3mm 1x7 Compacted Strand Stainless Steel Wire Rigging

Click on the boxes below to reveal your custom build options - Highlight your choice from the drop down menus

How to measure illustrations plus detailed Custom Build Instructions

More Information

Features

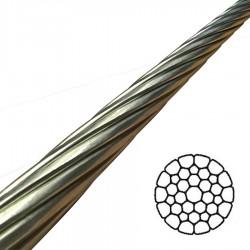

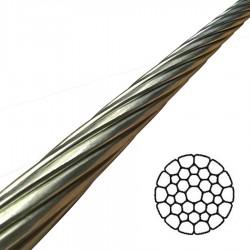

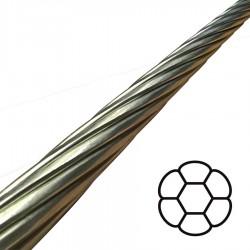

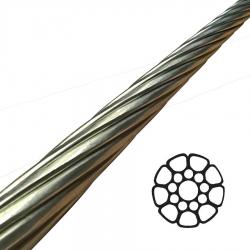

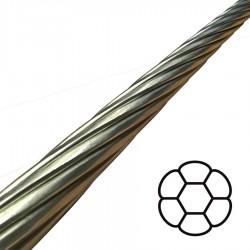

3mm 1x7 compacted strand stainless steel wire rope rigging produced to your specification using Kosform or hamma™ Pro Strand wire together with swage terminals from the world's most respected manufacturers, professionally terminated with meticulous care by the Jimmy Green Rigging Team.

Compacted Strand stainless steel wire is designed for high performance rigging - The dyform compaction process reduces stretch and increases break load by approximately 30% compared with standard 1x19 wire with only a minimal increase in weight per metre.

3mm 1x7 Compacted Strand Stainless Steel Wire Facts and Features:

Sourced from two world renowned manufacturers:

- Kosform Stainless, manufactured by KOS, the world's leading manufacturer for top quality stainless steel wire - 1.4401 polished wire in the fully austenitic condition to give maximum corrosion resistance - Manufacturer rated minimum break load 1000kg

- hamma™ Pro Strand, manufactured in a state-of-the-art, modern specialist factory located in Thailand under strict quality control procedures in accordance with ISO9001/ISO17025 - manufacturer rated minimum break load 1025kg

3mm 1x7 Compacted Strand - Talurit Termination Facts and Features:

- Sta-Lok British Standard copper ferrules

- Sta-Lok or hamma™ thimbles

- Performed with diligent application of manufacturer recommended practice

- Executed on a regularly serviced 20 tonne Cabco Talurit Hydraulic Press

3mm 1x7 Compacted Strand - Swage Termination Facts and Features:

- All terminals are manufactured from marine grade 316 stainless steel

- Top Manufacturer options: Sta-Lok, Petersen, OS/BSI, Bluewave, Crossbar, Hasselfors Seldén and hamma™

- Produced with meticulous care and attention to strict manufacturer tolerances

- Executed on an up-to-date, regularly serviced, electrically operated Wiretechnik Roller Swaging Hydraulic Press

The Jimmy Green Rigging Team have produced these guides to help you to identify your terminals and successfully tackle a complete overhaul of your standing rigging:

HOW TO IDENTIFY AND SPECIFY YOUR RIGGING

GUIDE TO TACKLING A COMPLETE RE-RIG

Quality Assurance

The Jimmy Green Rigging Team undertake to check the wire and the terminals during the production process to ensure that they are all 100% First Quality.

Jimmy Green Marine adhere to a thorough accountability and traceability process for all the wire and terminals used to produce your wire rigging.

All rigging work is performed with diligent care and attention to detail on our premises in Beer by Jimmy Green trained riggers.

- Purchase Type - Custom Build

- Stay Diameter - 3mm