Running Rigging Rope Fibres and Construction Explained

Jimmy Green Marine offer a comprehensive range of braided lines suitable for use as a halyard, sheet or control line, but which one will suit you best?

Before you can order the diameter and the length, you need to narrow down the options based on Rope Fibre, i.e. what it is made of, and Rope Construction, i.e. how it is made.

These two factors significantly influence the overall cost and performance of your line.

This guide aims to help you make an informed decision based on the performance you want within your budget for the application.

Rope Fibres

These are the five most common rope fibres which will cover most applications whether you are cruising or racing:

This list is in order of cost: most economical to the most expensive - Polypropylene, Polyester, Technora, Vectran, Dyneema

- Polypropylene is very light, doesn't absorb water, floats as a consequence and is the cheapest fibre. However, it is stretchy and susceptible to UV.

- Polyester is the most prevalent fibre because it has excellent UV resistance, more than adequate breaking strain, and relatively low stretch characteristics when heat set. There are two variations: a bright monofilament fibre and a softer, matt finish, spun yarn. Bright polyester fibres are low stretch, e.g. Braid on Braid EVO Bright Polyester. The spun yarn has less strength and is slightly stretchier but is kind to the hands. Spun yarn is typically used for the outer cover/jacket on, e.g. Matt Plait Polyester and TopGrip.

- Technora (Aramid) has superb Heat and Cut Resistance, making it the optimum fibre for hard work around winches - commonly blended into the outer cover/jacket on a doublebraid constructed line to provide protection against overheating, snagging and chafing.

- Dyneema (High Modulus Polyethylene) is denoted by an SK number. SK75 and SK78 are similar in strength and initial stretch. SK78 has the advantage of reduced creep (elongation over time). SK99 is the ultimate supreme specification. All three of these Dyneema grades can be super-pre stretched to deliver the highest strength and lowest stretch performance and impregnated with a protective polyurethane coating to provide excellent UV resistance. The price advantage over Vectran makes this a popular choice for rope manufacturers at the upper end of the performance range.

- Vectran is the strongest and most expensive fibre with very low creep (elongation over time) and is commonly impregnated with a UV-protective polyurethane.

Marlow Definitive Guide to Dyneema

Rope Construction

Braid on Braid, also known as Doublebraid

Running Rigging Lines generally comprise a braided outer cover (also known as a jacket) over a braided inner core. This is widely known as Braid on Braid or Doublebraid.

Image demonstrates the braided outer jacket construction on LIROS Herkules rope.

Image demonstrates the Marlowbraid construction.

Marlowbraid is the exception, featuring a different core with a gentle spiral inner strand structure, slightly reducing the stretch characteristic for a modest increase in price. The downside of this construction is that it tends to flatten around sheaves and winches. Marlowbraid requires a different splicing method.

Polyester is the universal rope fibre for running rigging lines because it is an all-round reliable performer for strength, stretch, abrasion and UV resistance. In 100% polyester lines, the amount of fibre is balanced equally between the cover and the core. The finished rope can be spliced using the doublebraid method

It is worth noting that some braided lines are available with a polypropylene core. This may make a saving, but it will be reflected in a marked lack of performance, particularly regarding a reduction in strength and an increase in stretch where it is not desirable.

The Outer Rope Cover, also known as the Jacket

The construction of the outer cover has a bearing on abrasion resistance.

Generally, a tighter weave or increased number of plaits offer a sliding scale of improved wear resistance as follows: 8plait, 16plait, 24plait, 1:1 plait, 32plait.

Conversely, the flexibility of the line will be affected the other way, with 8plait the most pliable and 32plait the least supple.

The Inner Rope Core

Polyester is the go-to fibre for cruising control lines.

Dyneema or Vectran have significantly increased strength and reduced stretch compared with polyester, and they are typically used in the core to enhance overall performance.

The disparity in strength between the polyester cover and the higher-tech core means that the rope requires a specific core-dependent splicing method to maintain strength and stability.

Dyneema and Vectran are much more expensive than polyester, so the price of the finished rope correlates directly to the proportion of Dyneema/Vectran content.

Consequently, the main difference between 'Cruising' and 'Racing' Dyneema will be the % Dyneema content in the core or the Dyneema SK rating. LIROS Cruising Dyneema Dynamic Plus has an intermediate braid between the cover and the inner core to offset the diminished SK78 Dyneema content.

The specification of Dyneema is also performance-critical, ranging from a relatively low SK38 (formerly used in Marlow D2 Club Cruising Dyneema) to SK75, SK78, and super-enhanced SK99.

Stripping the Cover

Halyards, sheets and control lines rely on the outer cover for grip and abrasion resistance in clutches and around winches.

To achieve a thinner, lighter line with maintained high load capability, the solution is to strip the cover from the core where grip and wear resistance are not so important. This can only be done with core-dependent ropes.

Performance Lines with Mid Jackets

Some Dyneema lines have an additional mid-layer jacket. Generally this is a thin layer that doesn’t provide strength to the line. It is cut away in the area of the line to be spliced to provide room within the main outer jacket to accommodate the extra fibres of the splice.

Image demonstrates LIROS Racer: the braided jacket covers the core dependent inner construction.

Blending Different Rope Fibres

Rope manufacturers have traditionally used different fibres for the core and the cover to make the most of their relative advantages.

However, they have found that even better ropes can be produced by blending different fibres together in the core or the jacket.

All the above fibres can be blended to achieve a specific performance attribute or to combine their 'Star Qualities' into the optimum cover e.g.

- Polypropylene/Dyneema blend - lightweight, Racing Performance sheets

- Technora/Polyester blend - hard-working Regatta Performance sheets that require enhanced heat, cut and chafe resistance around winches

- 100% Polyester, no blend - a close weave polyester cover will deliver reliable endurance for most cruising applications

Fibres are sometimes blended in the core to reduce weight or cost, e.g. Dyneema with Polypropylene.

Single Braid or Hollowbraid Construction

From right to left: LIROS D Pro Static, Marlow D12 Max 78, Lazyjack, LIROS Hollowbraid Floating Rope

These lines are not featured in the charts below, but they are worth a mention.

They are inexpensive to produce and easier to splice than braid on core or core-dependent lines.

Notable examples are Lazyjack and small-diameter control lines in 100% Polyester, Floating Safety Lines in 100% Polypropylene and last but not least, 12 Strand in 100% Dyneema

100% 12 Strand Dyneema Lines are available from Marlow and LIROS in SK78 and SK99 for control line applications requiring ultimate break load and minimal stretch. DM20 SK75 is available for static rigging applications, but DynIce Dux SK75 from Hampidjan is regarded as the world-leading solution in this field.

How does this help?

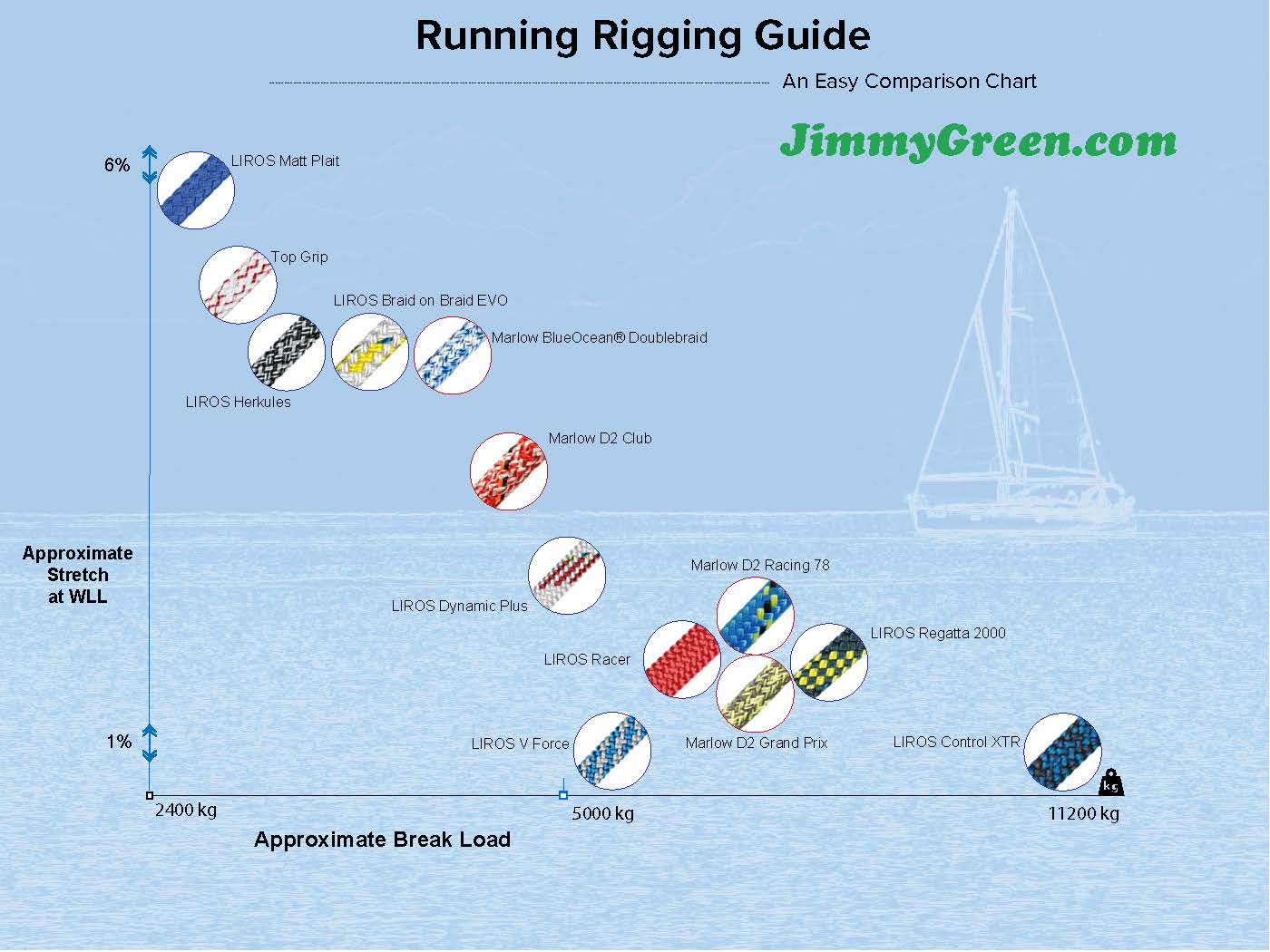

The full range of lines supplied by Jimmy Green Marine can cater for both cruisers and racers. We have arranged the lines on a sliding scale to help you decide where to aim.

Jimmy Green has a line for you whether you are a cruiser looking to strengthen your lines for a more adventurous voyage or a racer looking for top Regatta performance.

Rope Stretch Charts

| Type of Sailing | Rope Name | Cover | Mid Layer | Core | Stretch* |

|---|---|---|---|---|---|

|

Cruising ↕ Performance |

LIROS Matt Plait | 16-20 plait spun Polyester | N/A | 8 strand Polyester | < 6% |

| LIROS Top Grip | Tight weave 1:1 Plait Polyester with spun Polyester grip fibres | N/A | 8 strand Polyester | < 5% | |

| Marlow BlueOcean® Doublebraid | 24 plait RPet Recycled Polyester | N/A | 16 strand RPet Polyester | c 5% | |

| LIROS Herkules | Tight weave 1:1 plait Polyester | N/A | 8 strand Polyester | < 5% | |

| Marlowbraid | 16 plait Polyester | N/A | Loose-lay 3 strand Polyester | < 5% | |

| LIROS Braid on Braid EVO | 16-20 plait Polyester | N/A | 12 strand heat set Polyester | < 5% | |

| Marlow D2 Club | 16 plait Polyester | N/A | 12 strand SK75 Dyneema blended with Polypropylene | c 3% | |

| LIROS Dynamic Plus | 24-32 plait high-twist Polyester | 12 plait polyester | 12 strand SK78 Dyneema | < 2% | |

| Marlow D2 Racing | 24 plait Polyester | N/A | 12 strand SK78 Dyneema | c 1.5% | |

| LIROS Racer 2001 | 24-32 plait high-twist Polyester | Minimal 12 plait polyester | 12 strand SK78 Dyneema | < 1.5% | |

| LIROS Regatta 2000 | 24-32 plait high abrasion-resistant Polyester | Minimal 12 plait polyester | 12 strand SK78 Dyneema | < 1.5% | |

| Marlow GP78 | 20 plait Polyester/Technora blend | N/A | 12 strand SK78 Dyneema | c 1.5% | |

| LIROS V Force | 32 plait high-twist Polyester | N/A | 12 strand Vectran | < 1% | |

| LIROS Control XTR | 24-32 plait Polyester/Technora blend | N/A | 12 strand SK99 Dyneema | < 1% |

* Approximate Stretch at the safe working load of the line, nominally 25% of the breaking strain

c meaning approximately

< meaning less than

The Jimmy Green Cruising versus Performance Running Rigging Comparison Table (above) only focuses on lines constructed with a core and a cover.