In the field of seamanship, anchoring systems have evolved significantly, yet the practice of splicing a rope warp to chain remains a hallmark of safe and effective anchoring. This hybrid system—joining synthetic rope to a length of chain—blends flexibility and shock absorption with durability and holding power. This article explores the evolution of these systems, windlass compatibility, splice types and break strength considerations.

Historical Development

Anchor warps have come a long way from the days of basic three-strand matt nylon, once a mainstay for small boats due to its affordability and shock absorption. While easy to handle, this rope stiffened and weakened when wet. The introduction of heat-set nylon, with twisted strands thermally stabilised post-construction, marked a significant improvement in strength and abrasion resistance, making it suitable for larger yachts and more demanding conditions.

Later innovations, such as eight-strand heat-set lines like Anchorplait, further improved flexibility and spliceability. This balanced, colour-coded construction remained soft when wet and became a favourite for rope-chain tails, particularly in the popular 50:50 chain/rope setups of the 1980s and '90s. Configurations such as 30 metres of chain followed by 30 metres of warp offered excellent catenary with easier retrieval, especially important before electric windlasses became widespread.

Originally, rope and chain were connected with a thimble and shackle, but as windlass use increased from the late 1990s onward, more compact direct splices became necessary. These developments continue to inform modern anchoring practice, where strength, stretch and mechanical compatibility must be carefully balanced.

Windlass Compatibility

A key technical consideration in a rope-chain rode is its compatibility with the vessel’s windlass. Most modern windlasses feature a gypsy designed either for chain alone or a dual-purpose gypsy for both rope and chain. For smooth operation, the splice must pass seamlessly between rope and chain without catching or slipping.

Combination gypsies are profiled to grip chain links and the corresponding rope size. A poorly constructed splice can jam, slip, or cause premature wear. Correct tapering, tight weaving and proper sizing are essential for operational reliability.

Types of Rope-to-Chain Splices

Several technical splicing methods are used to integrate rope and chain, depending on the type of boat or yacht and the load requirements:

- Standard Tapered Splice: The most common method, where three-strand rope is unlaid, passed through the final chain link, and re-woven into itself. Tapering ensures smooth windlass passage and retains 80–90% of original strength.

- Long Chain Splice (3-strand only): This traditional technique passes two rope strands through the final chain link—one re-laid into the rope and one tucked. The resulting slim profile allows easy windlass handling and retains up to 94% of tensile strength. This is especially useful when matching high-tensile chain (e.g. G43, G70) with a suitable rope tail.

- 11-Link Splice: Here, the rope is woven through a nominal 11 consecutive links, distributing the load and reducing cyclic fatigue. Though bulkier, it improves performance in dynamic anchoring conditions and is common in offshore or high-load applications.

Break Strength and Testing

Splicing inherently reduces rope strength, making break strength testing essential for safety. Even well-executed splices can reduce tensile capacity by 10–30%. Although one should bear in mind that a knot has a far more detrimental effect on the strength of a rope.

The long chain splice for three strand, when properly done, shows excellent performance but is not currently offered by Jimmy Green in favour of the more popular butt splice.

The three strand butt splice is well known for its high performance.

Testing should focus on the two splicing options for Anchorplait to ascertain:

- Predictable performance: Knowing the minimum failure threshold ensures appropriate safety margins

- Material matching: High-strength chain must be paired with suitably rated rope and splices

- Confidence under load: Verified break load limits help sailors plan anchoring scope and contingency loads for weather changes or tidal shifts

Fatigue testing under cyclic loads is particularly important for extended anchoring or surge-prone areas.

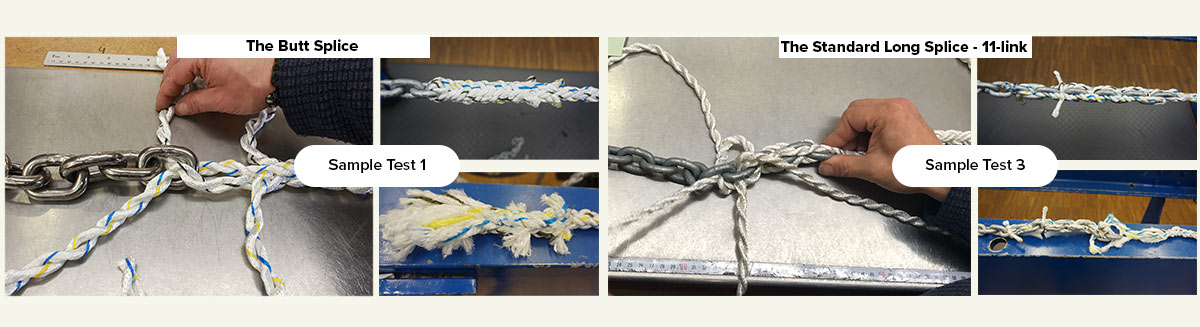

Comparative Splice Testing: Eight-Strand Nylon to Chain

With the rising popularity of Eight-Strand Nylon (e.g. Anchorplait) in rope-to-chain warps—especially on larger yachts equipped with powered windlasses—Jimmy Green Marine undertook a comparative test to evaluate the break strength of the two most widely used splicing methods: the end-link splice (butt splice) and the 11-link splice.

Test Setup

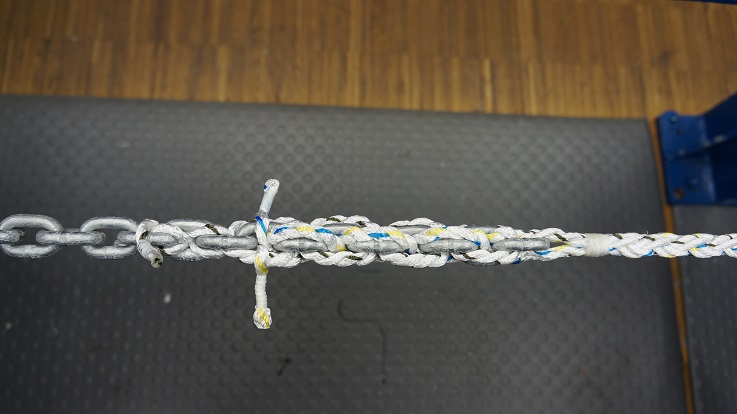

Multiple samples were produced in both configurations with variations to examine their reliability under load. The 11-link splice followed a traditional format: all strands passed through nine chain links, with a further two links used to create a tapered tail. Variants using 7, 11 and 15 links and differing whipping lengths on the tails were also tested.

The end-link splice was tested in two formats:

- A butt splice, where four strands were passed through the final chain link and tucked back without a crown knot.

- A soft eye splice, where the entire rope was looped through the final link and spliced conventionally.

Test Results

The results are shown below and referenced in the LIROS break test report here: LIROS Splice test Rope to Chain

| Grade 40 Chain Break Load 4000kg |

|

% Reduction |

| Anchorplait Nylon 14mm Break Load 4400kg |

Break Load |

Compared to BL |

| Sample |

Splice Type |

Kg |

Rope |

Chain 40 |

Chain 30 |

| 1 |

Butt Splice |

3108 |

29% |

22% |

-4% |

| 2 |

Soft eye splice |

2403 |

45% |

40% |

20% |

| 3 |

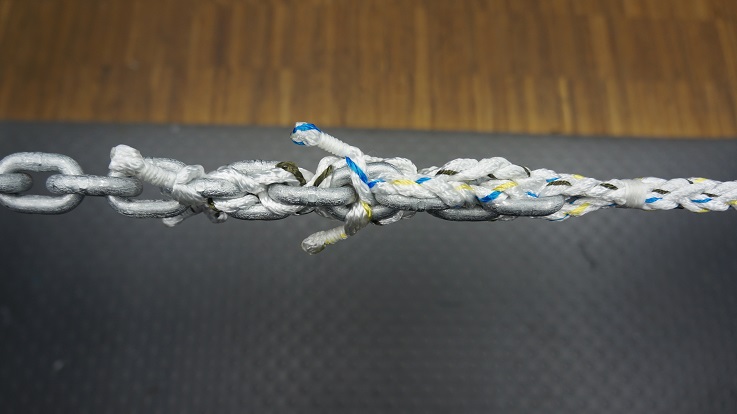

Standard long splice 11-link |

2434 |

45% |

39% |

19% |

| 4 |

Long splice 7-link |

2477 |

44% |

38% |

17% |

| 5 |

Long splice 15-link |

1769 |

60% |

56% |

41% |

| 6 |

Standard long splice 11-link - short whipping |

2803 |

36% |

30% |

7% |

| 7 |

Standard long splice 11-link - long whipping |

2567 |

42% |

36% |

14% |

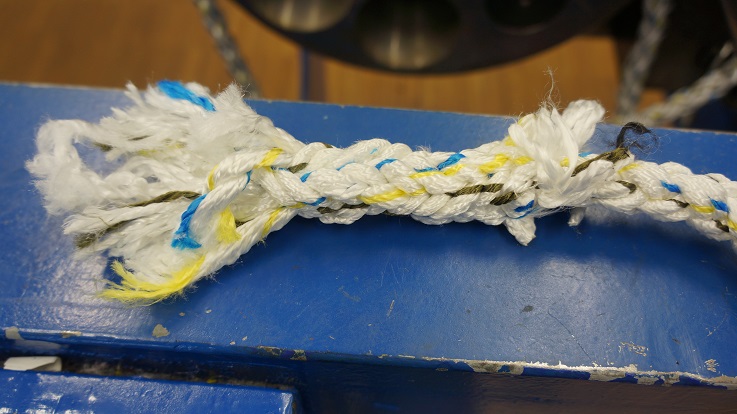

- The butt splice consistently outperformed the soft eye splice in terms of break strength. The likely explanation is the improved balance of loading: the individual passage of each strand through the chain link minimises stress concentration and ensures better load sharing.

- The soft eye splice, by contrast, forces all strands around a tight radius turn, creating excessive tension on the outermost fibres, likely leading to the earlier failure.

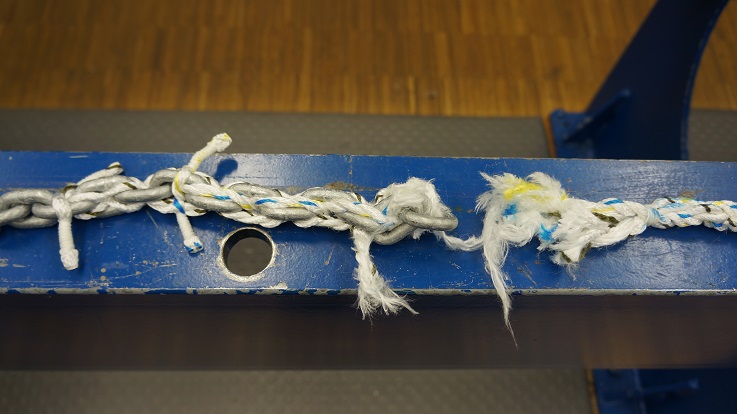

- Interestingly, the 15-link splice showed no improvement in strength over the 7- or 11-link versions. In fact, it was the only splice that didn’t entirely separate upon failure, suggesting that uneven tensioning of the strands through multiple links may have led to premature overload on a single pair. This indicates that increasing the number of links may introduce variability and a greater risk of human error.

- Whipping variations did not significantly affect the ultimate break strain. No failures initiated at or near the whipping in any sample, reinforcing that whipping length, while important for finish and handling, is not a critical factor in ultimate tensile strength.

Conclusion from Testing

For yachts using Grade 40 chain and higher-load anchoring systems, the butt splice is clearly the most reliable and mechanically efficient method for joining eight-strand nylon or three-strand rope to chain. As chain grades increase (e.g. from G30 to G40), so must the integrity of the splice to avoid creating a weak point.

In particular, when using 8mm Grade 40 chain with 14mm Anchorplait, consideration should be given to upsizing the warp to 16mm—provided the windlass gypsy can accommodate the larger diameter. This provides a closer match in tensile strength and improved safety margins.

The 11-link splice remains a valid option in non-windlass scenarios, such as for kedge anchors or warps, where extra weight and flexibility are beneficial. However, it is best suited to applications where precision splicing can be carried out consistently and where cyclic loads are moderate.

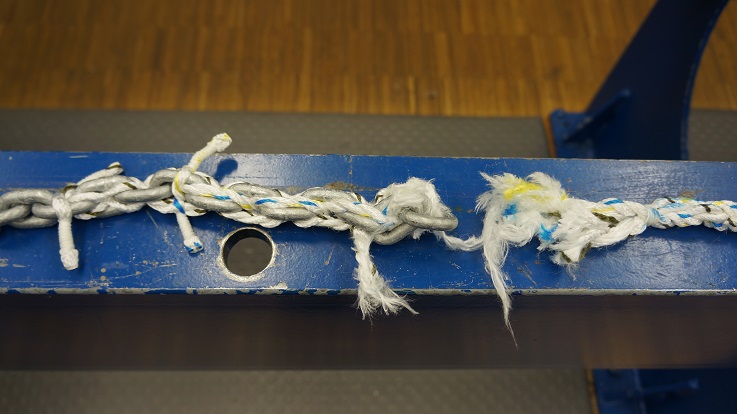

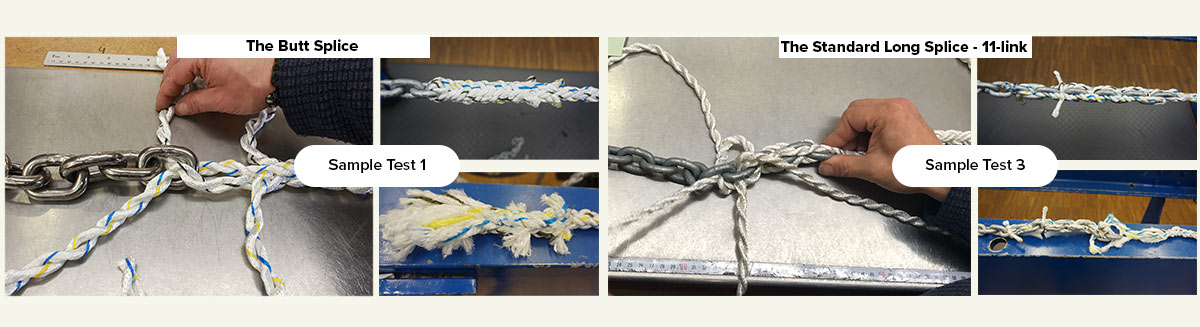

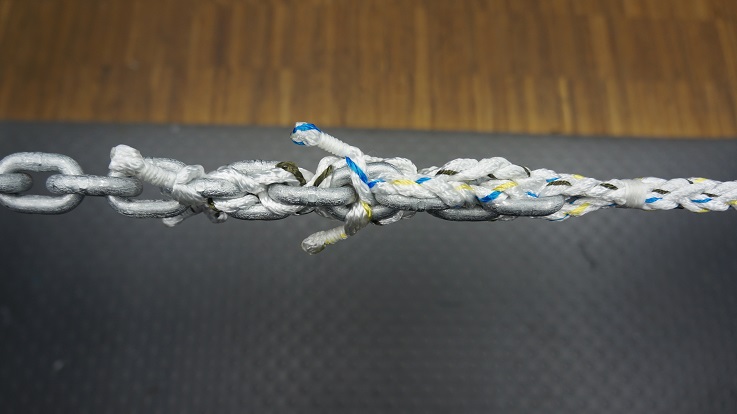

Sample 1: Butt Splice

Sample 1: Butt Splice after the test

Sample 2: Soft Eye Splice

Sample 2: Soft Eye Splice after the test

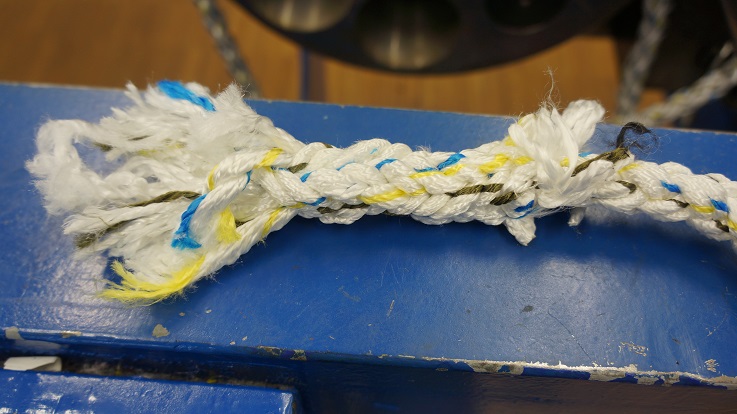

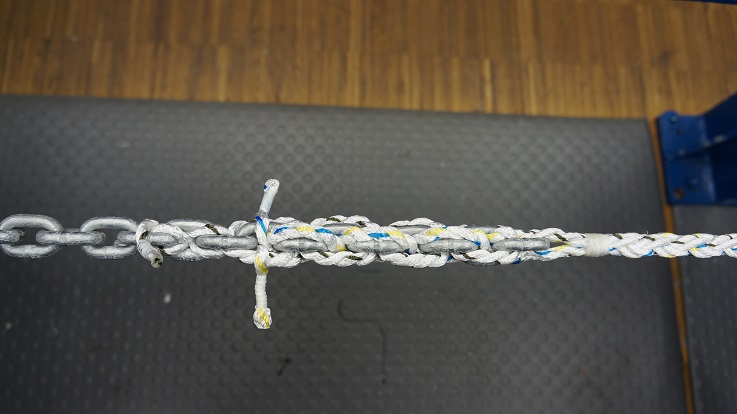

Sample 3: Standard Long Splice 11-link

Sample 3: Standard Long Splice 11-link after the test

Sample 4: Long Splice 7-link

Sample 4: Long Splice 7-link after the test

Sample 5: Long Splice 15-link

Sample 5: Long splice 15-link after the test

Sample 6: Standard Long Splice 11-link with Short Whipping

Sample 6: Standard Long Splice 11-link with Short Whipping after the test

Sample 7: Standard Long Splice 11-link with Long Whipping

Sample 7: Standard Long Splice 11-link with Long whipping after the test

Main Menu

Main Menu

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Main Menu

Back

Main Menu

Back

Back

Back

Back

Back

Back

Back

Back