Webbing Jackstays, Made to Measure

Professionally finished with heavy duty sewn loops to your individual measurements by the Jimmy Green Sewing Team.

Use the dropdown menu to custom build your Jackstay - WEBBING JACKSTAY GUIDE CUSTOM BUILD INSTRUCTIONS

More Information

Features

Accessories

Downloads

These are bespoke webbing jackstays made to your individual measurements. If you require a pair, please ensure that you add two to your basket.

Jimmy Green Advisory

The website will accept a length to 3 decimal points. However, this is not practicable for webbing.

The Jimmy Green Sewing Team can produce jackstay lengths to the nearest centimetre i.e. to two decimal points.

However, because webbing has a degree of stretch at relatively low load, Jimmy Green Marine can only accept responsibility for the final measurement as follows:

< 5 metres accuracy overall to the nearest 25mm.

> 5 metres accuracy overall to plus or minus 0.5%

e.g. 6 metres = 30mm, 8 metres = 40mm, 10 metres = 50mm

Webbing Jackstays, professionally finished with sewn loops to your measurements

Choice of 25mm high tenacity jackstay polyester webbing, manufactured in the UK.

Manufacturer break load 2100kg or 3000kg Custom Build Instructions

- High tenacity 25mm polyester webbing is ideal for webbing jackstays.

- High Tenacity polyester has excellent abrasion and UV resistance.

- UK Manufacture, MBL = 2100kg

- Available in Black, Blue, Red and Yellow.

- Previously used in the manufacture of Bluewater and Seago EN1095 Safety Lines.

Alternatively, you can select a stronger, slightly thicker webbing with the same width:

- High tenacity 25mm polyester webbing

- UK Manufacture, MBL = 3000kg

- Available in Plain White

Jimmy Green Webbing Jackstays are produced in house by the Jimmy Green Sewing Team on a modern, automatic profile, heavy-duty Ultra-Sew machine using a tested and proven, jig controlled stitch pattern so you can rely on their consistency, strength and durability.

All webbing jackstays are stitched with Nylbond 20, manufactured by the world's leading industrial thread manufacturers, Coats Threads

N.B. Webbing has a degree of stretch even at low load.

The Production Process:

We sew one end, connect it to a shackle with a measuring tape attached, lay it out taut but not stretched along the floor/trough, measure it to identify the turn in the webbing that will make the bearing edge, sew the second end.

In this way, we can produce jackstay lengths to the nearest centimetre i.e. to two decimal points.

However, we can only accept responsibility for the final measurement as follows:

< 5 metres accuracy overall to the nearest 25mm.

> 5 metres accuracy overall to plius or minus 0.5% e.g. 6m metres = 30mm, 8 metres = 40mm, 10 metres = 50mm

The 25mm webbing will fit comfortably onto the pin of our Extra Wide Stainless Steel Shackles.

We suggest you subtract a proportional allowance from the overall length when using lanyards to secure a jackstay end to the deck fitting e.g. a 20cm - 30cm (8'' - 10") gap

Twisted sewn loop - pass the other end around e.g. a stanchion base and back through the twisted loop. This creates a 'cow hitch' finish that means the loop will sit comfortably on the deck fitting. You will need to estimate the length required to go around the deck fitting

The Twisted loop will have an inside length of 100mm when laid flat unless otherwise requested.

We are happy to advise but we cannot determine the extra length required to allow for the size of your deck fitting.

We will produce the finished length to your specification.

Our Lanyards are 2 metres x 5mm 3-strand pre-stretched polyester spliced onto a 60mm sewn loop. They are available in Blue, Red or White The centre section will indicate your choice of colour. All the left and right end photos will appear in blue. Don't worry, the order will be as per the description.

5mm LIROS Prestretched Polyester manufacturer break load = 600daN = approximately 610kg. The lanyard will require a minimum 4 turns to ensure a comparable break load to the stitched webbing and the spliced rope.

What are Jackstays ?

Jackstays lay along the deck for you to clip onto with your harness safety line.

They can be made from rope, wire or webbing.

Why Webbing ?

Webbing lies flat so is less obtrusive and is kinder to your deck.

Wire and rope may tend to move or roll under your feet.

Wire can be PVC coated to prevent any damage to your deck but this increases the diameter and therefore exacerbates the 'roll' problem.

Rope will need to be either more substantial in diameter or relatively 'high tech' in order to achieve the same breaking strain.

Strength Comparison

4mm 1 x 19 stainless steel wire, MBL = 1400kg

5mm 1 x 19 stainless steel wire, MBL = 2000kg

High Tenacity Polyester Jackstay Webbing, MBL = 2000kg or 3000kg

The majority of the jackstays we produce are from the 2000kg webbing but we also supply stronger webbing, MBL 3000kg

N.B. All wire termination, rope splicing and sewing marginally reduces the breaking strain of the finished product.

Where should Jackstays be fitted ?

There are two main considerations:

- To be able to clip on to the jackstay line while you are in the cockpit and still be able to venture as far forward (and aft) as possible without having to detach yourself. This means that the jackstay line needs to 'overlap' the cockpit domain (it should at least run by the outside of the coaming so you can reach it from inside the cockpit) It also needs to negotiate a path around or over the natural obstacles such as hatches, lower shrouds, grab rails, cleats, windlasses, bollards etc. so that the person clipped on to the jackstay line has a clear path to the forestay/pulpit (or pushpit)

- To prevent Falling Overboard. This means that the path forward should be as near the centre line as practicable e.g. inside shrouds, over but commonly around the curve of the coachroof. Clipping on to a jackstay that is too near the guardrail may result in you dangling in the water, especially if you are outside the leeward rail with the yacht heeled going upwind.

Webbing and Wire Comparison

Webbing Jackstays are entirely different to wire:

- They are flat so they don't roll under your feet

- They are soft, so they don't 'catch' or mark the deck

- They stretch so you don't need to introduce any extra shock absorption

- Webbing that is fitted loose will allow too much slack when a bodyweight load is applied

Measuring your Webbing Jackstays

- Make them snug because they will stretch under load

- Do not stretch them tight because you need to allow enough room for clipping on without any delay or fuss

- Avoid any unnecessary slack to avoid a casualty falling too far

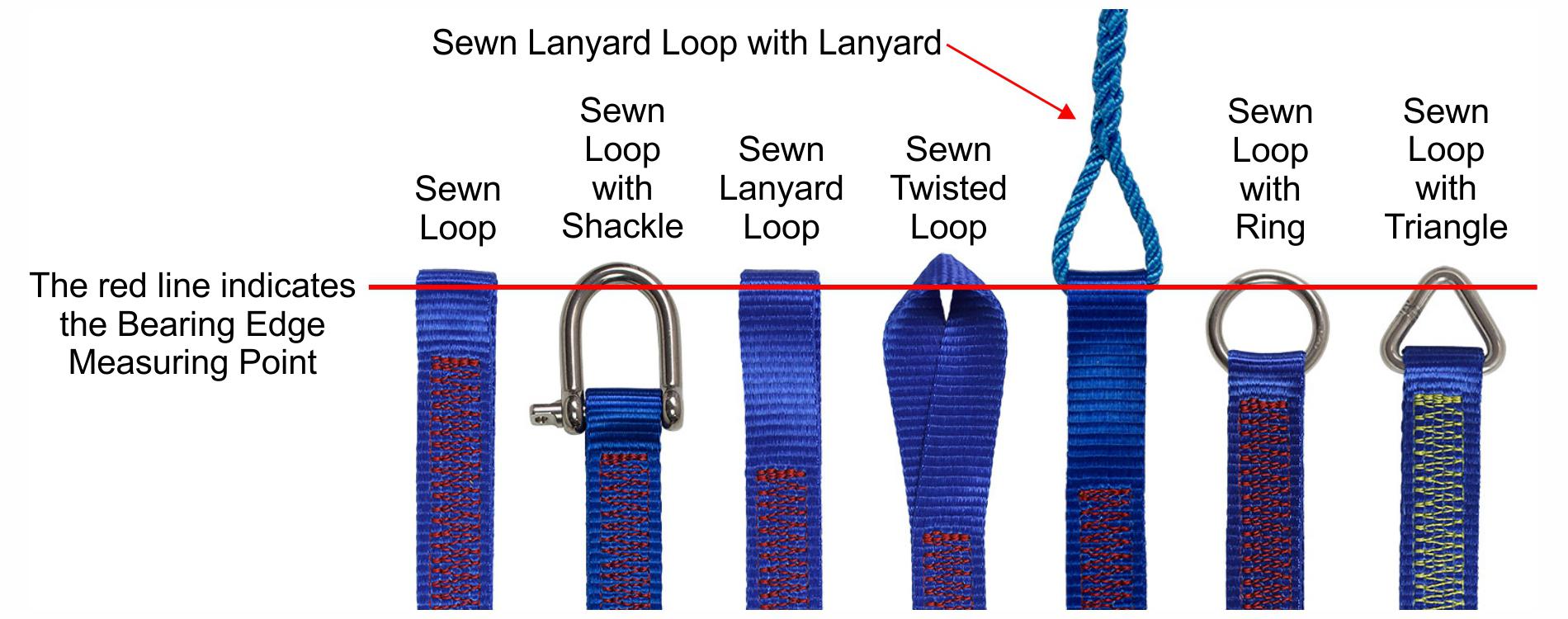

Measuring Points for Jackstays = the bearing edge:

All stitched loops including the twisted loop = the inside of the webbing loop that takes the load.

Makefast Adjuster Loop = the inside of the webbing loop

Extra-wide shackle, ring and triangle = the inside of the stainless steel that takes the load.

The bearing edge, measuring point is illustrated in the picture below.

Selecting your fixing points

Jackstay strong points should be selected according to the principles listed above.

if there are no suitable fixing points in the right position, you may need to fit new anchorage points.

These Wichard U Bolts, minimum 8mm, would be appropriate Jackstay U Bolts

End Options

- Standard Sewn Loops for attaching to shackles: we can supply extra wide stainless steel shackles. The shackle is wide enough for the webbing to fit on the shackle pin.

- Standard Sewn Loops with extra-wide shackle included.

- Twisted Sewn Loops - These are for passing the other end around e.g. a stanchion base and back through the twisted loop. This creates a 'cow hitch' finish that means the loop will sit comfortably on the deck fitting.

- Sewn Lanyard Loops - These are bigger loops to allow for multiple reeving of the lanyard.

- Lanyard on Sewn Loops - These are bigger loops with 2 metres spliced lanyard included to facilitate a lashing with a minimum 4 turns

- Sewn Loops with stainless steel ring - lanyards can be spliced onto the ring

- Sewn Loops with stainless steel triangle - lanyards can be spliced onto the triangle.

Extra-wide shackles make a strong and secure fastening at one end but it may be difficult to achieve the right degree of tension with shackles at both ends.

Lanyards at one end make the measuring, tensioning and fitting more straightforward.

Subtract approximately 200mm - 300mm from the overall length to facilitate the gap filled by the lanyard.

Nylbond Thread:

Coats Nylbond is a bonded nylon thread made from pre-stabilised continuous filament nylon 6.6. It cuts cleanly at thread trimming with no ply separation and provides superior abrasion resistance in the sewn product.

The high tenacity nylon allows for outstanding strength and durability. Its unique bond chemistry and proprietary coating technology produces a strong and supple thread with no ply untwisting, no flaking and no 'sewn in' colour change.

Nylbond is a specially formulated lubricant for high-temperature resistance and smooth operation through the needle eye without breaks, skips or staining. It has controlled stretch characteristics for good loop formation and tight, firm and balanced stitches.

Nylbond is certified to Öko-Tex Standard 100 and meets the Coats restricted substance list.

Nylbond 20 Specification:

Break Load = 9500 cN

Elongation % Min - Max = 17-29

Needle Size = 130-160 metric

- Purchase Type - Custom Build