Best Practice for Attaching Sheets to Sail and Deck Hardware

Whether cruising coastal waters or preparing for offshore conditions, securely attaching your sheets is fundamental for both safety and performance. Below, we break down the most effective methods for attaching sheets to the most common sail types. Attachment to the:

-

- - Headsail clew (Jib, Genoa, Staysail)

- - Lightweight Sail Clew (Spinnaker, Gennaker, Cruising Chute, Parasail)

- - Mainsail Boom and Deck (Top Block of the Purchase System)

1. Attaching Sheets to the Clew of a Headsail (Jib, Genoa, Staysail)

Headsail sheets must withstand significant loads, especially when beating or reaching with the wind forward of the beam. They are rarely changed once rigged, so quick release is not often required. Lightweight, soft solutions are preferred to reduce the danger associated with flogging sails when manoeuvring.

Common Practice:

- A bowline knot tied directly through the clew ring or eyelet. This remains the most widely used and trusted method due to its simplicity and convenience. Secure the knot with insulation or rigging tape to prevent it from shaking loose under flogging or luffing conditions. Finishing the sheet with a professional whipping will prevent fraying and extend the working life of the line.

- Cow-hitch the middle of a single length of line to the clew. This is a snag-free, compact and lightweight solution that won't come undone due to flogging. Remember that the line will need to be double the length of a single sheet to make a pair.

Upgrade Options:

- Dyneema Soft Shackles are an excellent low-weight, high-strength upgrade when used with soft eye splices. One soft shackle can usually accommodate both sheets. The reduced weight of the line used in a splice, combined with a soft shackle, results in a very lightweight, snag-free and secure solution, even when subjected to severe flogging.

- Dyneema Core Sheets offer increased tensile strength and lower stretch, allowing for downsizing in diameter for easier handling and winching on larger sails.

- Dog bones provide a lightweight attachment option that is both compact and strong. For extra security, push a loop of the line through the clew cringle and then pass the dogbone through this loop.

2. Attaching Sheets to the Clew of Lightweight Sails (Spinnaker, Gennaker, Cruising Chute, Parasail)

Lightweight and downwind sails require careful consideration for sheet attachment to protect delicate sailcloth while maintaining ease of deployment and control.

The goal is to use strong and reliable gear that won’t damage the sail during gybes or takedowns.

Flogging sails are still a danger to consider, although they are typically downwind of the deck or further away.

However, these lines often need to be released under tension to retrieve the sail, for example, during an emergency douse or gust-induced collapse.

Therefore, quick-release mechanisms need to be considered.

Preferred Methods:

- Top-Opening Snap Shackles: While heavier and more rigid, top-opening snap shackles offer a quick-release option under load. Basic versions are equipped with a pull-pin and can have lanyards attached for easier remote control. Choose smooth-edged, marine-grade versions to minimise sail abrasion.

- Trigger Latch Top-Opening Snap Shackles: Upgrading to shackles that can be released under exceptional high loads with the use of a fid is helpful with connections that are handled on deck.

- Quick-Release Snap Shackles: This is another high-load solution specifically designed for optimal release performance with a remote lanyard. Quick-Release versions are ideal for rapid manoeuvres involving multiple sheets and guys.

- Dog bones provide a lightweight attachment option that is both compact and easy to release for rapid sail changes. For extra security, push a loop of the line through the clew cringle and then pass the dogbone through this loop.

Alternative options:

- Dyneema Soft Shackles are lightweight, strong and sail-friendly: Ideal for modern sails with webbing clew loops. Soft Shackles eliminate metal-on-fabric contact and reduce the risk of flogging damage during handling, making them perfect for a strong asymmetric spinnaker solution.

- Cow Hitch (Lark’s Head): Simple and secure, a cow hitch arrangement is ideal for wrapping a continuous sheet around a clew webbing loop, making it suitable for dinghy and dayboat asymmetric spinnakers.

Best Practice Tips:

- When using snap shackles, regularly inspect them for corrosion and check that the pin is functioning correctly — they must release reliably even when loaded.

- Opt for professional loop splices on stainless fittings to minimise weight and optimise strength.

- Whip all sheet ends and label if necessary for quick deployment and sorting.

3. Attaching a Mainsheet to the Boom (Top Block of the Purchase System)

The mainsheet is usually part of a multiple-part purchase system.

The top of the system is commonly secured to a strong point, such as a fixed eye on the underside of the boom or a webbing strap wrapped around it.

Some set-ups, such as German and transom bridle systems, have multiple boom attachments to increase efficiency and handling of the highest sheet loads found on a yacht.

Systems are typically designed for permanent installation (centre cockpit fiddle systems sometimes have a quick release to stow them out of the way when the boat is not being sailed).

Top Block Attachment Options:

- Webbing Wrap Strap: A heavy-duty webbing loop passed around the boom and secured with stitching or Velcro Hook and Loop. This option prevents corrosion between dissimilar metals, spreads the load, and reduces boom twist.

- Stainless Boom Bale: Usually slotted into the boom section for maximum security. This is a reliable and robust method, but it involves a fixed protrusion that can be hazardous with uncontrolled boom movement.

- Lashing with Dyneema: Can be used in place of webbing, providing an excellent strength-to-weight ratio and minimal stretch.

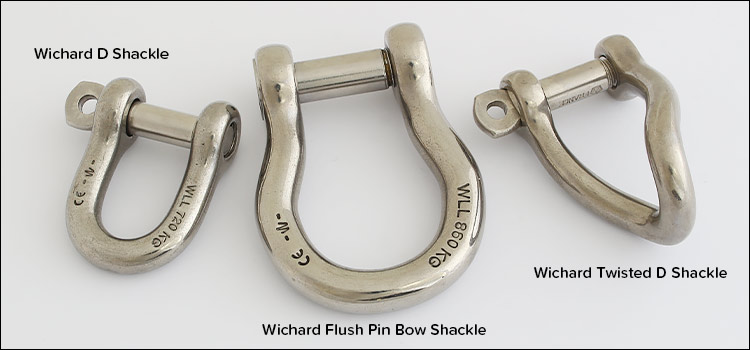

A strong bar shackle is usually preferred to connect the top turning block to these boom fittings.

Sheet Termination:

- A small loop eye splice is the neatest, load-efficient method for attaching the line to the block becket

- Whip the tail end of the sheet to prevent fraying, promote easier handling and prolong the life of the rope.

Final Recommendations

Bowlines, though universally trusted, must be secured — even a well-tied bowline can work loose if repeatedly flogged or vibrated. Taping the tail or tucking and seizing it with whipping twine adds a vital layer of security.

Whipping the line ends is more than cosmetic.

Whipping prevents the end from unravelling.

Whipping binds the core to the cover, preventing the line from wrinkling out of tension. The most common sign of this is a bumpiness in the rope that you can feel when you run your hands along it. This will have a deleterious effect on the rope's performance, leading to premature failure.

Without doubt, Whipping prolongs the working life of the line.

10 Good Reasons for Whipping Rope Ends

For superior durability, consider custom-spliced sheets tailored to your rig.

The Jimmy Green Rigging Team provides a professional Online Custom Build Splicing and Whipping Service, using top-quality lines from premium brands, LIROS Yacht Ropes and Marlow Ropes