Anchor to Chain Connection Guide

Look around any marina, harbour, or anchorage, and you will find various methods employed to join a yacht’s anchor to the anchor rode.

There is no right or wrong way to attach the two, but there are some general principles to follow, which should lead to a successful conclusion.

Applying the following principles to the decision-making process should lead to the optimum setup of any individual anchoring system.

How to choose the correct anchor shackles and connectors for your yacht or boat, and how to fit them together in the proper manner.

Galvanised or Stainless Steel Anchor Connections?

Generally speaking, avoiding contact between dissimilar metals is better because of the eventual corrosive reaction. Still, the widespread use of stainless steel connections on galvanised anchor systems indicates that the deterioration is either very slow or manageable.

Therefore, with the proper precautions, a combination of the two metals is acceptable where required - read more on Dissimilar Metals

The decision for stainless steel anchors and chain is relatively straightforward - use stainless steel fittings to join the two together. There is a wide range of different makes and models to suit all budgets - Purchase Anchor Connectors

For galvanised anchors and chain, a galvanised connection is a natural choice. However, the options available are realistically limited to shackles only - Purchase Anchoring Shackles

Galvanised Dee and Bow shape shackles generally feature a protruding head with a hole drilled through it for a. Tightening and b. Securing the PIN. It is worth noting that any protrusion may cause snagging or jamming through the stem head roller. Flush-fitting pins are mostly found on stainless steel shackles.

Correct Alignment of Load-Bearing Surfaces

Spread the load by matching the length and shape of the two bearing surfaces as closely as possible, e.g. a round pin in a snug round hole with both parts the same length. Avoid pinpoint loads.

The Importance of Providing Articulation

There is always the possibility of an ‘awkward’ force being exerted on the anchor shank and the connection to the anchor chain when the wind shifts or the tidal set reverses. The issue may be compounded when the anchor is retrieved, i.e. not a straight pull.

Therefore, the anchor connection must be capable of coping with a wrench from any direction.

Allowing or Encouraging Rotation

An anchor will not successfully dock into the stem head fitting if it is facing up the wrong way. An anchor swivel connector will allow the anchor to rotate as it approaches the bow roller. Some connectors are designed to actively twist or flip the anchor into the correct plane for re-entry.

Strength and Quality - Avoid any Weak Links in your Anchor Rode

Components that are rated with a manufacturer-minimum break load will provide reassurance. The integrity of any anchor system can be compromised by one weak link.

The working life of each part will depend on the quality of the base metal and the finish.

Steel should be a minimum grade 40 and treated with hot dip galvanising. N.B. Electroplating will not last very long in a marine environment.

Stainless steel should be a minimum grade 3 marine quality A316.

Examples of Good Practice for Joining Anchors to Chain

Alignment Considerations

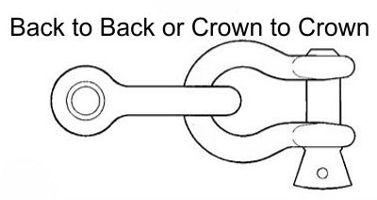

Couple two shackles together ‘back to back', i.e. with the two crowns bearing against one another.

Fit the largest diameter pin possible through the end link of the chain for the strongest possible joint.

Fit the largest, shortest pin possible through any ‘square cut’ hole, e.g. the slot in some anchor shanks.

Use the more open-rounded shape of bow shackles to allow more freedom of movement (articulation) where required.

Use D shackles to achieve a narrower fitting, especially those with a flush head to the pin.

You can take advantage of the oversized bow shackles that are factory fitted to some anchor brands, e.g. CQR. These shackles often feature a flush pin head with the thread permanently welded.

Unilateral Movement is Desirable

Fit a connector that provides for flip, twist, swivel, and articulation - all in one design, if possible, e.g. Ultra Flip Swivel

The Dee shackle in this example appears superfluous - this type of connector provides for rotation and lateral loading, but is not readily available with a manufacturer-guaranteed breaking strain.

This shackle is not correctly aligned on the anchor slot but is oversized to compensate and facilitates unilateral movement in the correct location. The Osculati Twist Connector has a long banana-shaped body to flip the anchor into the correct position for docking on the stem head and incorporates a swivel for rotation.

Introduce three anchor chain links between a standard swivel, e.g. a Kong design and the anchor. This ensures articulation between the anchor and the swivel, preventing lateral loading.

Buy 3 Links Of Anchor Chain

Use a Maillon Rapide (Chain Repair Link) - see Pros and Cons listed below the picture.

Pros: A good quality threaded chain repair link, e.g. Maillon Rapide link, can be as strong as the same size chain. This connection offers a streamlined attachment with no snagging and a sympathetic load-bearing surface to the end link in the chain or the anchor connector pin.

Cons: the thread may require a little filing to fit through a calibrated chain - it requires a thread-locking compound because seizing is impossible - in the picture above, it does not allow lateral movement on the anchor connector.

Examples of Bad Practice for Joining Anchors to Chain

Alignment Pitfalls

Joining shackles together ‘pin to pin’ will result in the bearing edges sliding from side to side.

Fitting the crown of a shackle through a ‘square cut’ hole so that the shackle bears on two unsympathetic stress points.

N.B. Any manufacturer-applied chamfering to the hole edges will mitigate the issue and fitting an extra strong, oversize shackle will also compensate.

Avoid Restricted Movement

Joining an anchor connector directly to the anchor shank with no freedom of lateral movement is not recommended.

This method is prevalent and looks very neat, but there is a strong possibility that, at some point, it will result in some damage or even failure when the anchor is trapped on the seabed.

Anchor connector with no apparent articulation

Anchor swivel connector with no articulation - the extra shackle on the chain seems superfluous.