |

500kg |

720kg |

1280kg |

2000kg |

2880kg |

3560kg |

4640kg |

7250kg |

10400kg |

| KOSFORM 1x7/1x19 |

690kg |

1000kg |

1780kg |

2440kg |

3550kg |

4910kg |

6150kg |

9770kg |

14400kg |

| Petersen Compact Strand |

690kg |

1000kg |

1780kg |

2600kg |

3600kg |

5000kg |

6300kg |

10000kg |

14500kg |

| hamma™ Pro Strand |

700kg |

1025kg |

1795kg |

2600kg |

3700kg |

5100kg |

6500kg |

10250kg |

14400kg |

MBL = Manufacturer Break Load

The strength information for KOSFORM is the minimum manufacturer-guaranteed break load, their actual break loads are higher, varying between 4% and 10% more according to the diameter.

How much stronger is Compact Stranded wire compared with KOS standard 1x19?

This Jimmy Green Chart expresses the increase in strength as an approximate percentage by diameter:

How much stronger is Compact Strand compared with Standard 1x19

| Wire Diameter |

2.5mm |

3mm |

4mm |

5mm |

6mm |

7mm |

8mm |

10mm |

12mm |

| |

40% |

42% |

40% |

30% |

29% |

43% |

40% |

41% |

38% |

How much less does Compact Stranded wire stretch compared with KOS standard 1x19?

How much less does Compact Strand stretch compared with Standard 1x19?

| Wire Diameter |

2.5mm |

3mm |

4mm |

5mm |

6mm |

7mm |

8mm |

10mm |

12mm |

|

22% |

22% |

23% |

19% |

20% |

16% |

23% |

19% |

20% |

How much heavier is Compact Stranded wire compared with KOS standard 1x19?

Weight Comparison for standard stainless steel 1x19 v Compact Strand (per 100 metres)

| Wire Diameter |

2.5mm |

3mm |

4mm |

5mm |

6mm |

7mm |

8mm |

10mm |

12mm |

| Standard 1x19 |

3.05kg |

4.49kg |

7.81kg |

12.2kg |

17.6kg |

23.9kg |

31.2kg |

48.8kg |

70.3kg |

| Compact Strand |

3.4kg |

4.9kg |

8.80kg |

13.5kg |

19.4kg |

26.0kg |

34.5kg |

54.0kg |

80.7kg |

The Jimmy Green chart below uses the same figures to express the weight as a percentage increase.

How much heavier is Compact Strand compared with Standard 1x19?

| Wire Diameter |

2.5mm |

3mm |

4mm |

5mm |

6mm |

7mm |

8mm |

10mm |

12mm |

|

11% |

9% |

13% |

11% |

10% |

9% |

11% |

11% |

15% |

Compacted Strand data is courtesy of Petersen Stainless.

For more in-depth information: Why choose Compacted Strand for your Standing Rigging

The Jimmy Green Rigging Team offer Compacted Strand Wire Rigging from these world-renowned Manufacturers:

Petersen Compacted Strand Stainless Steel Rigging Wire:

Manufactured in Europe from high quality European AISI 316 stainless steel grade 1.4401

Polished in the fully austentic condition to give maximum corrosion resistance

Dimensions and tensile grades conform to EN 12385 and EN 10264 - these stipulate tolerances on nominal diameter and minimum tensile strength for wire sizes.

hamma™ Pro Strand

The hamma™ brand is world renowned as a hallmark of quality for stainless steel rigging wire and components manufactured to withstand the rigours of modern-day yachting.

The hamma™ manufacturing facility is a state-of-the-art, modern factory located in Thailand with over 550 employees, including 60 highly skilled engineers who specialise in the design and production of marine tensile stainless steel solutions.

hamma™ Strand stainless steel wire rope is all produced under strict quality control procedures in accordance with ISO9001:2008 quality control, complemented by ISO17025 certification.

hamma™ Pro Strand manufacture includes a special strand compaction engineering process that decreases the constructional stretch of the wire and increases the break load capacity.

hamma™ technologically advanced production techniques ensure that there is no need to pre-stress the wire before use.

hamma™ Pro Strand Facts and Features:

- Compacted Strand 1x7 (up to 4mm) or 1x19 (5-12mm) construction

- c 30% higher break load than conventional 1x19 wire

- Lower stretch than standard 1x19 rigging wire

- Smooth, clean, aesthetically superior finish

- Pre-stressing is not required

hamma™ Regatta components are available to match the superior performance of the wire

Main Menu

Main Menu

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Main Menu

Back

Main Menu

Back

Back

Back

Back

Back

Back

Back

Back