Seldén Block Selection Guide

Choose the Right Block

All Seldén blocks are of the same superb quality and are the best for their particular application.

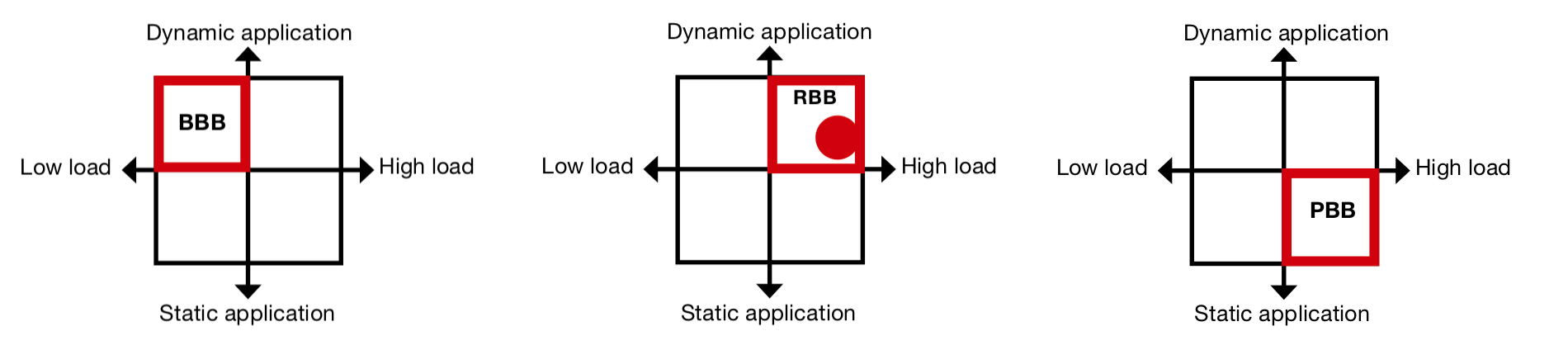

In order to make it easier to select the right block, they are categorised to suit four types of loads: low loads, high loads, static loads and dynamic loads.

Low Loads and High Loads

The practical difference between high loads and low loads depends on the amount of force you must exert to handle them.

The Selden definition sets the dividing line between high loads and low loads at 100 kg.

Even when the load is less than 100 kg, a normal person will require a mechanical system to deal with it, although the mechanical advantage may be relatively low.

A block and tackle with, e.g. a mechanical advantage of 4:1 converts a load of 100 kg into 25 kg, which can be managed by a single crew member.

Using a block and tackle with a mechanical advantage of 4:1 means that four times the length of line must be pulled.

In theory, this will take longer than it would take without any mechanical advantage.

The choice of mechanical advantage depends, therefore, on the load you feel able to manage and how quickly you want to do the job.

Static Loads and Dynamic Loads

Static Loads

A static load is one that does not cause the block sheave to spin. Typical static loads are found in halyard turning blocks where the sheave remains inert and under load for long periods of time.

Dynamic Loads

A dynamic load is one that causes the block sheave to spin. Typical dynamic loads are found in main sheeting systems, where the sheave spins frequently when sailing.

Breaking Loads and Safe Working Loads

Breaking Loads (BL)

Selden breaking load is the load at which any part of a block is caused to fail when subjected to increasing force during laboratory testing.

Safe Working Loads (SWL)

Selden safe working load is set at half the breaking load. Selden guarantee that blocks subjected to loads up to SWL will function satisfactorily.

Loads in the Specification Tables

The BL and SWL values shown in the block table are for the block itself (not for the line). The load exerted on a block depends on the load in the lines and on the deflection angle of the lines around the sheave.

Purchase System

A mechanical system can be used to increase the effect of human force required for a specific situation. Such systems are designed in several ways. A selection of typical mechanical systems are shown on the next page.

Seldén Designations

Seldén blocks are designated in accordance with two main features of the block. The first part of the designation specifies the type of bearing system or other special feature. The second part of the designation tells you the sheave diameter. For example, the PBB 60 is a Plain Bearing Block with a sheave diameter of 60 mm.

The Block Families

The blocks are divided into families. All the blocks in a specific family have the same sheave. The part numbers of the sheaves are the basis of the part numbers of the blocks. For example, the PBB 60 sheave is designated 406-001 and the PBB 60 single block is designated 406-001-01. The part numbers of the sheaves are stamped on the side of each sheave.