A guide to choosing the right replacement running rigging lines

Purchasing replacement lines is often a straightforward process. Especially, if you're happy with the performance of the existing line and can identify what it is. The length can easily be specified by measuring an existing halyard or sheet and can even be guessed fairly accurately, from schematics if you are familiar with your deck layout. The nominal diameter is slightly trickier because different brands use different volumes of fibre to achieve their specifications creating slight variations in comparable ropes. If in doubt, deck hardware is often a good place to check for recommended line diameters.

The difficulty arises when considering an upgrade or you're not entirely sure what you already have on board. At this point, the material to be used, the construction and the diameter of the rope all need to be considered. These factors have a significant influence on the overall cost and performance of your line. This guide aims to help you choose the right line at the right price.

Rope Materials

There are many more fibres available for the truly discerning sailor, however, this article sets out the 5 most common ones found in our product range.

Listed in order from most expensive to most economical, they are Vectran, Dyneema, Technora, Polyester and Polypropylene.

- Vectran is the strongest and most expensive fibre and has very low elongation over time (creep). It is commonly impregnated with a UV stabiliser.

- Dyneema is very nearly equal to Vectran in terms of strength and stretch and is also usually impregnated with a UV protective coating.

The price advantage over Vectran makes this a popular choice with rope manufacturers at the upper end of the market.

- Technora has very high abrasion and UV resistance and is commonly blended into the cover/jacket of a braid on braid line.

- Polyester is the most common fibre with excellent UV resistance, good breaking strains and low stretch characteristics. It is available in a bright monofilament fibre and a softer, matt finish, spun yarn.

Bright polyester fibres are low stretch e.g. braid on braid bright white polyester. The softer feel, spun yarn has less strength and is slightly stretchier. Spun yarn is typically used for the cover/jacket on e.g. 16 plait matt polyester.

- Polypropylene is the lightest (doesn't absorb water) and cheapest fibre. However, it is stretchy and susceptible to UV.

Rope manufacturers have traditionally used different fibres for the core and the cover, in order to make the most of their relative advantages, but can now produce even better ropes by blending different fibres together, in either the core or the jacket.

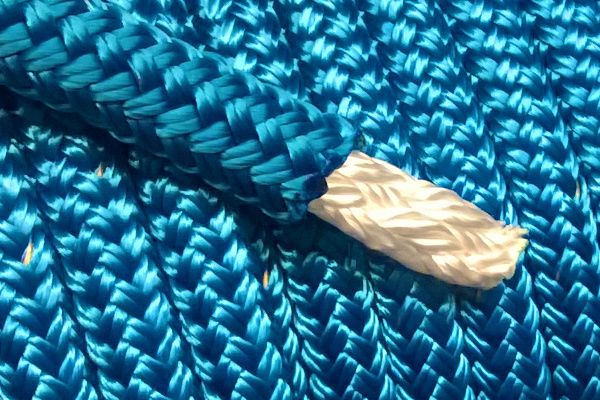

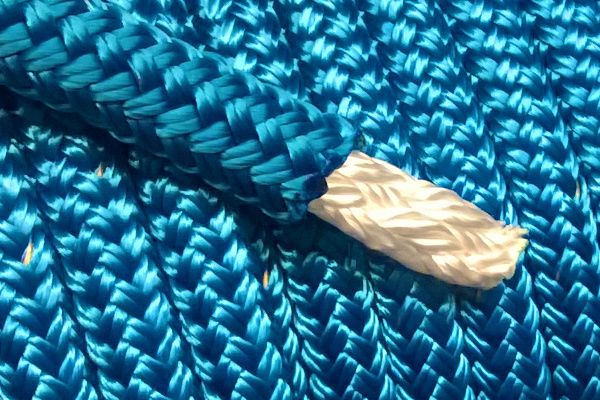

Rope Construction

The majority of lines are comprised of a braided core and a braided jacket. The most common cruising lines are 100% polyester (cost effective). The weight of fibre in these lines is usually balanced equally between the cover and the core and can be spliced using the double braid splice.

Marlowbraid is the exception as it has a 3-strand core which slightly reduces stretch for a very modest increase in price. The downside of this construction is that it tends to flatten around sheaves and winches.

N.B. braided lines with a polypropylene core may make a saving but will be reflected in a marked lack of performance particularly with regard to extra stretch where it is not desirable.

The construction of the cover also has a bearing on abrasion resistance. Generally, the covers with a tighter weave or 'more plaits' e.g. 8, 16, 24 or 32 plaits offer a sliding scale of improved wear resistance.

Stronger fibres such as Dyneema or Vectran are required to significantly increase the strength of a line and reduce its stretch. Typically, these fibres are used in the core which is therefore much stronger than the cover.

These lines then have to be spliced using the core dependent method which in turn means the weight of fibre in the cover can be reduced.

Cost vs Performance

The cost is directly related to the amount of Dyneema/Vectran content in the finished rope and therefore related to the strength and stretch.

It, therefore, follows that the strongest (and most expensive) line for a given diameter does not have a cover and is 100% 'core'. However, Halyards and sheets still rely on the cover for grip and abrasion resistance in clutches and on winches. The solution is to strip the cover from the core shortly after the winch or clutch. This can only be done with core dependent ropes.

All the fibres mentioned can be blended to produce covers with different properties. Racers may use a polypropylene/Dyneema blend for lightweight sheets or a technora/polyester blend for sheets that get through a lot of work. Cruisers are less likely to have sailing condition specific requirements, so a standard polyester cover heavy enough to give good longevity is usually the best bet.

Choose the right line

The full range of lines supplied by Jimmy Green Marine can cater for both the cruisers and the racers. So we have arranged the lines on a sliding scale to help you decide where to aim. Specifications are based on 12mm lines.

Whether you're a cruiser looking to strengthen up your lines for a more adventurous outing or a racer looking for a better price point Jimmy Green has a line for you.

Sheets and Halyard Selection Chart

| Line |

Strength |

Stretch |

Cover Fibre |

Cover construction |

Core Fibre |

Core construction |

| LIROS Matt Plait |

2400kg |

5% |

Spun Polyester |

16-plait |

Polyester |

Braided |

| LIROS Braid on Braid |

3200kg |

5% |

Polyester |

20-plait |

Polyester |

Braided |

| LIROS Herkules |

3500kg |

5% |

Polyester |

1:1 |

Polyester |

Braided |

| Marlowbraid |

4450kg |

4% |

Polyester |

16-plait 1:1 |

Polyester |

3-strand |

| LIROS Cruising Dyneema |

4800kg |

2% |

Polyester |

high twist 32-plait |

SK78/polyester |

Braided with cover |

| Marlow D2 Club |

5200kg |

2.5-3% |

Polyester |

16-plait 1:1 |

SK38 |

Braided |

| Marlow D2 Racing |

6690kg |

1.5% |

Polyester |

24-plait |

SK78 |

12-strand |

| LIROS Racer |

7200kg |

1.5% |

Polyester |

high twist 32-plait |

SK78/polyester |

Braided with cover |

| Marlow GP78 |

6690kg |

1.5% |

Polyester/Technora |

24-plait |

SK78 |

12-strand |

| LIROS Control XTR |

112000kg |

< 1% |

Polyester/Technora |

high twist 32-plait |

SK99 |

12-strand |

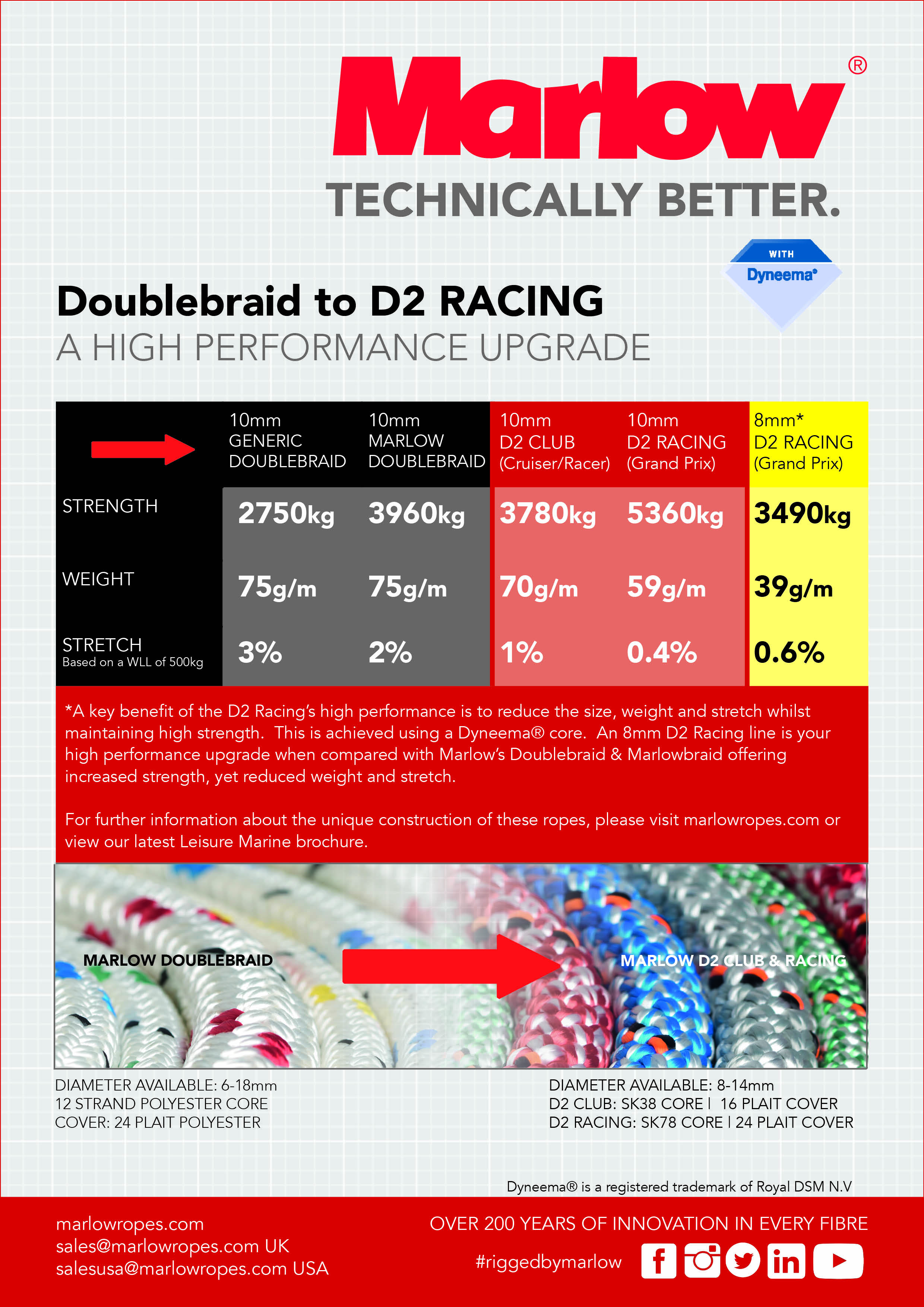

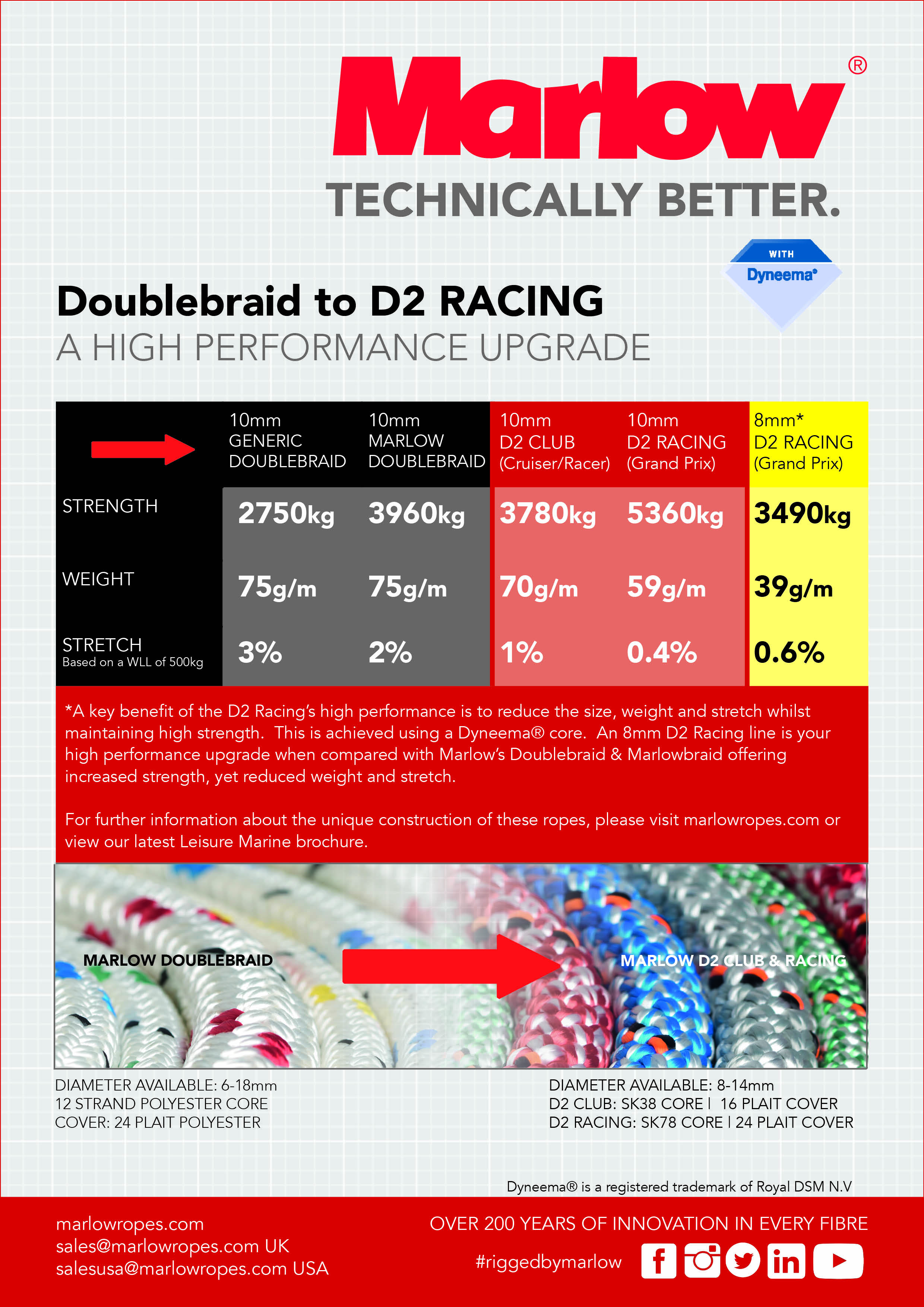

You can also find further information on the infographic below. The stretch percentages are based on a 500kg working load rather than an ultimate breaking load. This accounts for the difference between the infographic and the table above.

Shop for Sheets and Halyards

Main Menu

Main Menu

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Main Menu

Back

Main Menu

Back

Back

Back

Back

Back

Back

Back

Back