Profurl design and manufacture a comprehensive range of Manual Reefing Systems for Flat Heasails i.e. Jibs, Genoas and Yankees for cruising and racing.

The Jimmy Green Rigging Sales Team are available to help you select the correct system for your individual yacht and your anticipated sailing requirements.

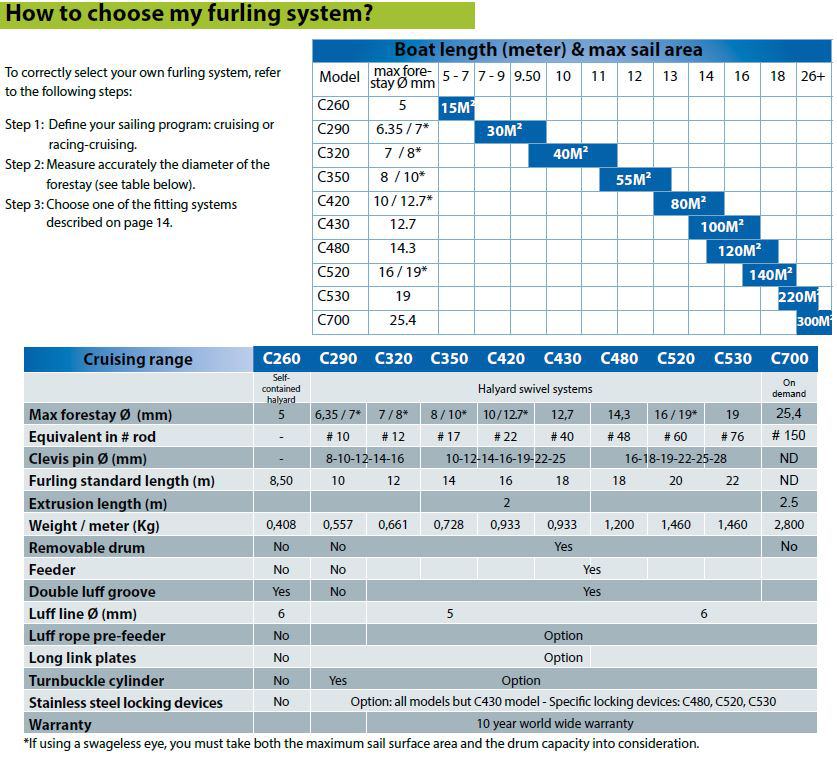

Cruising models are available for yachts between 5 and 26 metres. They feature a round profile, silver, anodised, double luff groove foil. Racing models are offered for yachts between 6 and 20 metres. They feature an aero shaped, black, anodised, double luff groove foil.

PROFURL have decades of experience in producing Headsail Reefing Systems for Cruising and Racing Yachts. The first furling system was launched in 1980 and Profurl quickly became a technological pioneer as well as the worldwide market leader in the field of Furling Gear.

PROFURL has been part of Wichard, the world famous French marine hardware manufacturer since 2002 – Profurl is manufactured under the Wichard umbrella in France guaranteeing quality and peace of mind

Research and Development is an important factor in the continuing quality and reliability of Profurl Reefing.

All Profurl products are designed and tested by the Profurl team of highly skilled engineers, assisted by the latest computer tools and software, based in Pornichet on the west coast of France.

PROFURL products are submitted to a range of scientific tests in order to test their resistance, beyond what could actually be experienced on a yacht. They are then developed and honed to perfection with the help of feedback from the world’s most respected riggers, sail makers and sailors

The Profurl Manufacturing Process is meticulous

- The raw materials are carefully selected

- The specifications are finalised with a view to extensive and rigorous use

- The mechanical parts are machined using a controlled patented process

- The extrusions are produced from alloy of the purest metallurgical quality

- There are no castings because they can contain impurities which can cause inherent weaknesses

- Each part is micro-balled for a perfect surface finish and anodised in a special green-gold process to afford the best protection against the harshest marine environment

Profurl Plus Factors

- Comprehensive range to meet the needs of all yachts

- Profurl Manufacturer Extended 10 year World Wide Warranty on manual furling systems

- Available with:

- Standard short link plates

- Long plates

- Lose to the deck fitting

- Turnbuckle cylinder

- Below deck

- Reliable Performance

- No maintenance required.

- Two possible forestay diameters for each furling system (in most cases)

- Retro-fittable on an existing forestay (in most cases)

- Light and robust anodised foil extrusions

- Maintenance free ball bearings

- Insulation of dissimilar metals

- Completely traceable and accountable Quality Control process through engraved serial numbers

- Professional Profurl back up

- Global network of distributors.

- 40 years of manufacturing experience

- Made in France

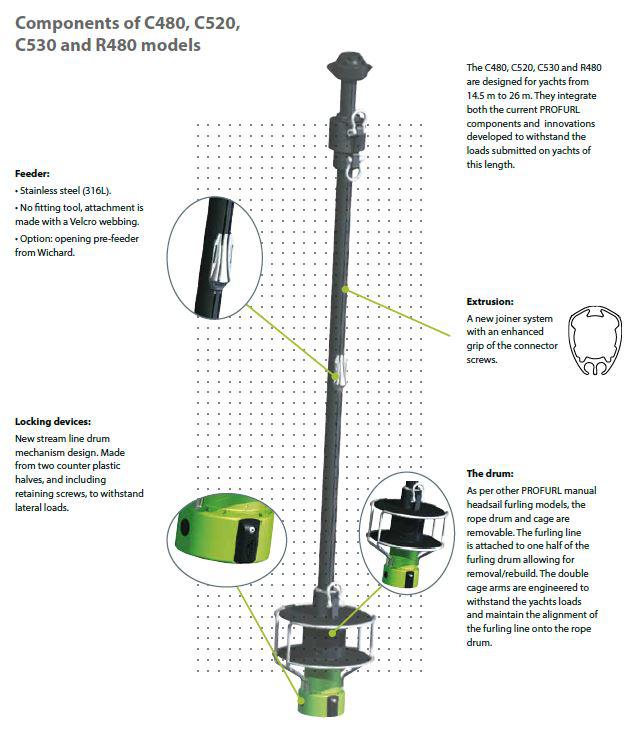

The Profurl Manual Reefing Cruising Range boasts 9 different models dedicated to yachts from 5 metres up to 26 metres length overall featuring:

- Silver anodised extrusions

- Integrated, innovative design elements e.g. double cage arms and an extremely efficient feeder design.

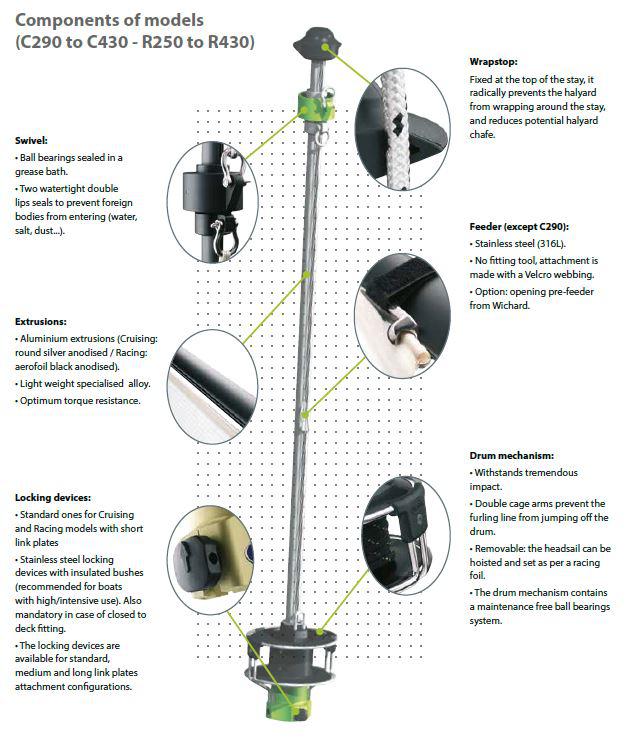

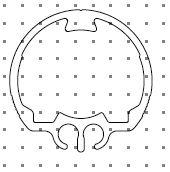

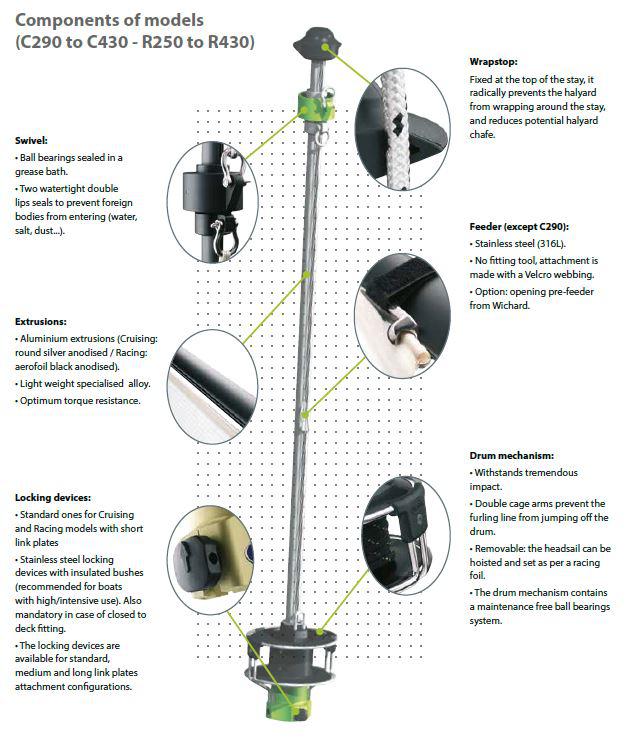

Cruising Foil Profile ~ Double Cage

Safety Factors

Double cage arms (exclusive to PROFURL) prevent the furling line from jumping off the drum and allow the furling line to re-align onto the drum by simply pulling on the line

Special stainless steel locking devices are fundamental to the successful performance of the close to deck fitting system

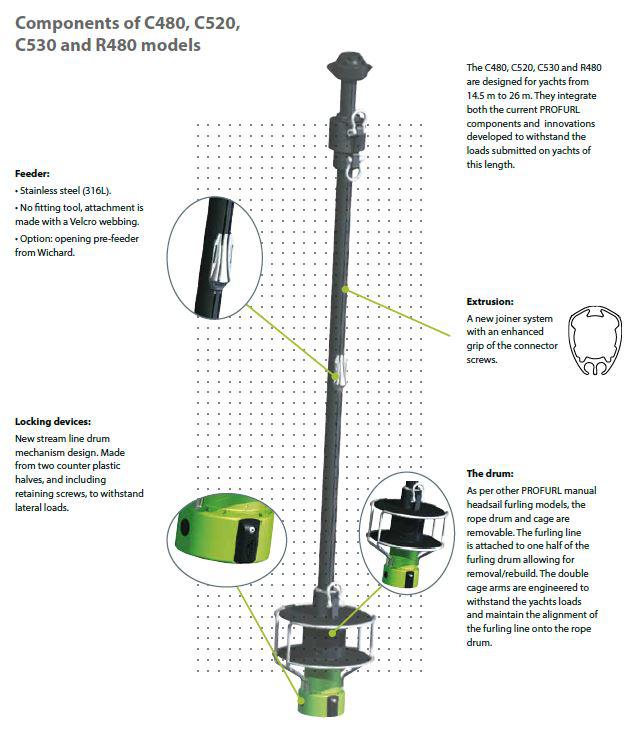

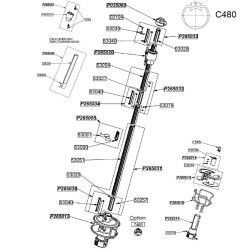

On the C480, C520, C530 and R480 models, special locking devices have been designed to withstand the higher loads

Meticulous Raw Material Selection process

- Each component is submitted to bench-tests in order to assess their resistance

- Ball bearings are made of high strength 100 C6 carbon steel

- Drums are made of high impact plastic

- Extrusions use a special alloy (6106) and offer the optimum weight : resistance ratio

- The feeder and the opening pre-feeder are made of stainless steel (316L), except for C290

Performance Aspects

- Special Alloy (6106) Extrusions dictate that the foils are lighter and stronger

- The ball bearings have an optimised weight : resistance ratio.

- Wichard sail pre-feeder is standard issue included in the box for racing models facilitating a faster sail hoist.

Reliable, Maintenance Free System

- High strength 100 C6 carbon steel ball bearings - sealed in a grease bath for optimum working load and corrosion prevention.

- Watertight double lip seals (two) prevent any foreign body ingress into the bearing mechanism e.g. salt, sand, dust, seawater.

- Non deformable plastic drum for maximum impact resistance.

- UV Stabilised for long life in the sun

PROFURL manual furling systems have been designed for hassle free manoevres

Single handed hoisting is easy to achieve with the standard feeder The optional opening pre-feeder (standard issue on Racing Models) manufactured by Wichard makes the introduction and progress of the luff rope/tape up through the luff groove even more smooth and snag free.

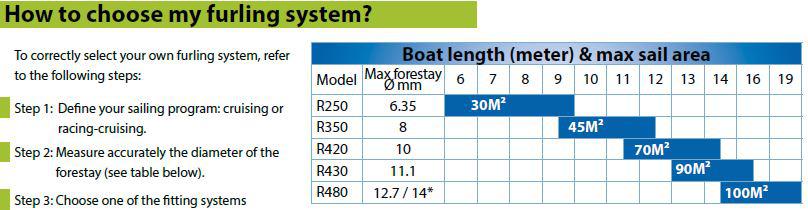

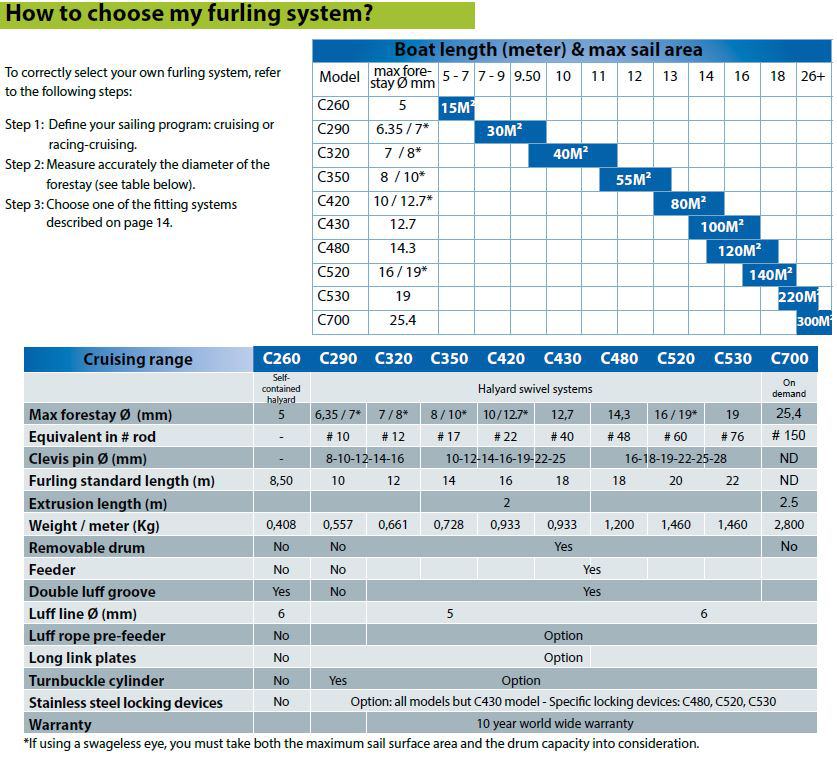

Determine the correct Cruising Manual Furling System for your yacht using the table below

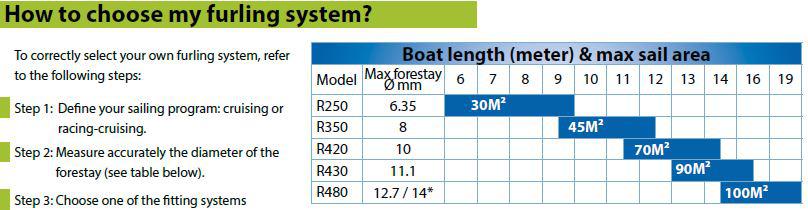

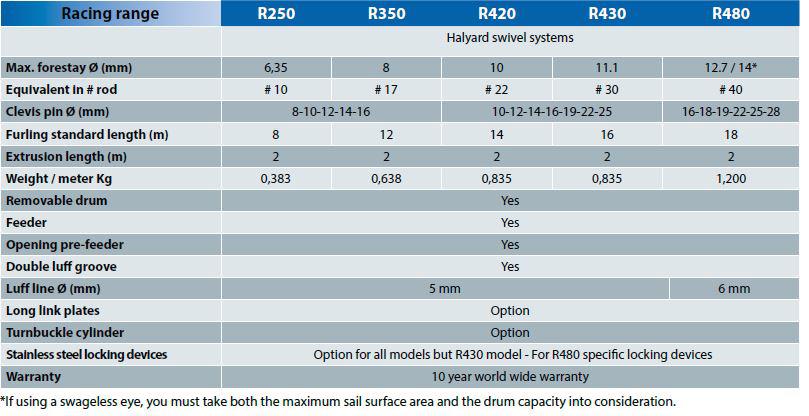

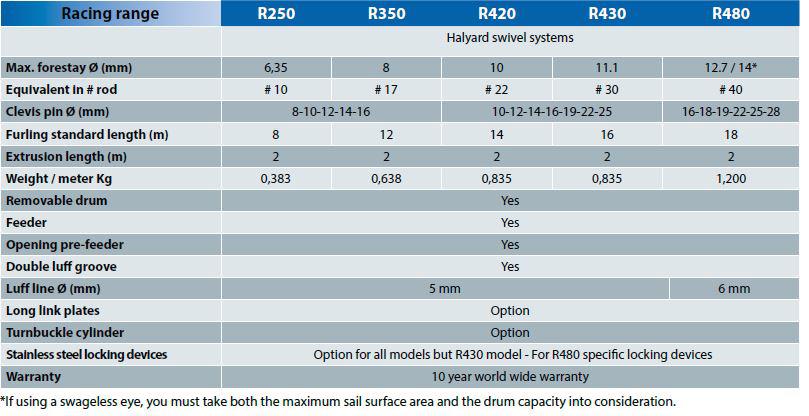

The Profurl Racing Manual Reefing Range features:

- 5 models for boats from 6 to 20 metres length overall

- 10 year world wide limited manufacturer warranty

- Multiple Fitting Options - adjustment plates, long link plates, turnbuckle cylinder, below deck fitting, stainless steel locking devices

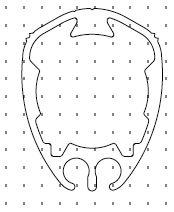

- Streamlined aerodynamic black anodised foil section

Determine the correct Racing Manual Furling System for your yacht using the table below

Determine the correct Racing Manual Furling System for your yacht using the table below

Profurl have designed a Manual Reefing System dedicated to boats from 5 up to 7 metres length overall

The Profurl C260 model is a self-contained halyard furling system

Profurl C260 Plus Factors

- Cost-effective

- Easy to install on the existing forestay

- Maintenance Free

- Designed particularly with achieving a tight forestay on fractional rigs in mind

- Self-contained halyard helps to minimise forestay sag by reducing mast compression created by a combination of loads from the halyard and sail

- Simple installation - does not require a specialised attachment to the forestay stem head because it is simply attached to the lower swage terminal of the forestay (eye and holes, plates or turnbuckle)

- Ideal for Trailer Sailers - the C260 can be separated in two sections reducing the risk of damage while in transit

- Easy to operate - the self-contained halyard passes over a sheave box fitted into the top of the extrusion and returns down to a sheave and cam cleat. Once the sail is hoisted and tensioned, the remaining length of the halyard is used as a furling line

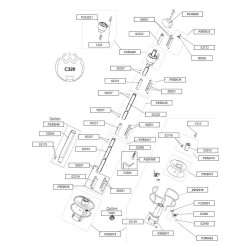

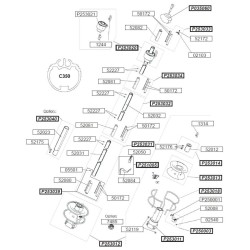

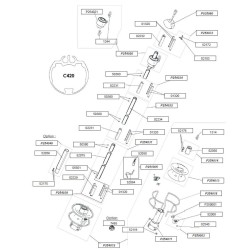

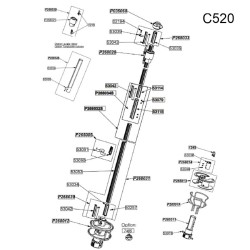

Profurl Installation Manual - C260 Profurl Installation Manual - C290 C430 R250 R430 Profurl Installation Manual - C480, C520, C530 R480

Main Menu

Main Menu

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Main Menu

Back

Main Menu

Back

Back

Back

Back

Back

Back

Back

Back

Determine the correct Racing Manual Furling System for your yacht using the table below

Determine the correct Racing Manual Furling System for your yacht using the table below