The Jimmy Green Rigging Team can help you to determine the optimum specification if you are considering replacing stainless steel Guard Wires with Ultra-Performance, 12 strand Hollow-Braid, 100% Dyneema fibre rope or with a section of High Tenacity Webbing.

Fibre Guardrails

Dyneema Fibre Guard Rail Lines are spliced to length in the Jimmy Green Splicing Centre, the hub of our Custom Rigging Service operation.

Dyneema Guard Lines are available to order online in 5mm or 6mm diameter in a choice of ropes - LIROS D Pro Static or Hampidjan DynIce Dux.

Fibre Guard Lines may require one end to be spliced onboard so ensure you have the required fids and tools in your splicing kit to finish the job.

Ordering Fibre Guardrail Lines Online - the DIY finish on one end option:

- Select your preferred spliced option for one end - you may want to select the more difficult splice around a thimble/ring/terminator here

- Enter the required length - add a little extra for finishing the other end in situ.

- Leave the other end blank - as this will need to be spliced once the line has been passed through the stanchion holes.

If your stanchion holes are big enough for the Dyneema splice to pass through, then there are options for ordering both ends finished. The fattest part of the splice is at the throat where there is a whipping applied - the diameter of the splice in 5mm Dyneema will be approximately 8mm at this point and in 6mm it will be approximately 10mm. N.B. use a mousing line to pull the splice through the holes (don't push because it makes the rope bulkier)

Ordering Fibre Guardrail Lines Online - Both ends finished option:

- Select your preferred spliced option for one end - the most flexible arrangement is the long 'cow hitch' loop splice

- Enter the required length - make an allowance for adding your choice of fitting to the second end and making off with lanyards.

- Select your preferred spliced option for the other end - the most flexible arrangement is a repeat of the long 'cow hitch' loop splice

Webbing Guardrails

Webbing (wire replacement) Guardrails are produced to order, in house, by the Jimmy Green Sewing Team, on a state of the art, automatic profile, heavy-duty industrial Ultra-Sew machine using a tested and proven stitch pattern so you can rely on their strength and durability.

Webbing Guardrails in 45mm colourfast yellow or blue high tenacity, UK manufacture, UV stabilised 100% polyester webbing can provide a comfortable backrest.

Webbing Guard Rails are generallly fitted between two aft stanchions or between the aft stanchion and the pushpit i.e. in a short section that runs alongside the cockpit coaming.

Ordering Webbing Guard Rails Online:

- Select your sewing option - there are options for standard loop, lanyard (longer) loop, lanyard loop with spliced polyester lanyard, loop with S/S triangle.

- Select your preferred webbing colour and enter the required length.

- Select your sewing option for the other end.

Wire, Fibre and Webbing Strength Comparison:

4mm 1 x 19 stainless steel wire, KOS MBL = 1400kg, 5mm 1 x 19 stainless steel wire, KOS MBL = 2000kg, 6mm 1 x 19 stainless steel wire, KOS MBL = 2880kg

High Tenacity 45mm width Polyester Guard Rail Webbing, UK Manufacturer Break Load 3000kg

LIROS Break Load for D Pro Static - 5mm = 2450kg, 6mm = 4050kg, Hampidjan Break Load for DynIce Dux - 5mm = 4.8 tonnes, 6mm = 6.8 tonnes

N.B. All wire/rope splicing and sewing marginally reduces the breaking strain of the finished product.

Hampidjan publish a Spliced Break Load i.e. the strength of the line after it has been spliced.

DynIce Dux Spliced Break Load - 5mm = 4.3 tonnes, 6mm = 6.1 tonnes

Wire, Fibre and Webbing Stretch Comparison for the purpose of setting up Guardrails:

1x19 stainless steel wire - zero stretch

LIROS D Pro Static – Near zero elongation and creep

Hampidjan DynIce - Near zero constructional stretch and creep

High tenacity polyester webbing – 15% to 20% elongation at rupture suggests an estimated 2.5% stretch at the likely loads associated with breaking a fall - this equates to approximately 2 inches on a 2 metre section replaced by webbing between stanchions or between a stanchion and the pushpit rail

Jimmy Green Dyneema Fibre Rope Guard Rail Replacement:

All the fibre rope options are much stronger than 5mm wire and all the options (except for 5mm LIROS D Pro Static) are stronger than 6mm wire.

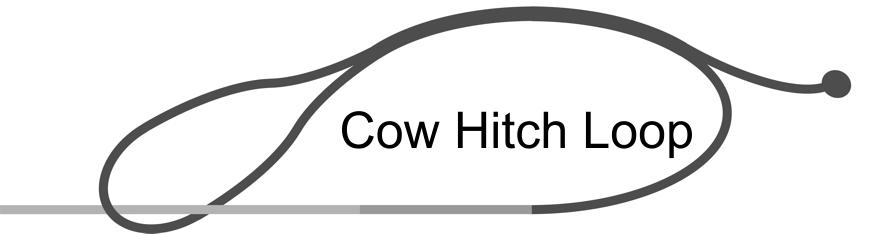

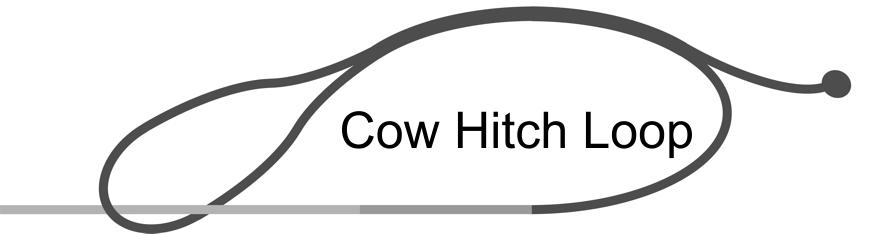

Cow Hitch Spliced Loops are extremely useful for attaching a line to an end fitting or to a fixed point - a cow hitch loop is a long soft loop spliced into the end of the line. The loop is approximately 75mm long when laid flat and pulled out straight. End Fitting - pass the long loop through the eye and over the top of the fitting to form a cow hitch on the eye. Fixed point - Pass the long loop around the fixed point e.g. a pushpit rail upright, thread the other end of the line into the long loop and pull the entire length of the line through until it is tight.

Aim to set up your lifelines so that the ropes have the maximum possible radius of turn around eyes/pins/fittings e.g. use a cow hitch loop around the pushpit tube (probably 25mm diameter stainless steel ) and through the connecting lug rather than directly on to the lug itself (probably more like 6mm diameter stainless steel)

Team Jimmy Green suggest that you regard 5mm DynIce Dux as the benchmark rope for fibre lifelines. D Pro Static is the LIROS top quality equivalent rope so makes a good alternative. Upgrade to 6mm if you prefer the belt and braces approach, although 6mm is generally only for larger yachts or for ocean going adventurers.

Fibre Rope options have minimal elongation compared with wire so they can be tensioned satisfactorily with lanyards. Team Jimmy Green suggest lanyards made from 3mm Dyneema with the commensurate number of passes to achieve a break load comparable with the static part.

Dyneema has excellent abrasion resistance but will be more prone to damage from unkind wear/snagging points than wire so it is extremely important to ensure that all stanchion holes and rail connecting lugs etc. are sympathetically smooth.

Anti-Chafe Sleeving provides excellent abrasion resistance in and around stanchion holes e.g. a short length of technora or Dyneema hollowbraid whipped securely into position or even a neat suede leather serving.

Dyneema can be visually monitored for signs of wear or other deterioration. Any damage can then easily be identified and addressed well before there is any chance of failure - Dyneema exhibits a loss of function by going fuzzy (or furry) but the deterioration from this point should be slow enough for it to be replaced in good time - prevention is better than cure.

Jimmy Green Webbing Guard Rail Replacement:

Webbing is stronger than 6mm wire.

Guardrail webbing sections are generally quite short at 2 metres or less and therefore, although webbing does have a certain amount of stretch (see above), tensioning by lanyards is still satisfactory.

Webbing Lanyards can be attached either directly to a soft stitched loop or to a stainless steel triangle sewn in to the loop.

Polyester Webbing can easily be checked for signs of damage, wear or deterioration. Any problems can be identified and sorted out at an early stage, well before the issue becomes critical - prevention is better than cure.

Guard Rail Lanyards

Guard Wires or their fibre/webbing replacement systems can be tensioned with lanyards. It is important to achieve a taut finish, but without over-tensioning as this may simply cause the stanchions to bend inboard.

Lanyards can be polyester, either e.g. LIROS Braided or LIROS 3-strand for spliceability.

High Calibre Lanyards with a specification more in keeping with your premium Dyneema lifelines are available in 12 strand, 100% Dyneema performance options. e.g. 3mm (for 5mm static part) or 4mm diameter (for 6mm static part) in:

LIROS D Pro LIROS D Pro XTR LIROS D Pro Static

Colligo Marine fittings will complete your Dyneema lashing installation with a stylish finish.

Using Colligo Marine Terminator® end fittings for DynIce Dux or LIROS D Pro Static Lifelines will achieve a large bending radius which will extend the working life of the rope.

Colligo Line Terminator end fittings allow for the use of stopper knots, which means that it is possible to lash to almost anything with ease.

e.g. Colligo CSS90 Male Distributor or Colligo CSS60 Female Distributor

Fit one of these two distributors, either male with a suitable shackle or female with a suitable pin to your existing installation e.g. the connecting lug on the pushpit

with e.g. a Colligo CSS70 Line Terminator spliced on to the end of the lifeline

Guard Rail Gates in Dyneema Fibre

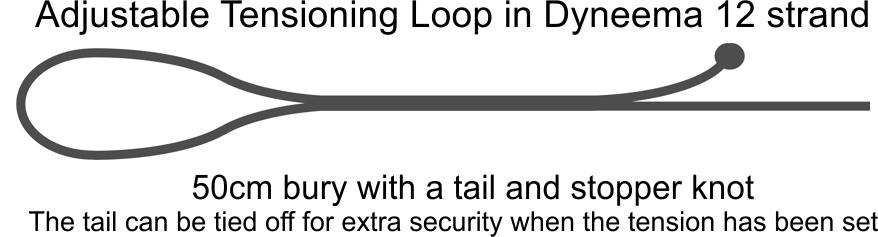

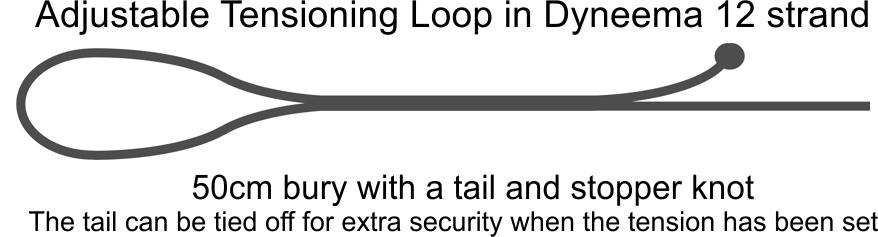

The combination of a Dyneema 12 strand tensioning loop with a cow hitch loop onto the Guardrail Gate Eye fitting (attachment lug), is a practicable solution to fitting fibre lifelines on guardrail gates. The other end can be cow hitched to a pelican hook or similar tensioning clip. Attach the pelican hook to the gate stanchion in the open position - tighten the loop and make off the tail - close the pelican hook to achieve the desired final tension between stanchion gates.

N.B. the tensioning loop is not a splice

Main Menu

Main Menu

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Main Menu

Back

Main Menu

Back

Back

Back

Back

Back

Back

Back

Back