- -20%

More Information

Downloads

SIDERMARINE are a technologically innovative manufacturer of stainless-steel components based in Bari, Italy.

SIDERMARINE are a technologically innovative manufacturer of stainless-steel components based in Bari, Italy.

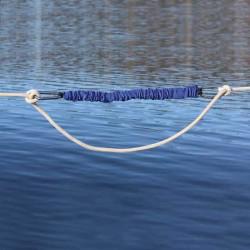

The MPP Top Series of Shock Absorbing Mooring Springs are a SIDER patented design which delivers a 60%-70% damping effect.

MPP/T Mooring Springs are constructed from a special stainless-steel alloy with replaceable Mollaflex Elastomer shock absorbing inserts.

MPP Top Series Mooring Spring Facts and Plus Factors:

- Patented Design

- Exceptional elasticity

- Superior Corrosion Resistance

- Special Stainless-Steel Alloy

- Mollaflex Elastomer integral cushioning inserts

- Anti-squeak, anti-friction bushes

- Silent motion – no audible annoyance

- 60%-70% Shock Absorption

- Superior Damping Capacity

- Wide range of sizes to suit all sail and motorboats

- SIDERMARINE publish a manufacturer minimum break load for reassurance

SIDERMARINE Data:

| SIDERMARINE | Boat Length | Wire Ø | Spring Ø | MDF | Inserts | MBL |

|---|---|---|---|---|---|---|

| MPP/T007 | < 9 metres | 7mm | 74mm | 260kg | 2 | 3000kg |

| MPP/T008 | 8-11 metres | 8mm | 76mm | 325kg | 4 | 4000kg |

| MPP/T009 | 9-12 metres | 9mm | 76mm | 455kg | 4 | 6000kg |

| MPP/T010 | 10-16 metres | 10mm | 80mm | 611kg | 4 | 10000kg |

| MPP/T012 | 16-25 metres | 12mm | 100mm | 975kg | 4 | 20000kg |

MDF = Manufacturer Damping Force

MBL = Manufacturer rated break load

| SIDERMARINE | Boat Length | Boat Weight ** |

|---|---|---|

| MPP/T007 | < 9 metres | 1800kg |

| MPP/T008 | 8-11 metres | 2400kg |

| MPP/T009 | 9-12 metres | 3600kg |

| MPP/T010 | 10-16 metres | 6000kg |

| MPP/T012 | 16-25 metres | 12000kg |

** See SiderMarine caveat below

SIDERMARINE Advisory on Model Selection

The loads of cushioning (Damping force) are increased in the models with inserts Mollaflex-Elastomer.

It is recommended to use the model of the upper range when it is at the limit of the band.

For the correct assessment of the purchase of the mooring spring suitable for your boat, you must report the weight of the boat to value of the breaking load less than 30-40%.

Sidermarine exonerates from any responsibility or replacement under warranty in case of purchase of a spring not suitable for the weight of the boat and therefore undersize.

Jimmy Green Interpretation of the SiderMarine Data

- The Damping force is increased in the models with Mollaflex-Elastomer cushioning inserts.

- Select the next model up when your boat is near the limit as described above.

- The displacement of your boat or yacht should be no greater than 60%-70% of the Mooring Spring rated break load.

- Sidermarine exonerate themselves from any responsibility or replacement under warranty if a spring is undersize.

N.B. If you are in any doubt regarding which size you require, the Sidermarine published data is available to view in the Download tab above

SIDERMARINE Advisory on Installation and Care

- The mooring springs can't be immersed in sea water, for a long time, without an anode protection (sacrificial zinc) as well as, as a rule, those used on the propeller shafts. In the absence of such compliance, SPRING WILL BE, in a short time, OBJECT OF SHAPES OF LOCALIZED CORROSION (see definition and list of types of "localized corrosion" on internet or on the retailer's indication)

- Do not use chains for mooring which, immersed in sea water, can be excellent conductors of galvanic currents - stray currents, but suitable cordage. In the absence of such compliance, SPRING WILL BE, in a short time, OBJECT OF SHAPES OF LOCALIZED CORROSION (see definition and list of types of "localized corrosion" on internet or on the retailer's indication)

- At first use, lubricate the guides and the rods tie with spray grease for boating.

- After 6 months check the wear of the guides and lubricate.

- Check the locking of the tie rod nuts after 12 months.

- Check the wear of the friction guide and replace if necessary and lubricate

Jimmy Green Interpretation of the Sidermarine Data

- Set up your mooring spring to avoid permanent immersion in sea water

- Combine the spring with suitable nylon or polyester mooring rope

- Connect the spring to the rope or chain with stainless steel shackles

- Use stainless steel chain around the mooring bollard

- Lubricate the springs with marine approved waterproof spray grease

- Check the springs/inserts regularly for signs of wear or loosening

- Replace the inserts if they are worn

- Lubricate regularly with marine approved waterproof spray grease

Jimmy Green Rigging Team Advisory

- Attach a slack warp alongside the spring as a security measure.

- Deploy a second, independent mooring line for reassurance.

These precautions are especially important when the yacht is left unattended for long periods.