5mm Stainless Steel Guardwires

Click on the boxes below to reveal your custom build options - Highlight your choice from the drop down menus

HOW TO MEASURE ILLUSTRATIONS PLUS DETAILED CUSTOM BUILD INSTRUCTIONS

More Information

Features

5mm Stainless Steel Guard Wires produced to your specification using KOS, the world's best wire, 316 bright polished stainless steel, plain or PVC coated together with terminals from premium world recognised brands.

Finished to your exact measurements and bespoke requirements and professionally terminated with meticulous care by the Jimmy Green Rigging Team

N.B. It will be assumed any adjustable end-fitting will be set at the 2/3 open position.

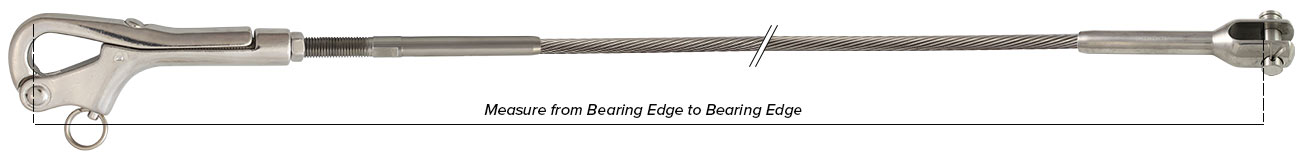

All measurements are taken from bearing edge to bearing edge, see below.

Please allow a proportional gap of approximately 200mm-300mm (8''-10") if using lanyards at one end

N.B. Pictures of end-fittings are not to scale - They are illustrative only

Custom build 5mm 1x19 stainless steel guard wires are cut, roller swaged and talurit pressed on site by the Jimmy Green Rigging Team, using only top quality materials from premium, industry recognised brands and manufacturers.

5mm 1x19 stainless steel wire features:

Exclusively sourced from KOS, the world's best wire manufacturer

Manufactured using 316 marine grade stainless steel to 1.4401.

Available coated to 8mm diameter in white PVC

Manufacturer Minimum Break Load 2000kg

5mm 1x19 talurit terminations:

Sta-Lok British standard copper ferrules

Sta-Lok and Hamma thimbles

Terminated on a 20 tonne Cabco Talurit hydraulic press

5mm 1x19 swage terminations:

All 316 stainless steel

Premium Brands e.g. Sta-Lok, Navtec, OS/BSI, Bluewave, Hamma and Petersen

All wire terminals are roller swaged onto the wire using Wiretechnik Roller Swaging Technology

Roller Swaged using a 3 phase electrically powered, state of the art, hydraulic Wireteknik Roller Swager

Bearing Edge to Bearing Edge Measurement:

The picture shows examples for the Bearing Edge - The point from which your measurements will be taken.

Measurements on Swaged Studs will be from the extreme end of the terminal:

Stud terminals for 5mm wire generally require a 9.5mm absolute minimum clearance diameter hole in the stanchions for them to pass through without getting stuck or meeting awkward resistance:

DETAILED DIMENSIONS FOR GUARDWIRE SWAGE STUD TERMINALS

The Jimmy Green Rigging Team aim to produce your rigging within a tolerance of + or - the diameter of the wire.

Glossary

RS = Rigging Screw

1/4 or similar refers to UNF thread size

M6 or similar refers to Metric thread size

RH = right-hand

LH = left-hand

Quality Control

The Jimmy Green Rigging Team undertake to check your wire and terminals meticulously during the production process to ensure that they are 100% First Quality.

The Jimmy Green Despatch Team make a second thorough quality inspection of each item, including a careful check that it matches your order, before packing it into your parcel

Please take extra care when ordering because once a bespoke item has been started (cut) it can neither be cancelled nor returned for a refund.

- Purchase Type - Custom Build