Replacing your Standing Rigging with Jimmy Green Marine

The task of replacing the standing rigging on a sailing yacht may seem daunting but there is a procedure to follow that can make it a relatively straight forward process for anyone who is reasonably practical.

The first decision is whether to tackle the job with the mast up or down.

If you have enough time together with the availability of a mast lift, then mast down is by far the easier option. The whole project will be much easier with the mast horizontal and chocked up on firm ground and accessible to work. You may even elect to carry out the upper mast inspection after lowering the mast to save going aloft in a bosuns chair. You will be able to purchase each wire with swaged terminals at both ends finished and ready to fit. You can order yourself online or with help from the Jimmy Green Rigging Team.

You can take confidence from the fact there is a good deal of adjustment on the rigging screws to allow for any minor errors in measurement. It’s worth noting that Team Jimmy Green set the turnbuckles at 2/3 open unless otherwise requested and undertake to produce the finished wires accurately to within plus or minus the diameter of the wire.

If the mast has to remain stepped, you need a slightly different approach, generally involving the purchase of each wire over long with the top terminal swaged. The bottom end will need to be finished in situ by cutting to the exact length and fitting a DIY swageless (mechanical) terminal. Modern Swageless terminals from Sta-Lok or Petersen are fairly simple to fit so you can be confident of success.

Rigging Checklist

- Rig Tune and Tension check on existing rigging

- Consider any design or specification alterations

- Close inspection of all components including measuring diameters

- Take photos

- Mark all tension settings (with tape above and/or below the rigging screw)

- Determine any possible improvements

- Order process for mast unstepped

- Order process for mast remaining stepped

Each step is explained more fully below:

1. Rig Tune and Tension check on existing rigging

Begin by checking that your current rigging is set up and tuned correctly. This need not be as technical as it sounds - you just need to be sure that you are copying a rig that works well. The essentials are mast rake and bend, athwartship vertical alignment and correct tensioning. You may want to elicit some professional advice but if your current set up performs satisfactorily upwind and downwind on both tacks/gybes, it may be best not to interfere with the current settings. The aim of the game is to replicate the old rig with a new one within parameters that allow for adjustment and tuning.

Look for extra unnecessary shackles or toggles which may have been added to compensate for the wire being too short and determine whether they can be omitted from the new rig.

2. Consider any design or specification alterations

The next step is to survey all aspects of the rigging including an assessment of whether the existing is the right design and specification for your anticipated purposes e.g Coastal, Offshore or Ocean Cruising, occasional or hard core racing.

3. Close inspection of all components

Carry out a thorough inspection of the rigging including all the wire, terminals and clevis pins. Establish the size of every component and make notes. A good quality pair of callipers is an invaluable investment for producing accurate results.

Once you have confirmed the wire diameter, the approximate length and identified the terminals top and bottom, it is a simple online exercise to get an accurate estimate of the replacement cost on JimmyGreen.com/standing rigging. Alternatively, Team Jimmy Green can readily produce a costing based on the same information.

4. Take photos

Take photos of everything including zoomed in detail of anything you are not sure about and any others that will serve as a reminder when fitting the new shrouds and stays.

Check for any signs of wear or structural damage and identify the probable cause. Problems can occur for many reasons e.g. misalignment leading to stress at an odd angle, fittings that allow unnecessary movement, lack of articulation due to missing toggles, undersize clevis pins or oversize clevis pin holes. Some of these may be part of the reason that you are replacing the rig so it is best to avoid repeating the issue on the new set up.

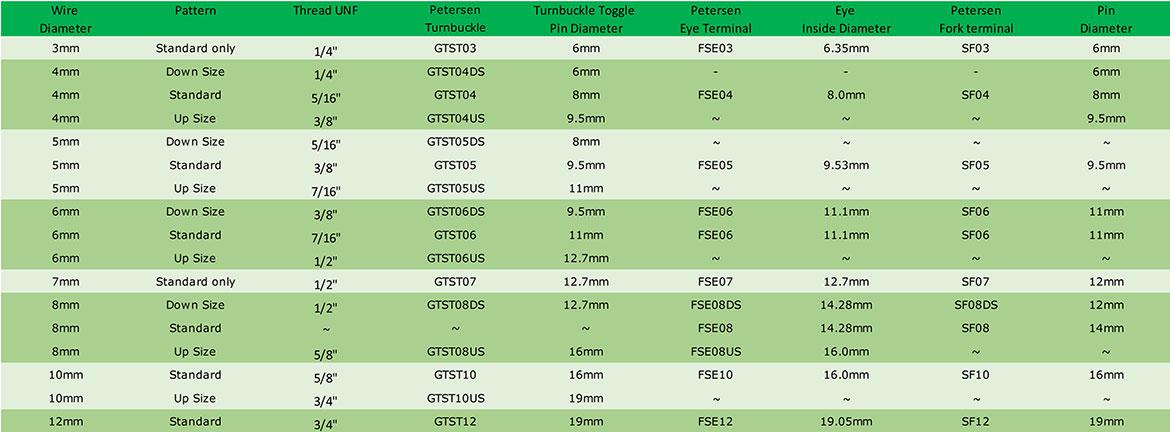

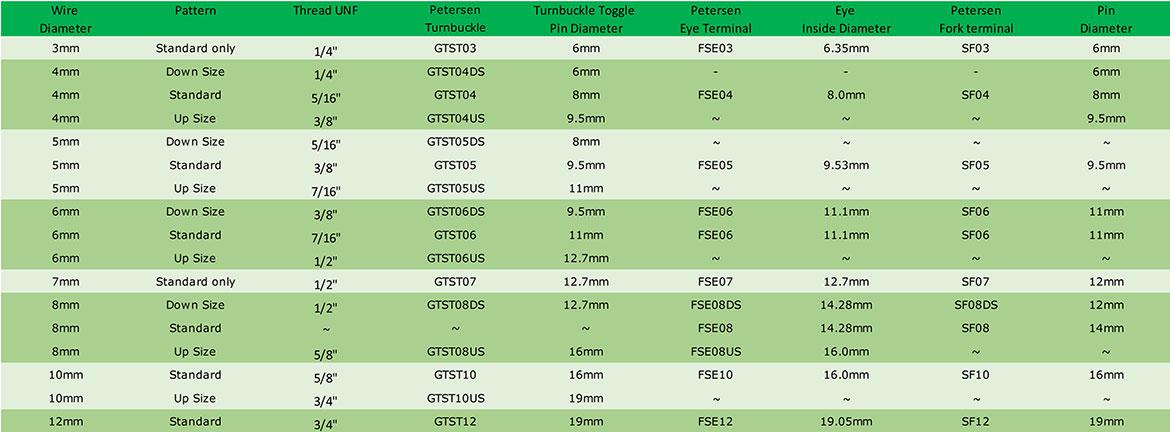

There are standard pin and hole diameters that correspond with the thread size of the studs in the turnbuckles. There is a varied choice of stud/turnbuckle sizes on each wire diameter. Components either side of the normal sizing ared enotes as Down Size and Up Size by Petersen Stainless Rigging. Threads are generally UNF or possibly the Metric equivalent. The table below sets out all the relevant sizes for standard, down size and up size components. If your rigging has special non standard characteristics, the Jimmy Green Rigging Team can source bespoke replacements or suggest suitable alternatives.

This chart is a guide only. Please check all dimensions before ordering your rigging.

5. Mark all tension settings

Make a note of all the turnbuckle settings before you disconnect any shrouds or stays by marking them with tape or taking photos. You will need to loosen all the turnbuckles to disconnect them at deck level.

Remember to return them to their noted settings before measuring. The new rigging can then be made to the required length with the optimum adjustment, normally 2/3 open.

6. Determine any possible improvements

One last check to ensure that there isn’t a change of fitting or a tweak in the set up that will make the new rig an improvement on the old one.

7. Order Process for Mast Unstepped.

Dependent on the time factor there are two main options to consider:

Option 1.

Determine the terminals required, measure the wires, make any adjustments and place your order either online or by emailing your requirements for Team Jimmy Green to load the order for you.

N.B. The old wires should be removed from the mast, pulled out taut with a little tension if possible to ensure that they are straight in readiness for measuring.

Measurements are from bearing edge to bearing edge of the pins or eyes.

For T terminals and studs, refer to our Standing Rigging Custom Build Instructions.

Label the individual stays. You may need them as an aide memoire when you come to fit the new standing rigging.

Check and double check your measurements and terminal fittings before ordering. Remember the old adage: “Measure twice, cut once”.

Option 2.

Remove the old stays, labelling them carefully as you go and noting any amendments required to length or fittings.

Coil the wires as neatly as possible.

Send them or bring them to Jimmy Green Marine for assessment and a quote.

This option puts the onus on the Jimmy Green Rigging Team to replicate your rigging accurately.

8. Order Process for mast remaining stepped

Establish the length of the existing shrouds and stays.

Measurements are from bearing edge to bearing edge of the pins or eyes.

For T terminals and studs, refer to our Standing Rigging Custom Build Instructions.

Order new wires with the required top terminals swaged on and the wire length appropriately over length for cutting and fitting in situ.

Order DIY swageless terminals for the bottom end.

The wire should be long enough so that it can be cut and fitted with the new swageless terminal to finish at the desired length.

N.B. Replacing the forestay will be tricky if it is fitted with a headsail furler and you may need professional help.

Standing Rigging Assistance Shop for Standing Rigging

Main Menu

Main Menu

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Back

Back

Main Menu

Back

Main Menu

Main Menu

Back

Main Menu

Back

Back

Back

Back

Back

Back

Back

Back