Sta-Lok Rigging Terminal Fitting Instructions

5 easy steps to instant hand-fitted rigging, using Sta-Lok swageless terminals instead of hydraulic swaging

The Sta-Lok hand-fitting system is a simple mechanical method of terminating 1×19, 7×7, 7×19 and compacted strand wire ropes, in either right hand lay and left hand lay constructions.

Termination can be carried out on site or onboard using very simple hand tools, meaning no pre-measurement or site visit is necessary.

All Sta-Lok terminals are reusable*, requiring no servicing, providing long life and very low maintenance costs, manufactured from marine grade rust free 316 stainless steel.

*A new wedge component must be used.

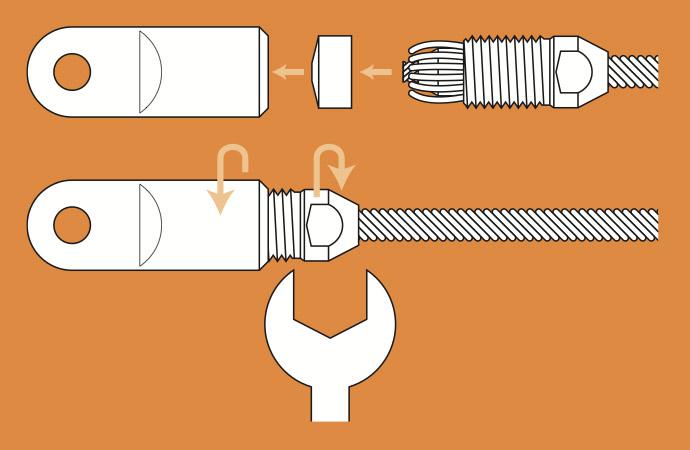

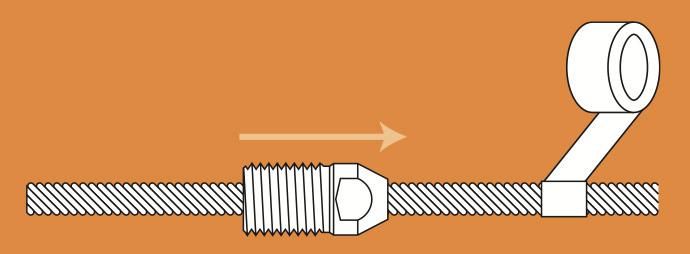

Step 1

Slide socket component over wire

Useful tip: Wind tape around wire approx 12” (300mm) from end. This will prevent the socket from sliding down the wire.

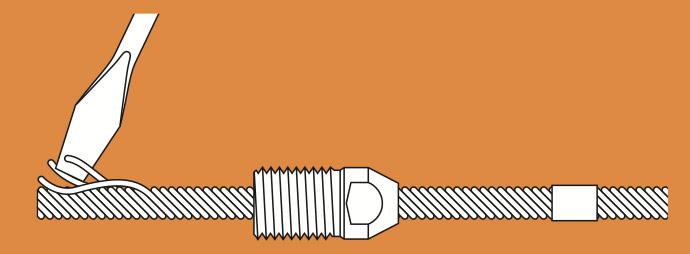

Step 2

Unravel outer strands 2" to 3" (50-76mm) to expose central core

Useful tip: Use a screwdriver to prise strands out of their natural position.

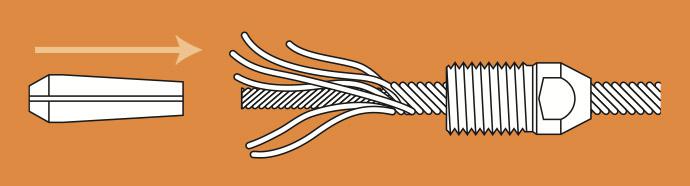

Step 3

Slide wedge component over central core of wire rope

Step 4

Reposition outer strands

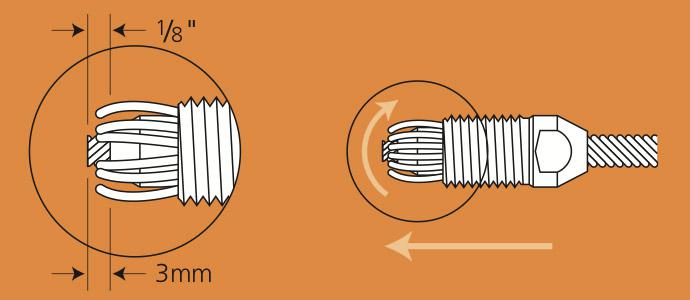

Turn outer strands either clockwise or anti-clockwise, depending on the lay of the wire, around the wedge.

Ensure approx 1/8” (2-3mm) of the central core protrudes from the end of the wedge.

Outer strands should be evenly arranged/separated around the wedge. Care should be taken to ensure that a strand does not slip into the slit of the wedge.

Useful tip: Push the socket towards the end of the wire while repositioning the outer strands to maintain control. When the wire strands are in position, push socket firmly as indicated to hold wires in position.

Step 5

Final Assembly

Ensure former component sits in bottom of end fitting.

Screw socket assembly into end fitting and tighten with spanners.

Sometimes there is a small amount of Tef Gel on the thread to prevent galling from the factory.

The fitting doesn't need anything to keep it together, however some people like to use a small amount of thread lock. If this is the case you need to fully remove any trace of the Tef Gel.

The assembly is now complete.

Useful tip: Undue force is not required to terminate the wire. Fitting instructions are supplied with each terminal.