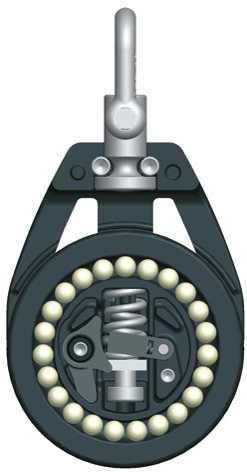

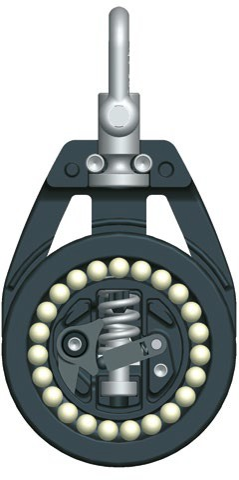

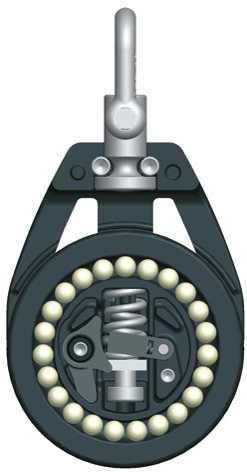

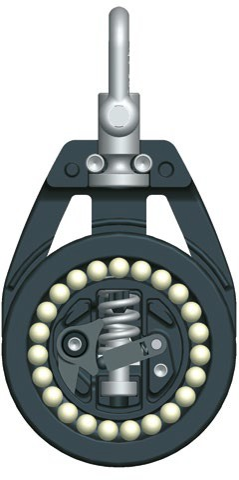

Ratchet Blocks are ball bearing blocks with an extra built in braking mechanism.

The sheave is designed to grip the line and allow the brake to take the load. The braking feature is a ratchet system which stops the sheave rotating.

The sheave design on a ratchet block is different to the smooth, rounded finish on a standard plain or roller bearing block. Ratchet sheaves are typically designed with eight-sided facets (they look a little bit like shallow gypsy wheel pockets). These facets (flat angled surfaces) grip the line when the ratchet is working under load.

The ratchet works like a socket wrench or the internal workings of a sheet winch. There are ratchet pawls which drop into teeth as the sheave rotates. This is what makes the distinctive clicking noise. When rotation is ceased, the ratchet pawl engages the aligned tooth and holds a share of the load using the friction created between the rope and the faceted sheave.

Ratchet blocks are aimed at making it easier for crew to haul in, hand hold and adjust lines while they are subjected to loads which would otherwise be impossible to physically manage. They also allow lines that are cleated under extreme tension to be eased, without jumping out and ripping through your hands as soon as the jammer is released.

On dinghies, dayboats and small yachts, ratchet blocks counteract the need for jamming cleats on jib, spinnaker and mainsheets, although a jammer may still be necessary to free your hands for e.g. adjusting control lines or giving your fingers a much needed rest ! On larger yachts, they offer extra control for trimming the spinnaker on a winch.

Ratchet Blocks are available in two distinct variations:

- Manual Ratchet Blocks feature a switch for on/off engagement - When the ratchet is on, the sheave will only operate in one direction, to pull the line in. The ratchet mechanism that takes the load prevents any rotation in the other direction, which means that when the line is eased, it will have to run around a static crenelated sheave.

- Automatic Ratchet Blocks are fitted with an automatic tension sensing mechanism which engages at a pre-set load and automatically releases when the line is eased. The roller bearings run freely in both directions under low loads and automatically engage as the pressure increases. Shifting between heavy and light loads is intuitive and seamless.

The Automatic version can change from ratchet assisted e.g. upwind jib and main, downwind spinnaker in moderate and stronger breezes to free spinning e.g. easing sheets during mark rounding, tacking and gybing. The pressure required to induce the autoratchet mechanism can be adjusted according to the strength of both the crew and the breeze using an allen key.

Ratchet blocks are, in effect a miniature version of a winch without a winch handle (also known as a snubber) and can perform a similar function within the limits presented by a much smaller surface area due to the narrower diameter.

Some class rules outlaw any mechanical advantage for pulling in the sheets which prevents the use of winches e.g. Beer Luggers where there is a great onus on ratchet blocks and/or snubbers to enable the crew to haul in, hold and control a loose footed mainsail of around 300 square feet by hand. Ratchet blocks require a fraction of the effort to control the sail compared with a normal free running block.

Ratchet blocks are generally suitable for sheets on boats up to and including 6 metre sports boats and on larger boats in tandem with a winch with some caveats (these are not exhaustive):

- Mainsheet systems need to be attached to the boom in multiple spots near the stern end (away from the gooseneck) to reduce/spread the load.

- Spinnaker sheets will require a winch back-up option if the breeze gets up.

- Jibs and Genoas generally don’t need ratchets. The shorter sheet lengths mean the sail can usually be secured in a cleat or around a winch before it becomes fully loaded

- Ratchet blocks can be mounted in series so that spinnaker sheets on e.g. Sports Boats like the Melges and J24s can be hand trimmed in all conditions. The holding power can be fine-tuned by engaging/disengaging the ratchets to match the breeze strength.

Line Diameter and Specification – Important Factors:

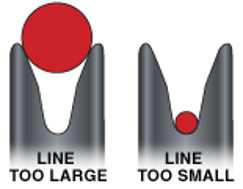

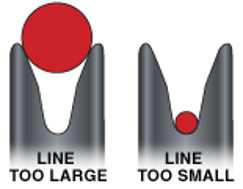

Match the size of the block (sheave diameter) to the required load, see illustration below:

Select the correct diameter line for the block because only a correctly matched diameter line will grip effectively in the flat facets on the sheave.

Select the appropriate rope finish - ropes with a smooth, hard feel will not hold as effectively as those with a more supple, pliable construction.

Select a line which will withstand the massive increase in wear and tear caused by continuous adjustment on the faceted sheave. This means that a regatta performance line will normally be required, preferably with Dyneema and/or Technora blended with polypropylene (lighter weight) or polyester (heavy duty).

Main Menu

Main Menu

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Main Menu

Back

Main Menu

Back

Back

Back

Back

Back

Back

Back

Back