Custom Build Instructions

The Jimmy Green Rigging Sales Team are very happy to help you to custom build and order products to your bespoke requirements.

There is a toggle to switch from Custom Build to a simple Cut Length where applicable.

Cut Length Rope Measurement Advisory

There are specific instructions to help you with the more complex custom products e.g. V and Y shape Bridles, Wire to Rope Halyards.

These are the general steps to follow to generate an instant quote and complete the order yourself.

- Make your selection for each available step - some are optional and can be left as they are, or restored to their original passive state.

- Remember to enter a length

Once you have made a selection from the drop down boxes available, the website will generate:

- a picture version of what you have chosen

- an overall length

- a price including VAT, or excluding VAT if you are signed in with an export delivery address

Video Tutorial

Jimmy Green Rigging Team Finished Length Advisory

The website will accept a length to 3 decimal points. However, this is not practicable for the majority of custom products.

There are specific detailed custom build instructions for different products e.g. rigging wires, mooring warps, webbing jackstays.

For critical applications produced from wire, the Jimmy Green Rigging Team aim for a bearing edge to bearing edge measurement which is accurate to within + or - the diameter of the wire.

For short finished rope lengths with a critical high load, super low stretch, control line application, the Jimmy Green Rigging Team aim for a bearing edge to bearing edge measurement which is accurate to within + or - the diameter of the rope. However, Jimmy Green Marine will only accept responsibility for bearing edge to bearing edge measurements to within 2 x + or - the diameter of the line.

For short strops and bridles with a splice at both ends, the Jimmy Green Rigging Team aim for a bearing edge to bearing edge measurement accurate to within 1%.

The finished length is checked in the measuring trough while the strop is pulled out straight, but not stretched tight with excessive force.

All ropes stretch to some extent under low load. Mooring and Anchoring ropes stretch more than most.

Therefore, although we aim for an accuracy of plus or minus 1%, 2% is more realistic, and Jimmy Green Marine can only accept responsibility for the finished length of a strop spliced at both ends to within a minimum tolerance of plus or minus 100mm.

Jimmy Green Marine can only accept responsibility for the final measurement to within these tolerances.

N.B. All rope and webbing stretches to some extent under load.

Please allow for stretch under load when determining your finished length.

If you add a compensator option, the length you order will still be the finished length, but the minimum achievable tolerance will be plus or minus 150mm

Jimmy Green Rigging Team Whipping Advisory

If you don't need a splice, a whipping is advisable to prevent the end from unravelling and to maintain the integrity of the rope construction.

We offer a heat sealing option which melts and moulds the end of the rope and the additional option of a heat shrink band, to keep the end of the line bound together.

However, these are only temporary solutions and a proper whipping is always recommended, to guarantee the integrity of the line.

Of course, we understand that you may wish to apply the finishing touch yourself, and we sell all the FIDS, TOOLS AND WHIPPING TWINES to add to your onboard service kit.

The Next Custom Build Steps:

- Check the item is designed as you wish - You can change any of your options and the website will update the picture and the price.

- Add any notes in the editable box provided, if required

- Check the quantity that you want to purchase and click the orange Add to Basket button to put it in your shopping basket.

- Select Continue Shopping or Proceed to Checkout.

- To view the items you have selected, go to your basket or direct to checkout.

Additional Notes for your Custom Build

You can add a note for your own benefit or to advise the Rigging Team of a specific requirement.

This note will appear in the product description in your basket

Common examples:

- Add a name for identifying your selection

- Splice on a fitting that is not in the custom build drop down menu

- Request a different loop length

Jimmy Green Advisory when adding a fitting where a finished length is critical - it is essential to make it clear whether the finished length should be measured to the bearing edge of the additional fitting.

The Jimmy Green Rigging Team Finished Length Process

- Splice or terminate one end

- Secure the finished end to a bearing edge pin

- Lay the the wire, rope or webbing out straight against the fixed tape measure

- Calculate and mark the bearing edge point for the termination at the other end

- Finish the second end

- Check the finished, bearing edge to bearing edge length against your order

Quality Control

The Jimmy Green Rigging Team undertake to check the rope, wire or webbing meticulously during the production process, to ensure that it is 100% First Quality.

The Jimmy Green Despatch Team make a second thorough quality inspection of each item, including a careful check that it matches your order, before packing it into your parcel.

Additional Information

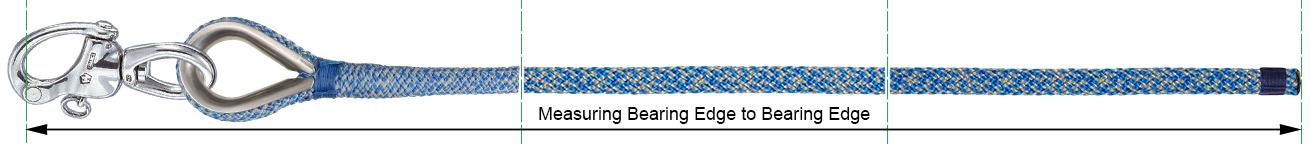

The finished length is measured from the bearing edge to the bearing edge = the inside face of a loop/thimble where a shackle pin would take the load and therefore NOT the overall outside length.

The splicing price includes the extra rope required to make the splice and meet the overall finished length.

The wire terminal price includes the hydraulic termination process, either Cabco Talurit Press or Wire Technik Roller Swaging.

Please take extra care when ordering because once a bespoke item has been started (cut) it can neither be cancelled or returned for a refund.