-

Main Menu

-

Main Menu

-

-

-

-

-

Back

- How To Choose A Main Anchor

- Anchoring System Assessment

- Anchor Chain and Rope Size Guide

- The Jimmy Green Guide to the Best Anchor Ropes

- What Size Anchor Do I Need?

- Anchor to Chain Connection Guide

- How to Choose Your Anchor Chain

- How to Establish the Correct Anchor Chain Calibration?

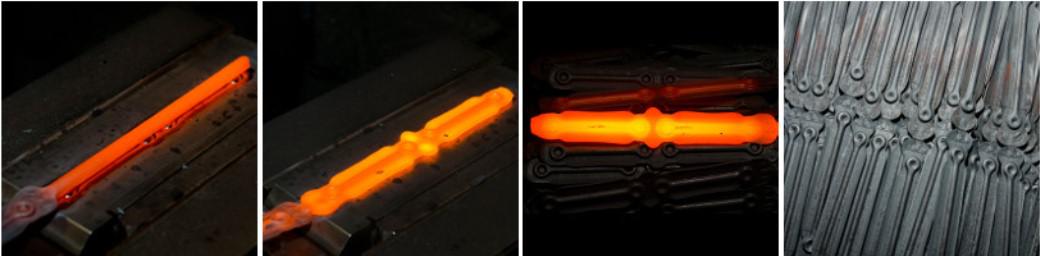

- Calibrated Anchor Chain - General Information

- Calibrated Anchor Chain Quality Control

- Calibrated Chain - Break Load and Weight Guide

- Galvanising - Managing Performance and Endurance expectation

- Can Galvanised Steel be used with Stainless Steel?

- Windlass Selection Guide

-

-

-

Main Menu

-

-

-

-

-

Back

- Replacing your Standing Rigging - a step by step guide

- Do it yourself Standing Rigging Quotes

- How to Identify and Specify Your Standing Rigging Components

- Sta-Lok Rigging Terminal Fitting Instructions

- Why choose Compacted Strand for your Standing Rigging

- Stainless Steel Wire - Quality Control and Care

- Stainless Steel Wire Break Load Comparison

- Replacing your Furling Line

- Fibre Rigging Break Load Comparison Guide

- A Guide to Inner Forestays

-

-

-

Main Menu

-

-

-

-

Back

-

-

Back

- Running Rigging Rope Fibres and Construction Explained

- How to Select a Suitable Halyard Rope

- How to select Sheets and Guys

- Dyneema Rope - Cruising and Racing Comparison

- Dinghy Rope Selection Guide

- Rope Measurement Information

- Running Rigging - LIROS Recommended Line Diameters

- Running Rigging Break Load Comparison Chart

- Colour Coding for Running Rigging

- Selecting the right type of block, plain, roller or ball bearing

- Replacing your Furling Line

- Recycling Rope

- Running Rigging Glossary

-

-

-

Main Menu

-

-

-

-

-

Back

- Blocks and Pulleys Selection Guide

- Barton High Load Eyes

- Dyneema Low Friction Rings Comparison

- Seldén Block Selection Guide

- Barton Track Selection Guide

- Barton Traveller Systems Selection Guide

- Harken Winch Selection Guide

- Karver Winch Comparison Chart

- Lewmar Winch Selection Guide - PDF

- Winch Servicing Guide

-

-

-

Main Menu

-

-

-

Back

-

-

-

-

-

Back

Flag Articles

- Flag Size Guide

- Bending and Hoisting Methods for Sailing Flags

- Courtesy Flags Identification, Labelling and Stowage

- Courtesy Flag Map

- Flag Etiquette and Information

- Glossary of Flag Terms and Parts of a Flag

- Making and Repairing Flags

- Signal Code Message Definitions

Other Chandlery Articles

-

-

-

Main Menu

-

-

-

-

-

Back

- Guard Wires - Inspection and Replacement Guidance

- Guard Wire Stud Terminal Dimensions

- Webbing Jackstays Guidance

- Webbing Jackstays - Custom Build Instructions

- Danbuoy Selection Guide

- Danbuoy Instructions - 3 piece Telescopic - Offshore

- Liferaft Selection Guide

- Liferaft Servicing

- Man Overboard Equipment - World Sailing Compliance

- Marine Safety Information Links

- Safety Marine Equipment List for UK Pleasure Vessels

-

-

-

Main Menu

-

-

Main Menu

-

-

-

C - F

Back

-

-

-

-

-

-

-

Main Menu

-

-

Back

-

-

-

Hidden

Back

-

Hidden

Back

-

Hidden

Back

-

Hidden

Back

-

Hidden

Back

-

Hidden

Back

-

Hidden

Back

-

-