More Information

Features

Accessories

Lewmar EVO® Self Tailing has been developed from the classic Lewmar Ocean Range.

The new EVO® specification benefits from all the Lewmar design and engineering experience which has been proven over decades of cruising and performance yachting.

The best marine specification alloys and metals are employed to deliver exceptional performance, reliability, longevity and strength to weight ratio.

EVO® Self Tailing Features:

- Hassle free servicing - no tools required, simply unscrew the top cap with your fingers to remove the drum and provide access to the gear train

- User friendly direction arrows

- Choice of three finishes - black or grey alloy and chrome bronze

- Manufacturer 7-year warranty

- size 15 = single speed, size 30 and above are two speed

- Convertible to electric (40ST and 45ST)

EVO® Self Tailing Plus Factors:

Wave Spring Jaw and Feeder Arm

The integrated investment-cast stainless steel feeder arm completely covers the top of the winch preventing the rope getting trapped and/or jammed above the wave spring jaws. The feeder arm can also be adjusted to smoothly feed the rope out of the jaws and into the cockpit.

Convertible to Electric

EVO® winches size 40ST and 45ST can be upgraded to work on electrical power by adding a Lewmar electric conversion kit and motor gearbox

Manufacturer 7-Year warranty

Lewmar are so confident about the quality of their new EVO winch range that they are backing their reputation with a new comprehensive 7-year warranty.

Lewmar Engineering Excellence

There is no such thing as “just a winch” for Lewmar because all the materials have been developed over many years, innovatively designed and precision machined using CNC* cutting edge equipment.

Lewmar engineering research and development optimises efficiency, durability, and strength to weight ratio.

* CNC stands for Computer Numerical Control – The movements of each machine in the manufacturing process are controlled, automated and monitored by the digitalised data in a CAM (computer aided manufacturing) software programme. CNC can be used to control a milling machine, lathe, router, welder, grinder, laser cutter, waterjet cutter, sheet metal stamping machine, robot and many other types of production plant.

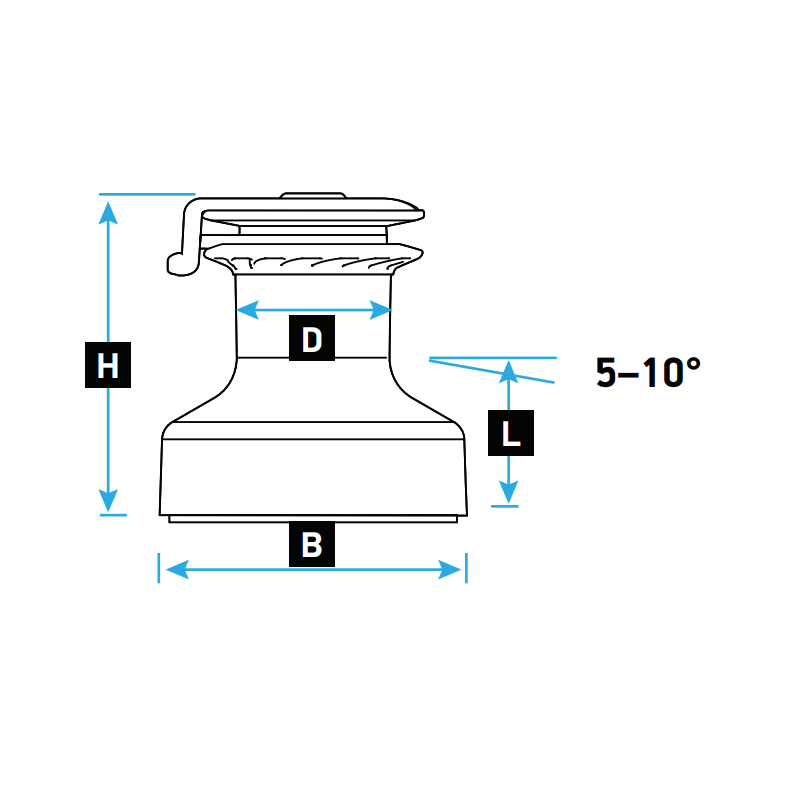

| Lewmar | Model Finish | Gear Ratio | Power Ratio | WLL | Weight | D Drum Dia | B Base Dia | H Height | L Line Entry | Line Size |

|---|---|---|---|---|---|---|---|---|---|---|

| L49515057 | 15ST Grey Alloy |

1st (2:1) |

1st (15.8:1) |

570kg | 2.6kg | 66.8mm | 121mm | 119mm | 58mm | 6-10mm |

| L49515055 | 15ST Black Alloy |

1st (2:1) |

1st (15.8:1) |

570kg | 2.6kg | 66.8mm | 121mm | 119mm | 58mm | 6-10mm |

| L49515056 | 15ST Chrome |

1st (2:1) |

1st (15.8:1) |

570kg | 3.9kg | 66.8mm | 121mm | 119mm | 58mm | 6-10mm |

| L49530057 | 30ST Grey Alloy |

1st (2:1) 2nd (4.2:1) |

1st (13.8:1) 2nd (29.2:1) |

685kg | 4kg | 74mm | 138mm | 145.5mm | 69mm | 8-12mm |

| L49530055 | 30ST Black Alloy |

1st (2:1) 2nd (4.2:1) |

1st (13.8:1) 2nd (29.2:1) |

685kg | 4kg | 74mm | 138mm | 145.5mm | 69mm | 8-12mm |

| L49530056 | 30ST Chrome |

1st (2:1) 2nd (4.2:1) |

1st (13.8:1) 2nd (29.2:1) |

685kg | 5.4kg | 74mm | 138mm | 145.5mm | 69mm | 8-12mm |

| L49540057 | 40ST Grey Alloy |

1st (1.9:1) 2nd (5.8:1) |

1st (13.2:1) 2nd (40.2:1) |

795kg | 4.9kg | 74mm | 148mm | 158.5mm | 79mm | 8-12mm |

| L49540055 | 40ST Black Alloy |

1st (1.9:1) 2nd (5.8:1) |

1st (13.2:1) 2nd (40.2:1) |

795kg | 4.9kg | 74mm | 148mm | 158.5mm | 79mm | 8-12mm |

| L49540056 | 40ST Chrome |

1st (1.9:1) 2nd (5.8:1) |

1st (13.2:1) 2nd (40.2:1) |

795kg | 6.5kg | 74mm | 148mm | 158.5mm | 79mm | 8-12mm |

| L49545057 | 45ST Grey Alloy |

1st (2.4:1) 2nd (7.6:1) |

1st (13.9:1) 2nd (44.8:1) |

1200kg | 7.1kg | 87mm | 168mm | 177.7mm | 84mm | 8-14mm |

| L49545055 | 45ST Black Alloy |

1st (2.4:1) 2nd (7.6:1 |

1st (13.9:1) 2nd (44.8:1) |

1200kg | 7.1kg | 87mm | 168mm | 177.7mm | 84mm | 8-14mm |

| L49545056 | 45ST Chrome |

1st (2.4:1) 2nd (7.6:1) |

1st (13.9:1) 2nd (44.8:1) |

1200kg | 9.7kg | 87mm | 168mm | 177.7mm | 84mm | 8-14mm |

Lewmar Winch Installation Advice:

Lewmar recommend that the winch is mounted on a flat surface and that the rope enters the drum at an angle of 5° to 10° to the base axis of the winch.

This angle can be achieved by using a base wedge when mounting the base plate.

- Finish - Chrome

- Finish - Grey Alloy

- Finish - Black Alloy

- Winch Type - Manual

- Winch Type - Self Tailing