The winter season has a habit of affecting the quality of your mooring kit, whether you have wintered on the hard or not. So what should you look out for before your spring launch?

Ropes, shackles, and chain can look surprisingly different after a few months of hiding away from sight. Yet, it’s a familiar story. The boat was safely stowed away and winterised, the warps and lines cleaned and bagged, ready for the new season. But somehow, when spring breaks and you take the lines out ready for action, the chafe and rust fairies appear to have sneaked in over the past 4 or 5 months.

In reality, things probably haven’t changed much from when you put them away. Over the course of the previous season, UV rays, abrasion, and corrosion were imperceptibly slowly working at your kit - day to day, not much changes. Then you return in the spring with a fresh eye and realise that closer inspection is required. After all, a spring forecast can quickly disturb the peace of mind when you first leave your boat moored, even on a quiet launch day.

So, a thorough inspection of the mooring system must be on the jobs list before your yacht can go back in the water. There are a few different mooring types to consider, each with a particular set of checks.

Inspection of Mooring Lines used alongside pontoons and onto harbour walls

Mooring alongside a pontoon is becoming increasingly popular as coastal marinas continue investing and expanding their capacity. Typically, this type of yacht mooring will rely on several mooring lines to secure the boat to the pontoon. Purpose-built pontoons usually feature rope-friendly cleats at a fixed height above the water.

Chafe, therefore, is usually minimal due to the load being spread around several warps and the relatively shallow angles from pontoon to deck level.

Warps need to be inspected:

- along the length of the line (especially if the warps don’t have set positions)

- inside the loop of any soft splice

- at the splice itself for any signs of deformation or chafe

- at the throat of any splice in contact with a thimble to ensure the eye or loop is still a tight fit

Although the Marina fees commonly cover maintenance of the pontoon itself. It’s worth inspecting all the cleats around your berth to ensure nothing is damaged or loose, especially if you find a chafe point in a line.

Regarding chafe and UV damage, most mooring warps are manufactured using polyester. Polyester has the best natural UV resistance of any fibre and is highly abrasion resistant. A good quality 3-strand or braided Polyester line, such as

LIROS 3 Strand Polyester or LIROS Braided Dockline 00133

should last several seasons. Signs that the line is wearing well include a smooth homogenous diameter with relatively few parted individual strands. Lines are expected to change from a slightly shiny to a matt finish. Any damage to the cover of a double braid line that exposes the core requires the line to be replaced.

Not all mooring points are very sympathetic to your lines or your hands. For example, long shorelines to a harbour wall or even mooring alongside a wall may require using bollards that are less than kind on your lines. It will be important to check for chafe, particularly around soft eye splices and any part of the line that comes into contact with the wall.

Inspection of Swinging Moorings and Trot or Pile Moorings

Swinging moorings utilise fewer warps than when mooring alongside. Typically, the full load of the yacht is taken by one primary bridle or strop with a backup laid in place, ready to take the load should a failure occur. Inspection criteria and maintenance schedules for everything from the buoy downwards must be in conjunction with the local authority and are not covered here.

Everything from the buoy up to the boat should be inspected:

- along the entire length of the line (especially where the strop passes through fairleads or over a bow roller)

- inside the loop of any soft splice

- at the splice itself for deformation or chafe

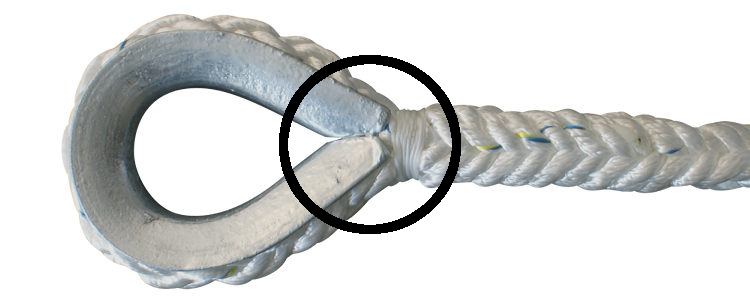

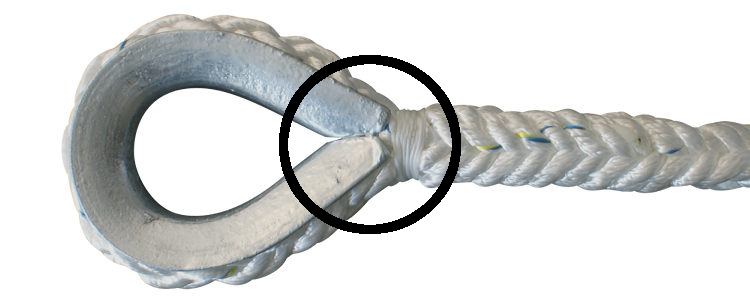

- at the throat of any splice in contact with a thimble to ensure the eye or loop is still a tight fit

- on the bearing edge of the thimble

- on the bearing edge of the shackle pin and the opposite bearing edge.

Pay special attention to the interaction between the thimble and the throat of the splice. Teardrop thimbles occasionally rotate in the splice or have unwanted burs and damage from use. This area is always worth meticulous scrutiny, and replacement of the warps should be a priority if any thimble rotation cannot be corrected and re-whipped - see picture above.

Nylon or Polyester for Mooring Warps

Mooring strops for swinging and trot moorings tend to be Nylon rather than polyester. Nylon fibre (polyamide) is commonly used because it is stronger and has more stretch than polyester. Nylon is ideal when strops are generally just a few metres and need to take all the load of holding the boat.

Even allowing for the extra strength and stretch of Nylon, single swinging mooring strops are usually several sizes bigger than the warps used for mooring alongside.

N.B. Always use Anchorplait Nylon rather than a 3-strand rope for single mooring warps because a 3-strand warp may cockle or unravel when continually twisted against the lay of the rope by the yacht swinging around the mooring.

Anchorplait Nylon is the rope that will not cockle.

UV damage is less of an issue due to the volume of material hidden from the sun’s damaging rays in the middle of the line. The increased size is also an extra wear-resistance safety factor. Threading anti-chafe tubular webbing onto the strop will afford additional protection against abrasion and UV deterioration. However, even with a larger diameter, the same rules apply as with the mooring warps for mooring alongside. Signs that the line is wearing well include a smooth homogenous diameter with relatively few parted individual strands. A healthy line may show signs of general wear but no specific areas of increased damage.

Dissimilar metals and thimbles in Mooring Systems

Where dissimilar metals have been used in contact with one another, look for corrosion on the contact point and accelerated corrosion in surrounding areas. If any more than 5-10% of the material has been removed, then it is advisable to replace the item.

For further advice on correctly specifying your mooring equipment, please visit our mooring category page with its wealth of product specification information.

Jimmy Green Mooring Category Page

Main Menu

Main Menu

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Main Menu

Back

Main Menu

Back

Back

Back

Back

Back

Back

Back

Back