Webbing Jackstays Guidance

Jackstays or Lifelines

Jackstays lay along the deck for you to clip onto with your harness safety line.

They can be made from rope, wire or webbing.

The reasoning behind Webbing

Webbing lies flat, so it is less obtrusive and kinder to your deck than wire.

Wire and rope tend to move or roll under your feet.

Wire can be PVC coated to prevent damage to your deck, but this increases the diameter and exacerbates the 'roll' problem.

The rope will need to be either more substantial in diameter or relatively 'high tech' to achieve the same breaking strain.

Jackstay Webbing strength compares favourably with wire.

Wire has the advantage regarding abrasion and UV resistance, although that does not apply to the PVC covering.

High Tenacity polyester webbing wears exceptionally well on deck, providing that you route the jackstays clear of any abrasive obstructions.

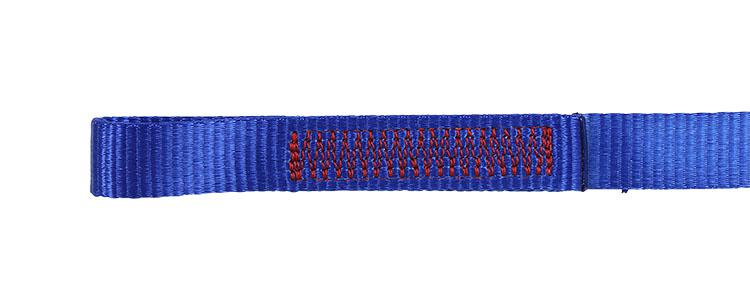

Jackstay webbing is manufactured from High Tenacity, High Denier Polyester.

Polyester has the highest natural resistance to the harmful effects of the sun's UV rays among all synthetic rope fibres.

How long will the webbing last?

UV Degradation

The enduring strength of the webbing depends on the length of time exposed to the sun and the strength of the sun's rays.

The reduction from the initial manufacturer-guaranteed break load will be gradual but relentless in the sunshine.

Removing them from the deck when the yacht is safely moored up will help preserve the working life.

It stands to reason that if the webbing is showing signs of degradation, the sewing thread used for the stitching will be in a similar condition.

Wear and Tear

Just like a polyester rope, if the webbing is damaged, the strength will be compromised. Some 'fluffing' of the surface fibres should be expected through natural wear and tear.

Replacement

Jackstay replacement is not predictable because it is based on variable factors.

There will be some clues.

Colour fades in the sun, which is a sure sign of deterioration.

Excessive abrasion should be visible and simple to check.

The condition of the stitching is integral to the strength of the sewn loop.

The bonded sewing thread will deteriorate at a similar rate to the webbing.

Ultimately, it is a matter for the owner to judge.

Strength Comparison

4mm 1 x 19 stainless steel wire, MBL = 1400kg

5mm 1 x 19 stainless steel wire, MBL = 2190kg

High Tenacity Polyester Jackstay Webbing, MBL = 2100kg or 3000kg

The majority of jackstays produced are from the 2100kg webbing, but we also supply stronger webbing, MBL 3000kg

N.B. All wire/rope splicing and sewing marginally reduces the breaking strain of the finished product.

Fitting Considerations

- Safe Attachment - The ability to clip on to the jackstay line while you are in the cockpit and still be able to venture as far forward (and aft) as possible without having to detach yourself is an important safety factor

This means that the jackstay line needs to 'overlap' the cockpit domain (it should at least run by the cockpit outside of the coaming so that you can reach it from inside the cockpit). It also needs to negotiate a path around or over the natural obstacles such as hatches, lower shrouds, grab rails, cleats, windlasses, bollards etc., so that the person clipped on to the jackstay line has a clear path to the forestay/pulpit (or pushpit) - Man Overboard Prevention - the path forward should be as near the centre line as practicable,

e.g. inside shrouds, over the cabin roof, but commonly found around the curve of the coachroof.

Clipping on to a jackstay that is too near the guardrail may result in you dangling in the water, especially if you are outside the leeward rail, with the yacht heeled, sailing upwind.

N.B. The MAIB Safety Bulletin 1/2018 has highlighted the importance of routing any jackstay or lifeline in such a way as to minimise the chances of a hook getting caught underneath any deck fitting and mooring cleats in particular.

"SAFETY LESSON - To prevent the strength of a safety harness tether from becoming compromised in service due to lateral loading on the tether hook, the method used to anchor the end of the tether to the vessel should be arranged to ensure that the tether hook cannot become entangled with deck fittings or other equipment."

Measuring your Jackstays

Jackstays should be fitted so that there is a degree of lift in the centre of the line before any significant load is applied.

The height of the lift should be

- proportional to the overall length of the jackstay

- dependent on the stretch of the jackstay

Webbing Jackstays have an element of stretch so they should be fitted taut to prevent too much slack when applying a bodyweight load.

Advisory: Webbing and Wire have Contrasting Stretch Characteristics

Webbing is in stark contrast to wire which, if fitted too tight, may cause excessive load on the end fittings when under load due to a 'bowsing' effect .

A tight wire jackstay may also make getting the safety hook under the wire difficult.

The Jimmy Green Sewing Team Finished Length Process for Webbing

Webbing has a degree of stretch even at low loads.

- Stitch one end

- Connect the stitched end to a shackle with a large, robust measuring tape attached, and lay the webbing out taut but not stretched along the floor/trough

- Identify and mark the turning point for the sewn loop at the other end of the webbing

- Complete the second stitched loop

- Check the finished length against your order

Taut, not Stretched, means snug so that the webbing is pulled out straight but not stretched tight with excessive force.

N.B.

The website will accept a length to 3 decimal points. However, this is not practicable for webbing.

The Jimmy Green Sewing Team can produce jackstay lengths to the nearest centimetre, i.e. to two decimal points.

However, because webbing has a degree of stretch at a relatively low load, Jimmy Green Marine can only accept responsibility for the final measurement as follows:

< 5 metres accuracy overall to the nearest 25mm.

> 5 metres accuracy overall to plus or minus 0.5%

e.g. 6 metres = 30mm, 8 metres = 40mm, 10 metres = 50mm

Selecting your fixing points

Jackstay strong points should be selected according to the principles listed above.

If there are no suitable fixing points in the right position, you may need to fit our Jackstay U Bolts

Sewn End Options

Standard Sewn Loops for attaching to shackles - the shackle is wide enough for the webbing to fit on the shackle pin.

Standard Sewn Loops with extra-wide shackle included.

Twisted Sewn Loops

These are for passing the other end around, e.g. a stanchion base and back through the twisted loop. This creates a 'cow hitch' finish, which means the loop will sit comfortably on the deck fitting. You will need to estimate the length required to go around the deck fitting.

Sewn Lanyard Loops

These are bigger loops to allow for multiple reeving of the lanyard.

Lanyard on Sewn Loops

These are bigger loops with a 2 metre spliced lanyard included.

Loop with Makefast Adjuster

30cm Loop (laid out flat) created by threading the webbing onto the locking part of a Makefast 3541 Jackstay Anchor and back through the Gate Adjuster with a 20cm heat-sealed tail

Sewn Loops with stainless steel ring - lanyards can be spliced onto the ring

Sewn Loops with stainless steel triangle - lanyards can be spliced onto the triangle.

Adjustment

Extra-wide shackles make a strong and secure fastening at one end, but achieving the right degree of tension with shackles at both ends may be difficult.

Lanyards at one end make the measuring, tensioning and fitting more straightforward.

Subtract around 200mm - 300mm from the overall length to facilitate the gap filled by the lanyard. The gap should be proportional to the overall length.

Lanyards are produced from 5mm LIROS Pre-stretched Polyester: manufacturer break load = 600daN = approximately 610kg.

The lanyard will require a minimum of four turns to ensure a comparable break load to the stitched webbing and the spliced rope.