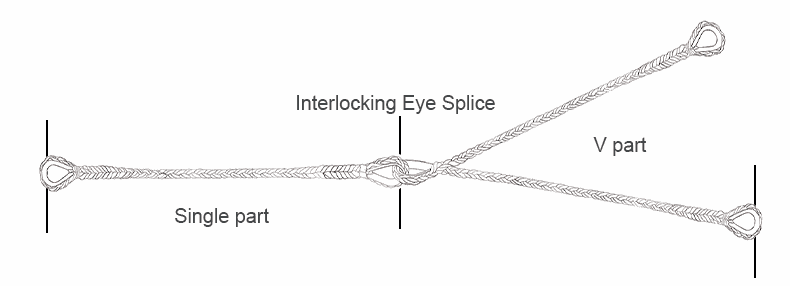

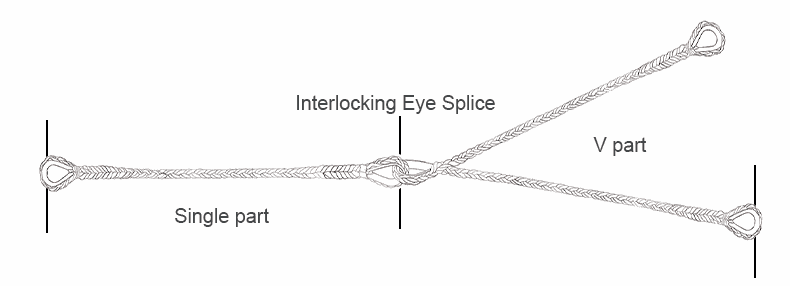

Custom Build a Jimmy Green Y shape bridle in two separate products - the single part and the V part - see below for the two component products for each rope diameter.

Custom Build a bridle to divide the load between two cleats - spliced and whipped to your bespoke requirements by the Jimmy Green Rigging Team.

Build the Y shape bridle in two components and add each to your cart as you go: Build 1 - Single part ~ Build 2 - V part.

The Rigging Team will join the two parts together by interlocking the thimbles in the connecting splices.

Jimmy Green Y Shaped Anchorplait® Bridles:

- A Jimmy Green Y-shaped bridle is based on the Anchorplait centre eye splice (with or without a thimble/chain hook).

- A Y-shaped bridle consists of two interlocking parts:

- The single part from the outboard (anchor/mooring) end to the interlocking arrangement that creates the Y shape

- The interlocked V part that completes the Y shape

- The V part consists of

- a continuous line centred around a hard thimble eye with a Brummel locking tuck splice.

- two separate lines, with the hard thimble eye splices interlocked onto the hard eye splice of the single part

- two separate lines, with the hard thimble eye splices connected to the single part with a Colligo Bridle Plate

- The strength of the bridle is therefore not reliant on a Y Joining Splice, i.e. splicing two separate ropes together

- The maximum deployment angle must always be set up with caution, but the centre eye splice is much less prone to failure at a wider than optimum angle than any joining splice between two separate ropes.

- It is not possible to successfully put a centre eye splice in a rope of three strand construction

Y Bridle Custom Build Instructions

Available in: Octoplait, White LIROS article 01058 Anchorplait, White with distinctive easy splice markers LIROS article 01058JG Octoplait Polyester, Black or Navy LIROS article 01049

Suitable for: Anchor chain snubbing, permanent mooring warp applications and for use with towing lines, para-anchor rodes or yacht drogue warps

Size guidelines vary for application:

General Guide for Determining the Size of your Anchor Rode

LIROS Anchorplait® White Nylon Article 01058JG - 100% Nylon (Polyamide) - Facts, Features and Plus Factors

Anchorplait® is a Jimmy Green Marine UK Registered Trademark.

Anchorplait® is manufactured exclusively by LIROS Ropes for Jimmy Green Marine.

Anchorplait® features Easy Splice Markers designed by the Jimmy Green Rigging Team.

The eight-strand construction (two pairs left hand, two pairs right hand) delivers a balanced performance with no twist under tension.

In fact, Anchorplait falls and flakes like a chain.

Anchorplait is the rope that will not cockle - the interlocking opposing pairs resist rotation.

Anchorplait is the optimum rope for creating the V part of a Y Bridle because the centre eye splice is more secure than any joining splice.

LIROS Anchorplait Nylon Facts, Features and Plus Factors:

- LIROS manufacturing excellence and consistency

- 100% Nylon (Polyamide)

- UV stabilised

- Square braid construction

- Non-kinking

- Balanced braiding

- The eight-strand construction (two pairs left hand, two pairs right hand) ensures a balanced performance with no twist under tension

- Zero possibility of cockling - the interlocking opposing pairs resist rotation

- Dependable, robust strength

- Reliable durability

- Excellent weathering and wear resistance

- Remains flexible for the duration of its working life

- Supreme Shock Absorbing Elongation, >20% working load stretch

- Spliceable into a robust, secure V-shape termination – centre eye splice

LIROS Anchorplait and Octoplait Nylon Break Load in daN:

10mm 2400daN - 12mm 3300daN - 14mm 4400daN - 16mm 5600daN - 18mm 7000daN - 20mm 8140 daN - 24mm 11800daN

LIROS specify their minimum break loads in Dekanewtons (DaN)

Kg force is a more recognisable illustration of strength, so you can convert the LIROS DaN values as follows:

1 Dekanewton = approximately 1.02 kg force

Therefore, the strength for any given diameter will be higher in kg than in daN e.g. 11800daN = approximately 12036kg

Plain white LIROS Octoplait Nylon article 01058 with only LIROS tracer yarns is also available.

LIROS Octoplait Polyester Article 01047 and 01049:

The eight-strand construction (two pairs left hand, two pairs right hand) delivers a balanced performance with no twist under tension.

In fact, Octoplait falls and flakes like a chain.

Octoplait will not cockle because the interlocking opposing pairs resist rotation.

LIROS Octoplait Polyester Facts, Features and Plus Factors

- LIROS manufacturing excellence and consistency

- 100% Polyester

- Excellent shock absorption

- Superlative weathering and UV resistance

- Excellent wear resistance

- The 8-strand construction (two pairs left hand, two pairs right hand) ensures a balanced performance with no twist under tension

- Zero possibility of cockling - the interlocking opposing pairs resist rotation

- Falls and flakes like a chain

- Remains flexible and supple for the duration of its working life

- Super pliable

- Reliable load capacity and abrasion resilience

- Excellent ductile shock absorption >15% working load stretch

LIROS Break Load: 10mm 2000daN ~ 12mm 2400daN ~ 14mm 3800daN ~ 16mm 4700daN ~ 18mm 5800daN ~ 20mm 7600daN ~ 24mm 11600daN

LIROS specify their minimum break loads in Dekanewtons (DaN)

Kg force is a more recognisable illustration of strength, so you can convert the LIROS DaN values as follows:

1 Dekanewton = approximately 1.02 kg force

e.g. 11600daN = approximately 11832kg

Jimmy Green Y Bridle Online Custom Build Instructions

The Jimmy Green Rigging Sales Team are happy to help you to build and order a bridle to meet your bespoke requirements.

Follow these steps to get an instant quote and complete the order yourself

Build a Y shape in two components and add each one to your cart as you go:

Build 1 - Single Part

Follow these steps, building a single line from the outboard end:

Select Option 1 - Make your choice of finish on the mooring/anchoring end

Select Option 2 - Pick your rope and enter the length of the single part. This will be the length from the bearing edge to the bearing edge of the thimbles

Select Option 3 - Add an anti-chafe option, if required

Select Option 4 - Add a compensator option, if needed

Select Option 5 - Select the interlocking thimble eye splice

Build 2 - V Part

Follow these steps, building a > from the top:

Select Option 1 - Make your choice of finish to attach to your cleats onboard

Select Option 2 - Pick your rope and enter the length of the first tail. This will be the length from the bearing edge to the bearing edge.

Select Option 3 - Add an anti-chafe option, if required

Select Option 4 - Add a compensator option, if required

Select Option 5 - Make your choice for interlocking the single part to the V part

Select Option 6 - Pick the matching rope and enter the length of the second tail. This will be the length from the earing edge to the bearing edge.

Select Option 7 - Add a compensator option, if required

Select Option 8 - Add an anti-chafe option, if required

Select Option 9 - Make your choice of finish to attach to your cleats onboard

N.B. Ensure that you select matching rope for each tail and a matching finish for attaching to your cleats to create a symmetrical V

The mooring compensators will be fitted closer to the centre eye splice unless otherwise specified by email. Any anti-chafe can be suitably positioned to protect the tails as they pass through the fairleads and onto the cleats.

If, for any reason, you would prefer an asymmetrical configuration with non-matching splicing/whipping on the two tails and one tail longer than the other, please order as above and send an email confirming your desired specification with a sketch if possible, e.g. If your fairleads are not positioned the same, port and starboard, you may prefer a loop splice on the end of one tail for a fixed length and a longer second tail with a whipping to adjust the bridle to take the load equally.

Once you have made a selection in all the drop-down boxes available, the website will generate the following:

- a picture version of what you have chosen

- an overall length

- a price including VAT and any current applicable discount

N.B. The website will accept a length to 3 decimal points. However, this is not practicable for mooring and anchoring bridles.

For short strops and bridles, the Jimmy Green Rigging Team aim for a bearing edge to bearing edge measurement accurate to within + or - the diameter of the rope. However, all ropes stretch to some extent under load. Mooring and Anchoring ropes stretch more than most. Therefore, this degree of accuracy can't be guaranteed. Please allow for stretch under load when determining your finished length.

Next:

Check the item is designed as you wish. You can alter any box, and the website will update the picture and the price.

Select Continue Shopping or Proceed to Checkout

To view a summary of the items you have selected, hover over the pale green Basket icon in the green banner top right of the webpage.

To view a detailed description of the items you have selected, click on the pale green Basket icon in the green banner top right of the webpage or hover over Basket and click on Checkout.

Jimmy Green Measurement Advisory

The finished length is measured from the bearing edge to the bearing edge = the inside face of a loop/thimble where, e.g. a shackle pin would take the load and, therefore, NOT the overall outside length.

The splicing price includes the extra rope required to make the splice and meet the overall finished length.

Quality Control

The Jimmy Green Rigging Team undertake to check your rope meticulously during the production process to ensure that it is 100% First Quality.

The Jimmy Green Despatch Team make a second thorough quality inspection of each item, including a careful check that it matches your order, before packing it into your parcel.

Please take extra care when ordering because once a bespoke item has been started (cut), it can neither be cancelled nor returned for a refund. RETURNS

Y Shape Bridles for Multihulls:

Due to the broader beam, the angle of the lines to a central point from each hull will need to be wider; otherwise, the meeting point will end up too far forward of the bow, resulting in too big a swinging arc and a subsequent loss of control.

It is therefore advisable to consider separate hardware-connected lines to cope with the increased directional loads created at the meeting point:

- Two separate lines to create a V shape bridle connection

- Three separate lines to create a Y shape bridle connection

For a three-way connection, it is possible to interconnect the two stainless steel thimble eye splices of the V part into the stainless thimble of the single part, but only if the single part is of an increased diameter - this is a bespoke solution which will need to be checked for each combination.

Mantus Marine manufacture a Bridle Plate solution.

Single lines can be three strand (twisted lay) construction: 3 Strand Strops rather than Anchorplait if preferred.

Main Menu

Main Menu

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Main Menu

Back

Main Menu

Back

Back

Back

Back

Back

Back

Back

Back